A corrosion inhibitor coating film pig for high sulfur-containing wet gas gathering and transportation pipeline

A technology for gathering and transporting pipelines and corrosion inhibitors, which is applied to coatings, cleaning hollow objects, cleaning methods, and utensils. It can solve problems such as uneven distribution, corrosion inhibitor coating film thickness, and coating film quality decline. Safe and smooth effect of the ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

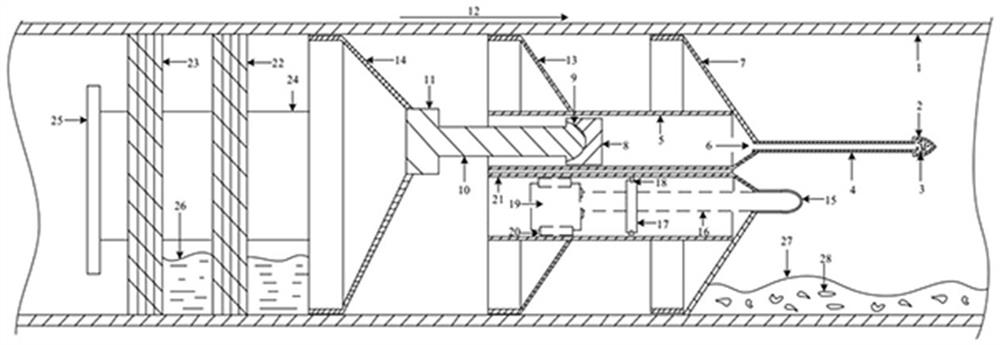

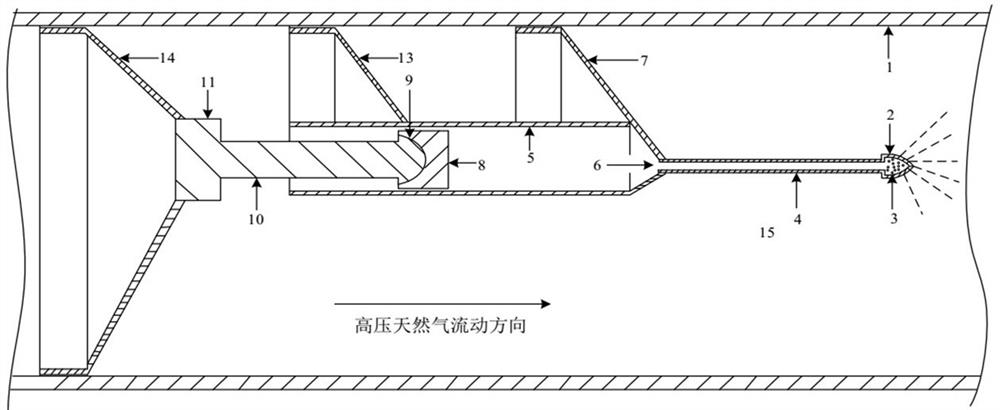

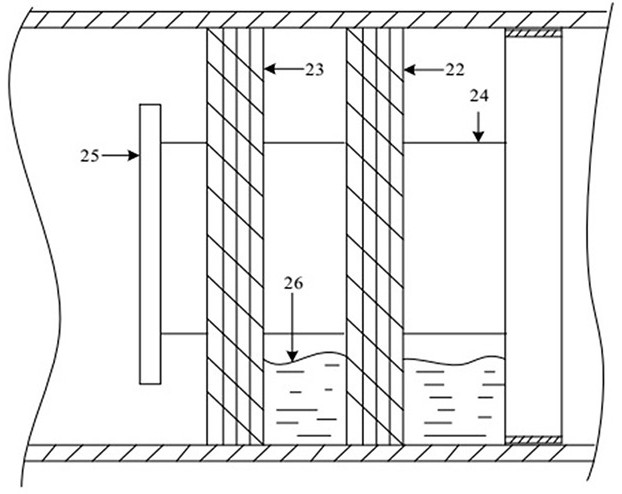

[0035] In this example, figure 1 It is a schematic structural diagram of a corrosion inhibitor coated film pig for a high-sulfur wet gas gathering and transportation pipeline. Including pipeline inner wall 1, corrosion inhibitor nozzle 2, nozzle orifice 3, corrosion inhibitor delivery pipeline 4, corrosion inhibitor storage chamber 5, corrosion inhibitor delivery pipeline inlet 6, first sealing cup support 7, movable piston 8. Piston front end 9, piston rod 10, piston base 11, natural gas flow direction 12, second sealing cup support 13, third sealing cup support 14, expandable unit 15, explosion-proof power line 16, explosion-proof controller 17, First support member 18, explosion-proof power supply 19, second support member 20, chemical reagent storage chamber 21, first corrosion inhibitor coating circular brush 22, second corrosion inhibitor coating circular brush 23, support frame 24 , fixed flange 25, corrosion inhibitor solution 26, liquid impurities 27, solid impuritie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com