Water-soluble solid aromatherapy product and preparation method thereof

A water-soluble, solid-state technology, applied in the direction of atomizing substances, deodorization, disinfection, etc., can solve the problems of no rattan aromatherapy solid-state aromatherapy products, affecting the use effect and durability of use, waste of auxiliary materials and resources, etc., to improve the use effect And use durability, improve use safety, increase the effect of persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

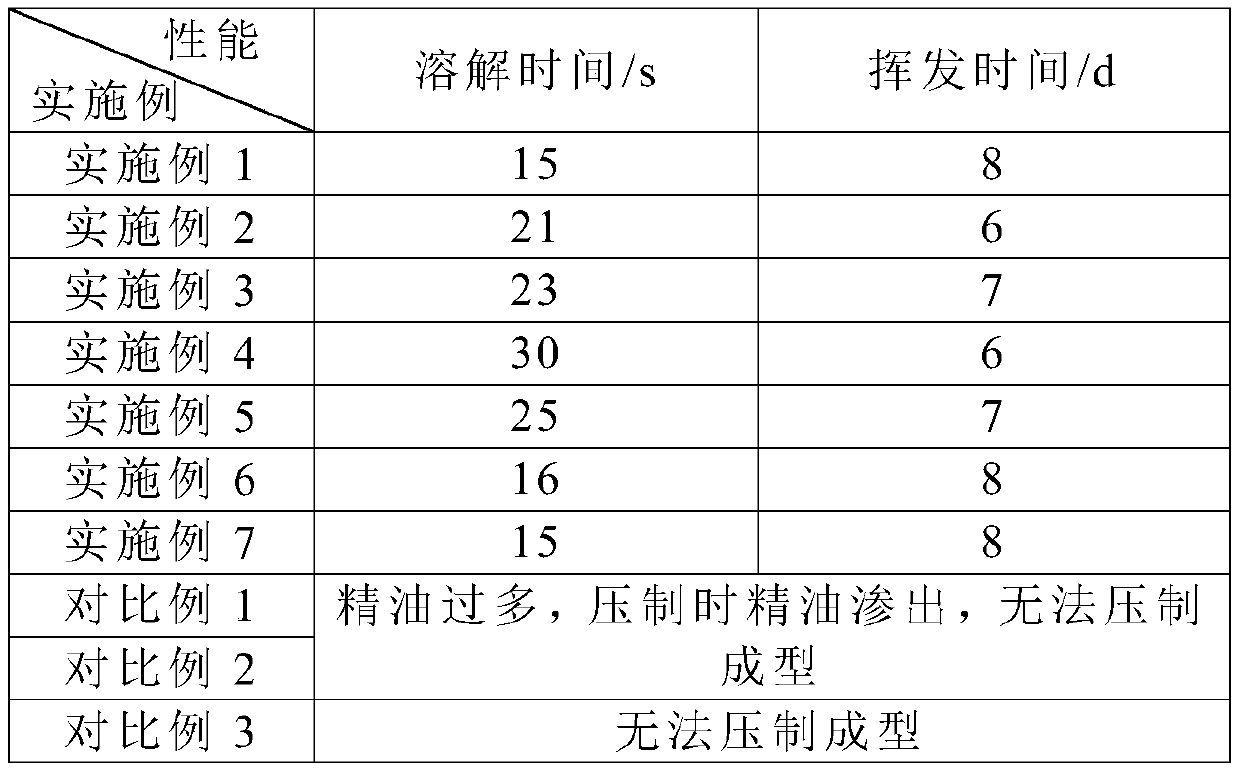

Examples

Embodiment 1

[0048] Grind citric acid and sodium bicarbonate into powder first, and sieve through a sieve, take powdered solid acid agent and sodium bicarbonate in the range of 100-200 mesh particle size, and then use 22.5 parts of citric acid in parts by weight , 17.5 parts of sodium bicarbonate, 35 parts of lactose and 2 parts of mannitol are mixed, then add 20 parts of essential oil, mix well, and finally add 3 parts of PEG-6000, mix well, place in a mold for compression molding, dry, and heat shrink packaging.

[0049] Among them, 20 parts of essential oils include 5 parts of lavender oil and 15 parts of spearmint oil; the above-mentioned steps are all carried out under constant temperature and humidity conditions of 22°C and 40% humidity except for the drying step, and the drying is at 52°C for 12 hours .

Embodiment 2

[0051] Grind citric acid and sodium bicarbonate into powder first, and sieve through a sieve, take powdered solid acid agent and sodium bicarbonate with a particle size range of 100 to 200 mesh, and then use 25 parts of citric acid in parts by weight , 20 parts of sodium bicarbonate, 33 parts of lactose and 4 parts of mannitol are mixed, then 13 parts of essential oil are added, mixed evenly, and finally 5 parts of PEG-6000 are added, after mixing, they are pressed into molds, dried, and shrink-wrapped.

[0052] Among them, 13 parts of essential oils include 3 parts of sweet orange oil and 10 parts of rose oil; the above-mentioned steps are all carried out under constant temperature and humidity conditions of 26°C and 43% humidity except for the drying step, and the drying is at 53°C. 12h.

Embodiment 3

[0054] Grind citric acid and sodium bicarbonate into powder first, and sieve through a sieve, take powdered solid acid agent and sodium bicarbonate with a particle size range of 100-200 mesh, and then use 21 parts of citric acid in parts by weight , 17 parts of sodium bicarbonate, 40 parts of lactose and 3 parts of mannitol are mixed, then 16 parts of essential oil are added, mixed evenly, and finally 3 parts of PEG-6000 are added, after mixing, they are pressed into a mold, dried, and shrink-wrapped.

[0055]Among them, 16 parts of essential oils include 15 parts of sweet orange oil and 1 part of tea tree oil; the above-mentioned steps are all carried out under constant temperature and humidity conditions at 21°C and 35% humidity except for the drying step, and the drying is at 51°C. 13h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com