Multifunctional ion exchange resin regeneration cleaning column

An ion exchange resin, a multifunctional technology, applied in the field of ion exchange, can solve the problems of ineffective discharge of suspended solids, artificial structure required for resin transfer, and inability to fully discharge resin, etc., to achieve convenient resin transfer, simple structure, and no resin retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

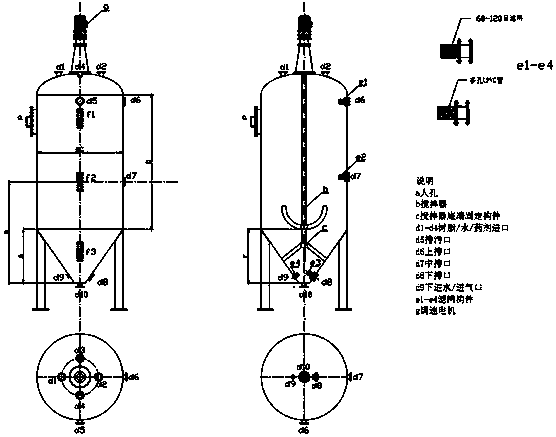

[0017] Below according to accompanying drawing and embodiment this patent is described further:

[0018] In order to achieve the above object, the present invention adopts the following scheme: a multifunctional ion exchange resin regeneration cleaning column, including a sealing column 1, an agitator b, a speed regulating motor g, and a fixed member c at the bottom of the agitator. The resin is firstly injected into the sealing cylinder 1 through the ports d1-d4, and then the regeneration solution is injected from the lower inlet d9, and flows out from the middle outlet d7, so that the high-concentration regeneration solution can be collected. Afterwards, the speed-regulating motor g connected to the agitator b inside the sealed cylinder 1 is turned on, and the motor speed can be adjusted manually or automatically to adjust the stirring speed for different resins. After stirring evenly, pass through the upper outlet d6 for countercurrent cleaning and drainage of the resin. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com