A continuous flow photochemical reactor

A technology of chemical reactor and photochemical reaction, which is applied in the field of photochemical reaction, can solve problems such as difficulty in realizing industrialized production, low product yield, and many side reactions, and achieve the effects of improving utilization rate, reducing device volume, and convenient parts replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

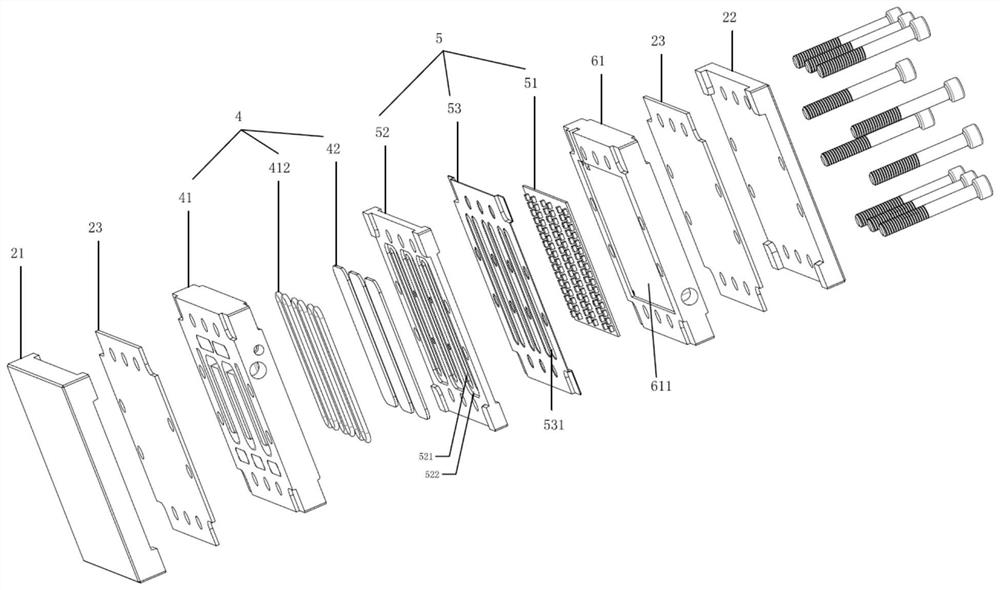

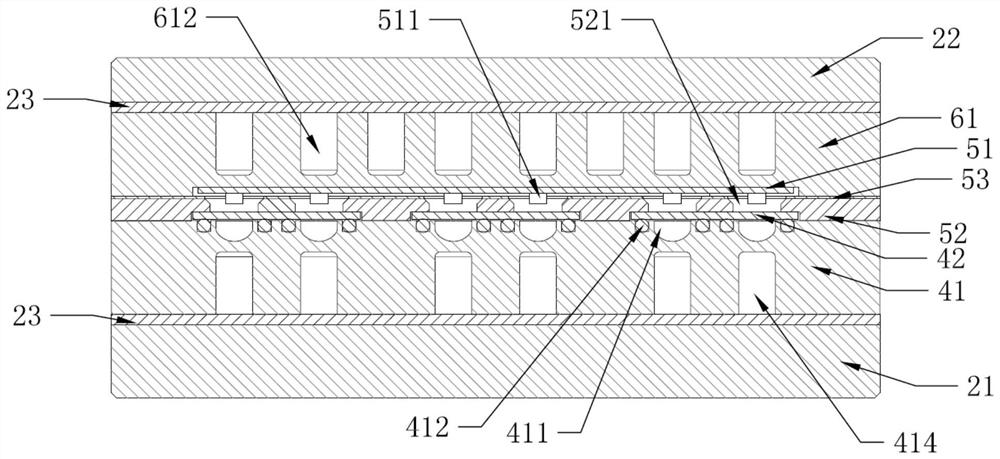

[0041] The present embodiment provides a compact continuous streamer type chemical reactor, comprising a reaction chamber for a photochemical reaction, a reaction chamber temperature control temperature control chamber and the control chamber of the light source for control. like figure 1 with Image 6 Shown, the reaction chamber 1 comprises a housing and a reactor module located inside the housing 2, the reactor module 2 comprises a photochemical reaction unit 4 is provided outside the light source module photochemical reaction unit 5, heat dissipating module and a light source, reactant temperature control module.

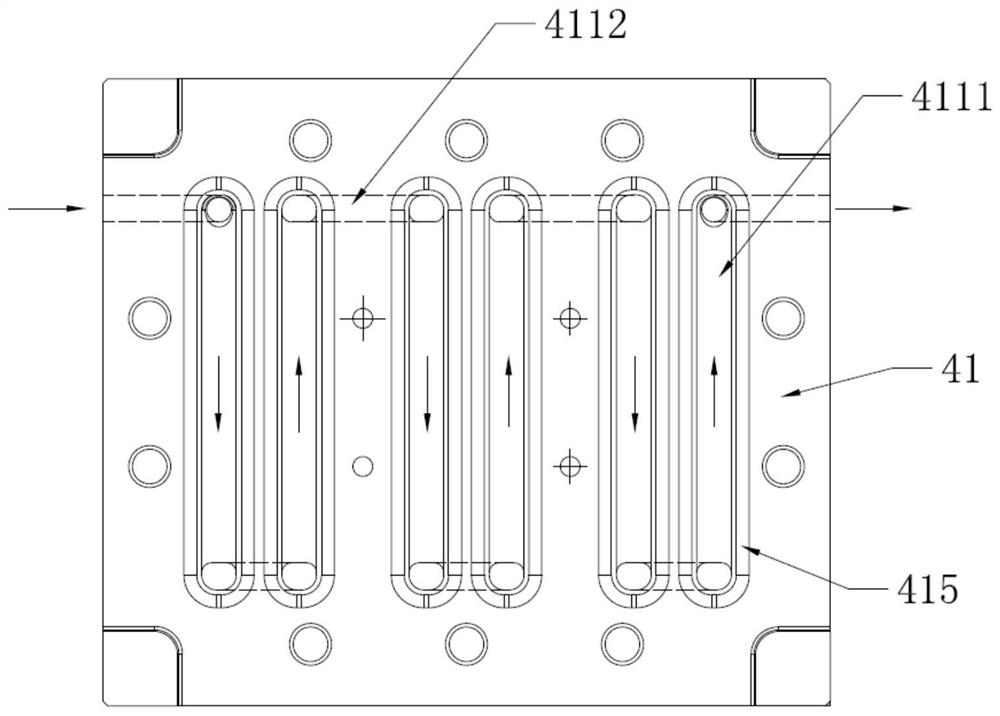

[0042] like Figure 1-2 , The reactor module 2 comprises a reaction chamber 41 disposed sequentially stacked plate, a quartz glass plate 42, cover plate 52 fixed to a quartz plate, insulating pads 53, the light source panel 51. The light source panel 51 of the outer plates 41 and the reaction chamber are respectively provided temperature control module and a light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com