Component nonuniformity numerical prediction method for magnesium alloy casting parts

A technology for numerical prediction and casting, which is used in electrical digital data processing, special data processing applications, instruments, etc. It can solve the problems of inability to accurately predict macrosegregation of magnesium alloy castings and uneven composition of magnesium alloy castings, and achieve market applications. Great potential to accurately predict the effects of segregation formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Embodiment 1: In this embodiment, a method for numerically predicting the compositional inhomogeneity of magnesium alloy castings has a specific process as follows:

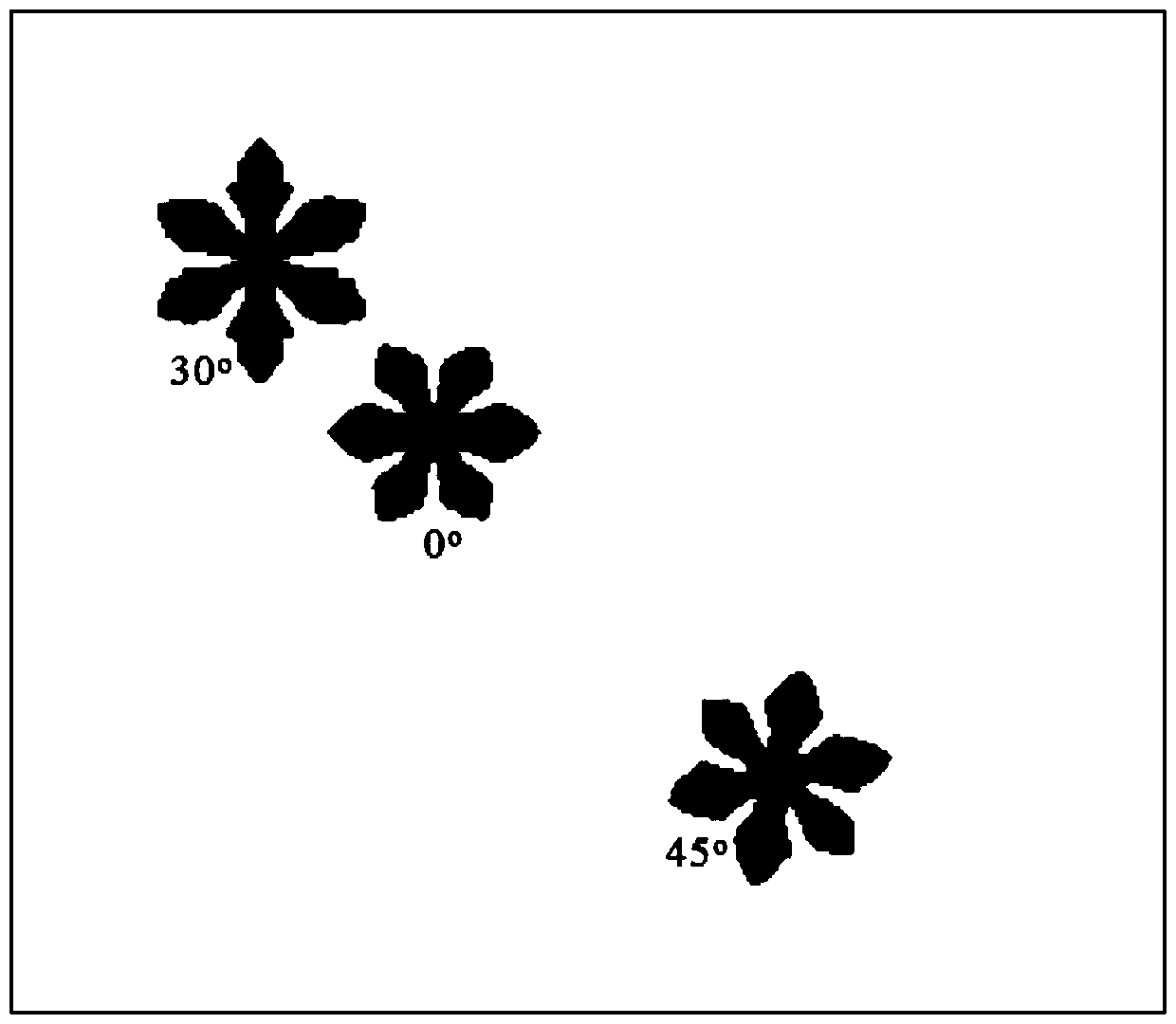

[0037] Step 1, using the cellular automata method to simulate the growth of α-Mg dendrites with different growth orientations, and obtaining the dendrite specific surface area versus solid phase fraction variation curve;

[0038] Step 2. Carry out macro-scale grid division for the casting system, and adopt the same grid division step size Δx meters=Δy meters for the X-axis and Y-axis directions of the casting system Cartesian coordinate system;

[0039] Δx=X max -Xmin , Δy=Y max -Y min ;

