Preparation method of pure copper-brass composite wire of soft/hard filiform structure

A technology of composite wire and pure copper, which is applied in the field of preparation of soft/hard filamentary structure pure copper-brass composite wire, can solve the problems of limited interface strengthening, low material utilization, poor interface bonding, etc., and achieve interface bonding Excellent performance, strong process controllability, and high interface ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First, the following equipment is used in this embodiment: high temperature diffusion pressure welding equipment, rotary forging equipment, heat treatment tube furnace.

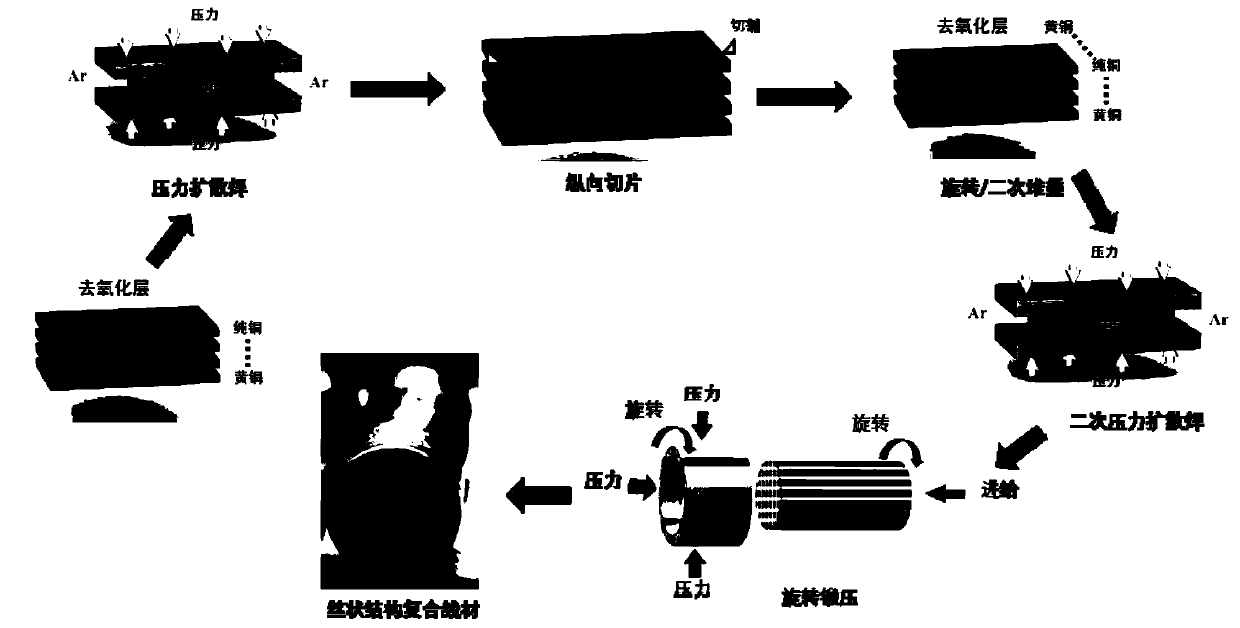

[0033] The process flow chart of preparing a pure copper-brass composite wire rod in this embodiment is as follows figure 1 As shown, the specific operation is as follows:

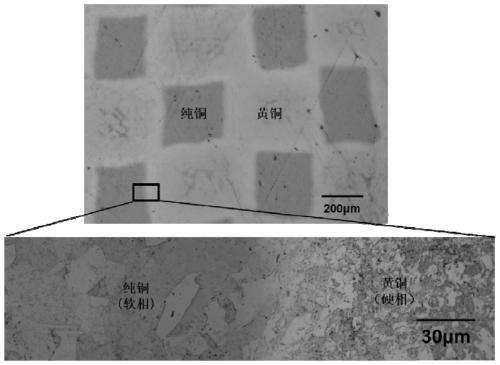

[0034] The thickness of the pure copper and brass plates used in this embodiment is 1mm, and the size is 50×100mm 2 , the chemical composition (wt.%) of pure copper used is: Cu: 99.94, Zn: 0.0041, Pb: 0.0007, Sn: 0.0005, Fe: 0.0031, Ni: 0.0028, Si: 0.028, and the rest are unavoidable impurities , The chemical composition (wt.%) of brass is: Cu: 63.25, Zn: 36.42, Fe: 0.025, Pb: 0.0005, Sb: 0.002, Bi: 0.0005, P: 0.004, and the rest are unavoidable impurities.

[0035] Select 25 pieces of pure copper and brass plates, firstly perform mechanical grinding and cleaning on the upper and lower surfaces, remove the surface oxide layer, an...

Embodiment 2

[0045] This embodiment adopts the following equipment: high-temperature diffusion pressure welding equipment, rotary forging equipment, and tube furnace for heat treatment.

[0046] The process flow chart for preparing a pure copper-brass composite wire with a soft / hard filamentary structure in this embodiment is as followsfigure 1 As shown, the specific operation is as follows:

[0047] The thickness of the pure copper and brass plates used in this embodiment is 1mm, and the size is 40×80mm 2 , the chemical composition (wt.%) of pure copper used is: Cu: 99.94, Zn: 0.0041, Pb: 0.0007, Sn: 0.0005, Fe: 0.0031, Ni: 0.0028, Si: 0.028, and the rest are unavoidable impurities , The chemical composition (wt.%) of brass is: Cu: 63.25, Zn: 36.42, Fe: 0.025, Pb: 0.0005, Sb: 0.002, Bi: 0.0005, P: 0.004, and the rest are unavoidable impurities. Select 20 pieces of pure copper and brass plates, firstly perform mechanical grinding and cleaning on the upper and lower surfaces, remove the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap