Large-field splicing exposure machine

A spliced, large field of view technology, applied in optomechanical equipment, microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problem of increasing the cost of the lighting system, proportionally increasing the size of the unit pixel, and reducing the projection area. minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

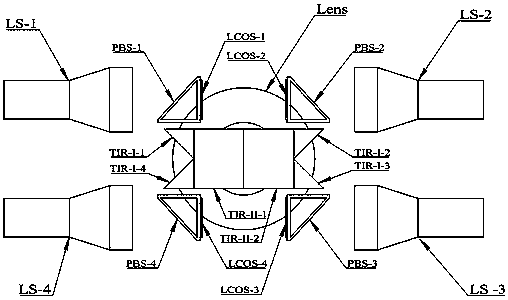

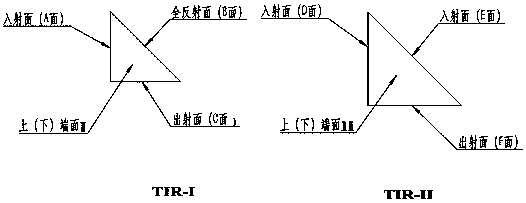

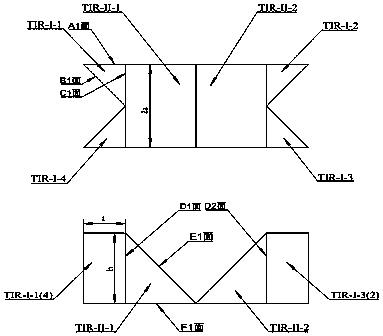

[0011] The system consists of an imaging lens Lens, four pieces of silicon-based liquid crystals of the same specification, namely LCOS-1, LCOS-2, LCOS-3 and LCOS-4, and four pieces of polarization beam splitters, namely PBS-1, PBS-2, PBS-3 And PBS-4, four I-type right-angle triangular total reflection prisms TIR-I-1, TIR-I-2, TIR-I-3 and TIR-I-4 with the same specifications, two II-type right-angle triangles with the same specifications Composed of total reflection prisms TIR-II-1 and TIR-II-2, four light sources LS-1, LS-2, LS-3 and LS-4.

[0012] The overall system structure is attached figure 1 As shown, light sources LS-1, LS-2, LS-3 and LS-4 pass through PBS-1, PBS-2, PBS-3 and PBS-4 respectively to LCOS-1, LCOS-2, LCOS-3, LCOS -4 independent lighting, LCOS-1, LCOS-2, LCOS-3 and LCOS-4 combined with PBS-1, PBS-2, PBS-3 and PBS-4 respectively, the angle between PBS and LCOS photosensitive surface is 45° , PBS-1, PBS-2, PBS-3 and PB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com