[0040] The calculation label is (js, ks) char The subscript char=2 indicates the casting grid, the subscript char=0 indicates the casting grid, and the subscript char=4, 5, 6, 7 and 8 respectively indicate the internal cooling iron grid and the external cooling iron grid grid, riser sleeve grid, thermal insulation m...

specific Embodiment approach 2

[0048] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the cellular automata method is used to simulate the growth of α-Mg dendrites with different growth orientations in the step 1, and the dendrite specific surface area varies with the solid phase fraction. Change curve; the specific process is:

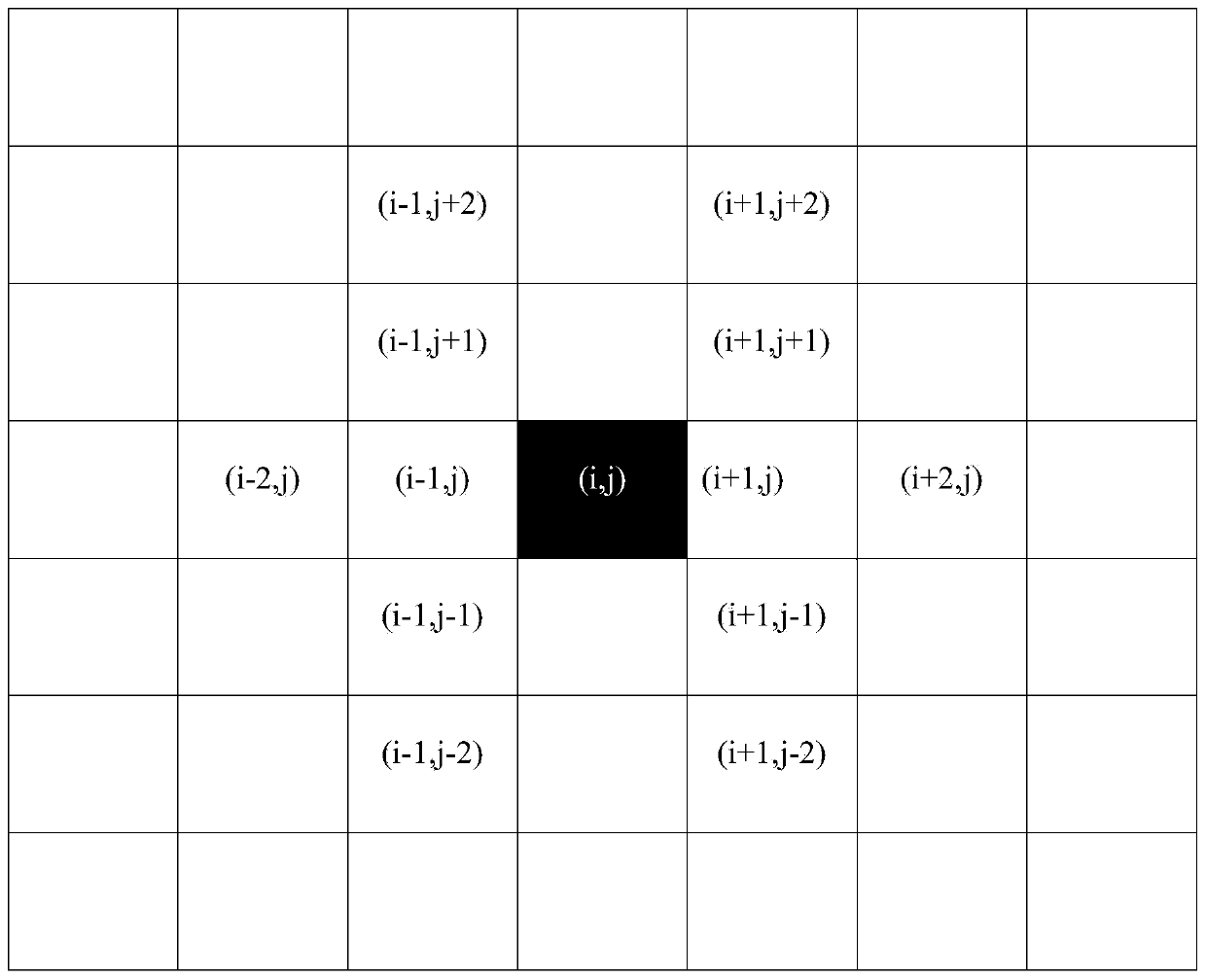

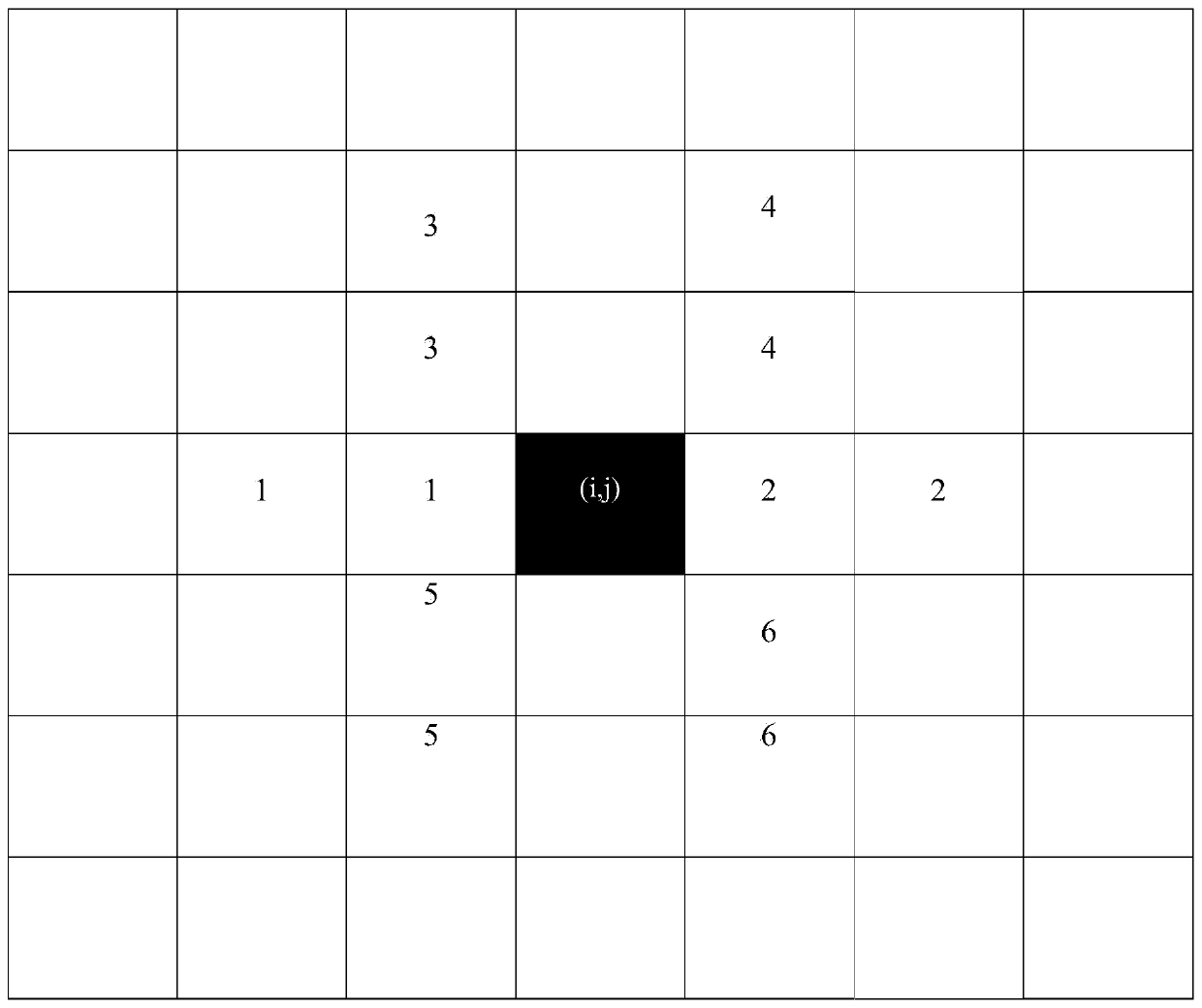

[0049] Step 1 (1), divide the dendrite growth calculation domain (already determined) into a micro-scale grid, using a square grid with a side length of Δstep, and each square grid is marked with (j, k), j The value range of k is [1, n], the value range of k is [1, m], j and k are integers, n and m are integers, j is the coordinate on the X-axis of the Cartesian coordinate system, k is the coordinate on the Y axis of the Cartesian coordinate system;

[0050] Step 1 (2), assign neighbor objects to each square grid in the computational domain, and complete dendrite growth by capturing neighbor objects;

[0051] The labels are (j∈[1,2]...

specific Embodiment approach 3

[0080] Specific embodiment three: what this embodiment is different from specific embodiment one or two is, in described step one (3), determine the state of each square grid in the solidification process; Concrete process is:

[0081] The boundary grid defined in step 1 (2) can only be in a liquid state, that is, state (j, k) = 0, and state is the state of the grid; the remaining grids have three states:

[0082] when f s When (j, k) = 0, the grid (j, k) is liquid, that is, state (j, k) = 0;

[0083] When 0s When (j, k)<1, the grid (j, k) is in a growing state, that is, state(j, k)=1;

[0084] when f s (j, k) = 1 and the pairing grid (pairing is the following 1-6 pairing method) f s is also equal to 1, then the grid (j, k) is solid, that is, state (j, k) = 2;

[0085] f s (j, k) is the solid phase fraction of the grid (j, k) (the solid phase fraction of the grid (j, k) that divides the dendrite growth calculation domain (already determined) into a micro-scale grid).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com