Angle welding process for automatic submerged-arc welding and welding tool used thereby

A submerged arc automatic welding and welding tooling technology, which is applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems that it is difficult to meet the angle requirements of the grooved bulkhead, it is difficult to prevent welding deformation, and the amount of tooling materials is large. , to achieve the effect of good surface forming effect, less welding labor intensity and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

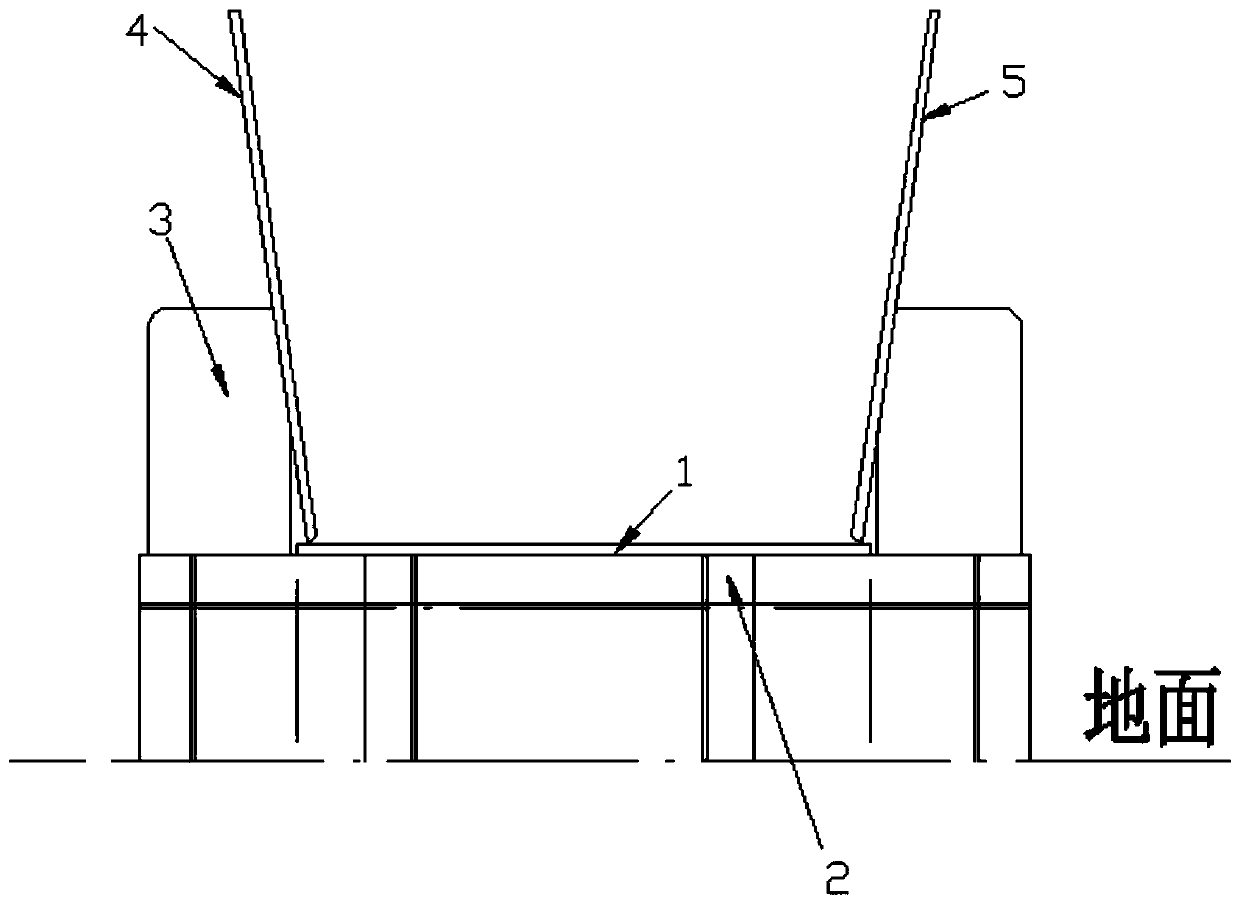

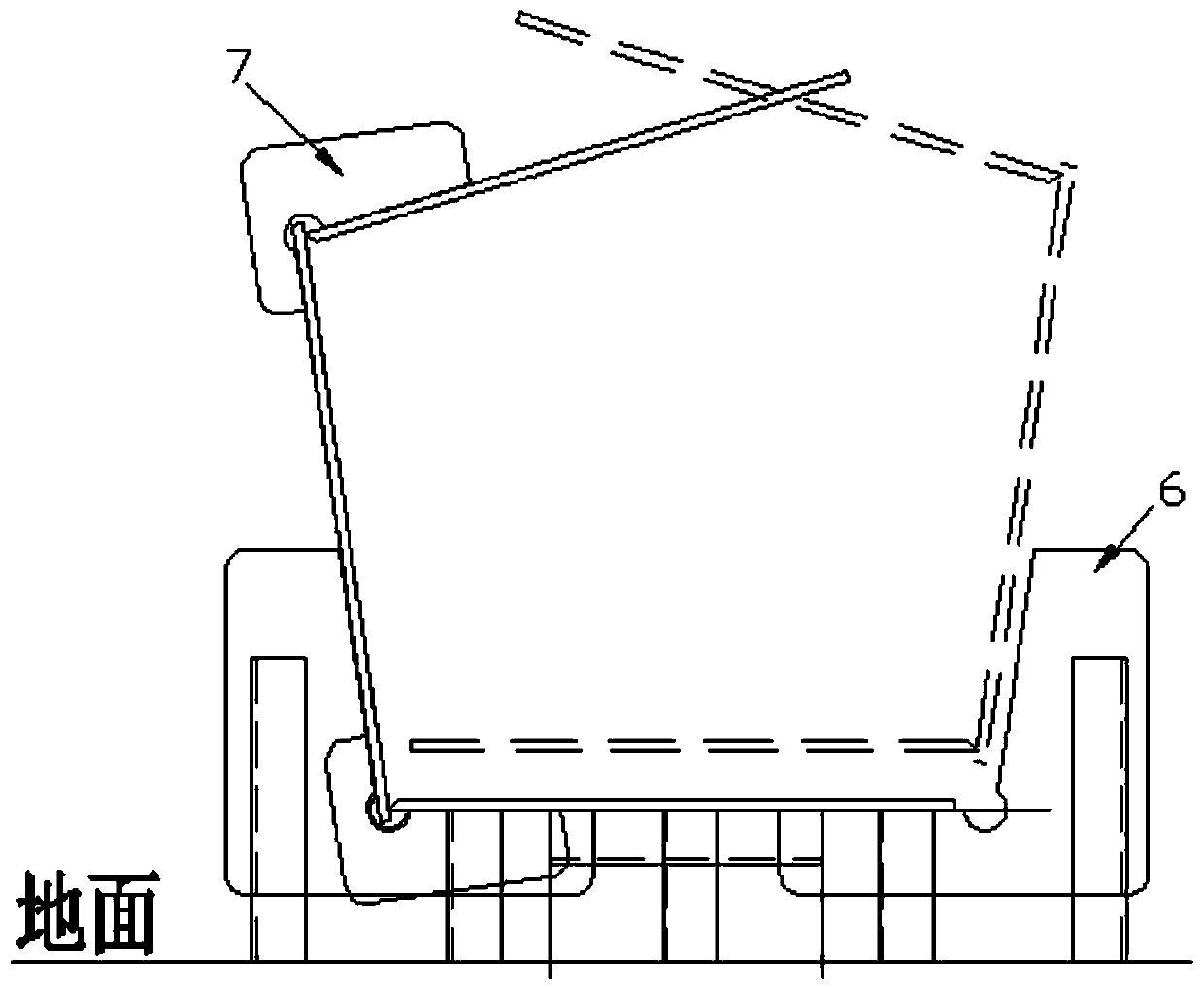

[0025] Such as Figure 1 to Figure 6 as shown ( image 3 The dotted line corresponds to the schematic diagram of steps S4 and S5), the present invention is a submerged arc automatic fillet welding process, comprising the following process steps:

[0026] S1: First place the bottom plate 1 of the three wall plates of the corrugated bulkhead on the tire frame made of angle steel 2, and then place several pairs of welding templates 3 arranged in pairs on the tire frame. The templates 3 are arranged symmetrically and two of each pair are respectively located on the left side of the left side wall 4 and the right side of the right side wall 5, and then the bottom plate 1, the left side wall 4 and the right side wall 5 are assembled together ;

[0027]S2: Hoist the assembled corrugated bulkhead and turn over to the position where the left side wall 4 or right side wall 5 is located below, and place the corrugated bulkhead on the lower left side wall 4 or right side wall 5 placed ...

Embodiment 2

[0034] The only difference from Embodiment 1 is that the angle between the left side wall plate and the bottom plate is 115°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com