HEC/PVA interpenetrating network aerogel and preparation method thereof

An interpenetrating network and aerogel technology, applied in the field of HEC/PVA interpenetrating network aerogel and its preparation, can solve the problems of low recovery, few recycle times, poor mechanical properties of aerogel, etc. High recovery performance, good biodegradability, and the effect of many cycles of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

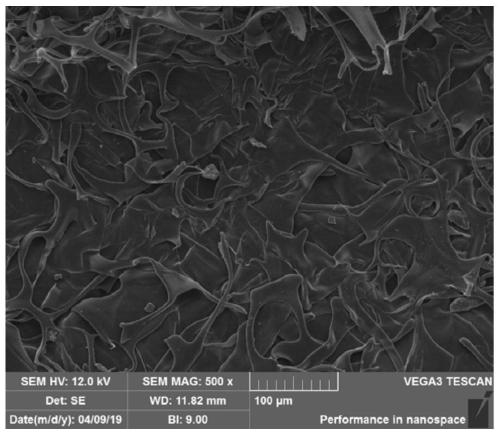

Image

Examples

preparation example Construction

[0025] The present invention provides a kind of preparation method of HEC / PVA interpenetrating network airgel, comprises the following steps:

[0026] Step 1, mixing polyisocyanate and nano-cellulose microcrystalline solution, stirring to obtain a uniform milky white mixed solution;

[0027] Wherein, the polyisocyanate and the nanocellulose microcrystalline solution are mixed in a mass ratio of (1-3): 100; the polypolyisocyanate adopts water-soluble blocked polyisocyanate; the mass percentage of the nanocellulose microcrystalline solution is 1%. -3%; nanocellulose microcrystal solution is used to mix nanocellulose microcrystals with water and stir until a uniform light blue solution is obtained.

[0028] Step 2. Mix the mixed solution with the hydroxyethyl cellulose solution, stir, and ultrasonically degas to obtain the HEC / CNC / polyisocyanate solution; the mass ratio of the mixed solution to the hydroxyethyl cellulose solution is 1: (10-20) The ratio is mixed; the mass percen...

Embodiment 1

[0032] A kind of preparation method of HEC / PVA interpenetrating network airgel of the present invention, comprises the following steps:

[0033] Step 1. Mix hydroxyethyl cellulose with deionized water, let it stand for swelling for 1 hour, and stir to prepare a 1% hydroxyethyl cellulose solution by mass;

[0034] Step 2, mixing nanocellulose microcrystals with deionized water, stirring until a uniform light blue solution is obtained, and preparing a nanocellulose microcrystal solution with a mass percentage of 1%;

[0035] Step 3, mixing polyisocyanate with the nanocellulose microcrystalline solution in step 2 in a mass ratio of 1:100, stirring until uniform milky white is present, to obtain a mixed solution;

[0036] Step 4. Mix the mixed solution in step 3 with the hydroxyethyl cellulose solution in step 1 in a mass ratio of 1:10, stir, and ultrasonically degas for 0.5 h to obtain HEC / CNC / polyisocyanate solution;

[0037] Step 5. Place the HEC / CNC / polyisocyanate solution in...

Embodiment 2

[0044] A kind of preparation method of HEC / PVA interpenetrating network airgel of the present invention, comprises the following steps:

[0045] Step 1. Mix hydroxyethyl cellulose and deionized water, let it stand for swelling for 3 hours, and stir to prepare a hydroxyethyl cellulose solution with a mass percentage of 1.5%.

[0046] Step 2, mixing the nanocellulose microcrystals with deionized water, stirring to a uniform light blue solution, and preparing a nanocellulose microcrystal solution with a mass percentage of 1.5%;

[0047] Step 3, mixing polyisocyanate with the nanocellulose microcrystalline solution in step 2 in a mass ratio of 1.5:100, stirring until uniform milky white is present, to obtain a mixed solution;

[0048] Step 4. Mix the mixed solution in step 3 with the hydroxyethyl cellulose solution in step 1 in a mass ratio of 1:15, stir, and ultrasonically degas for 0.7 hours to obtain HEC / CNC / polyisocyanate solution;

[0049] Step 5. Place the HEC / CNC / polypolyiso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com