Production method for reducing calcium aluminate inclusions in aluminum killed steel

A calcium-aluminate and aluminum-killed steel technology, which is applied in the manufacture of converters, etc., can solve the problems of residual, small amount of calcium-treated products, and lack of effective collision, etc., and achieve simple process and reduce the large particle size of calcium-aluminate Inclusions, the effect of improving the quality of molten steel and product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

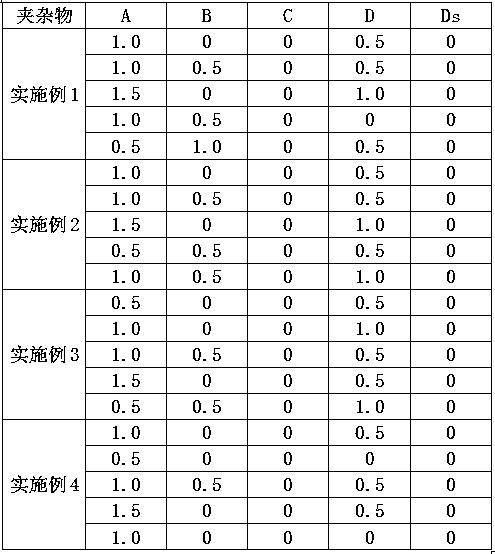

Embodiment 1

[0014] Embodiment 1: The specific process of the production method for reducing calcium-aluminate inclusions in aluminum-killed steel is as follows.

[0015] 40Cr is smelted, the end point C of the converter is 0.12%, the tapping temperature is 1600°C, and the slag is blocked by the sliding plate to tap; 3.7kg / t lime and 1.18kg / t bauxite are added after the furnace for slag modification; the tapping process is bottom-blown For argon, 1.2kg / t of aluminum block, 4.5kg / t of silicomanganese and 13.4kg / t of ferrochrome are added sequentially when tapping 20t of steel, and the oxygen position after argon is 60ppm. LF enters the station to heat up and produce white slag. After producing white slag, feed 0.08kg / t aluminum-calcium cored wire into the ladle for final deoxidation of molten steel. After the soft blowing is completed, before the ladle is cast on the machine, feed 0.03kg / t pure calcium wire into the ladle to treat the molten steel with Ca, and then cast it on the machine; t...

Embodiment 2

[0016] Embodiment 2: The specific process of the production method for reducing calcium-aluminate inclusions in aluminum-killed steel is as follows.

[0017] Smelting 35K, converter end point C is 0.09%, tapping temperature 1648°C, sliding plate slag blocking tapping; 5.0kg / t lime and 0.9kg / t bauxite are added after the furnace for slag modification; bottom blowing throughout the tapping process For argon, 1.6kg / t of aluminum block, 4.95kg / t of silicomanganese and 1.0kg / t of ferromanganese and other alloys are sequentially added when tapping 28t, and the oxygen position after argon is 53ppm. LF enters the station to heat up and produce white slag. After producing white slag, feed 0.07kg / t aluminum-calcium cored wire into the ladle for final deoxidation of molten steel. After the soft blowing is completed, before the ladle is cast on the machine, feed 0.01kg / t pure calcium wire into the ladle to treat the molten steel with Ca, and then cast it on the machine; the temperature of...

Embodiment 3

[0018] Embodiment 3: The specific process of the production method for reducing calcium-aluminate inclusions in aluminum-killed steel is as follows.

[0019] Smelting 35K, converter end point C is 0.06%, tapping temperature 1680°C, sliding plate slag blocking tapping; 6.3kg / t lime and 0.7kg / t bauxite are added after the furnace for slag modification; bottom blowing throughout the tapping process For argon, 2.4kg / t of aluminum block, 5.3kg / t of silicomanganese and ferromanganese and other alloys are sequentially added when tapping 30t, and the oxygen position after argon is 40ppm. LF enters the station to heat up and produce white slag. After producing white slag, feed 0.04kg / t aluminum-calcium cored wire into the ladle for final deoxidation of molten steel. After the soft blowing is completed, before the ladle is cast on the machine, feed 0.04kg / t pure calcium wire into the ladle to treat the molten steel with Ca, and then cast it on the machine; the temperature of the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com