A kind of Cu-doped SNSE semiconductor thin film and electrochemical preparation method thereof

A semiconductor and electrochemical technology, applied in the field of Cu-doped SnSe semiconductor thin film and its electrochemical preparation, can solve problems such as limitations, achieve the effect of avoiding cracks and holes, suitable for large-scale industrial production, and high carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

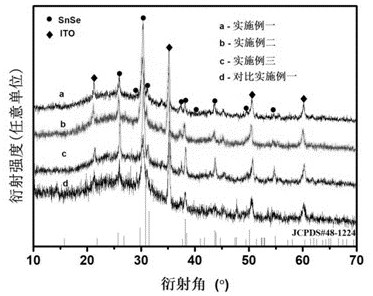

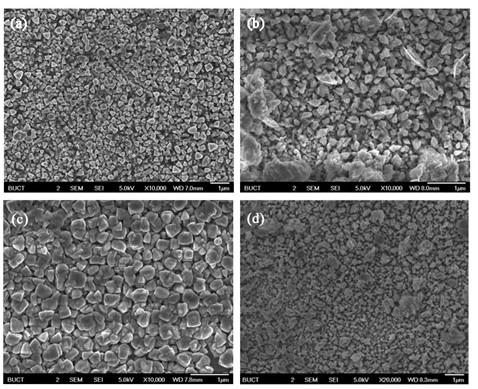

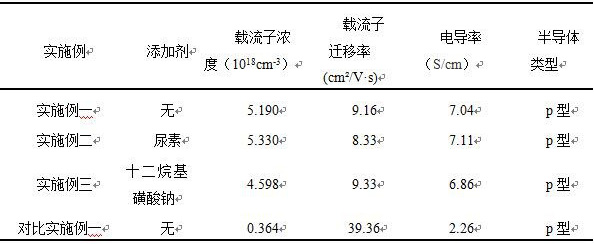

Embodiment 1

[0040] (1) Preparation of electrodeposition solution: Weigh 0.90g of disodium EDTA, 0.45g of SnCl in turn 2 ·2H 2 O, 0.13g Na 2 SeO 3 ·5H 2 O, CuCl 2 ·5H 2 O, dissolve it in 200ml of deionized water after deaeration, stir evenly, and adjust the pH to 2.6 with 0.1M dilute hydrochloric acid.

[0041] (2) Electrodeposition: the solution prepared in step (1) is used as the electrolyte, the pretreated ITO glass is used as the working electrode, the saturated calomel electrode is used as the reference electrode, and the platinum sheet is used as the auxiliary electrode. Connect it to the corresponding terminal button of the potentiostat, ensure that the distance between the working electrode and the platinum plate is 3cm, and ensure that the temperature of the electrolyte is between 15°C and 40°C, and the deposition time is 20min-60min to obtain Cu-doped SnSe The pre-deposited film was used to test the chemical composition of the film with an Oxford INCA-Penta-FET-X3 X-ray ene...

Embodiment 2

[0044] (1) Preparation of electrodeposition solution: Weigh 0.90g of disodium EDTA, 0.45g of SnCl in turn 2 ·2H 2 O, 0.13g Na 2 SeO 3 ·5H 2 O, CuCl 2 ·5H 2 O, the addition amount of urea is 10mg / L, it is dissolved in 200ml of deionized water after deaeration and evenly stirred, and the pH is adjusted to 2.6 with 0.1M dilute hydrochloric acid.

[0045] (2) Electrodeposition: the solution prepared in step (1) is used as the electrolyte, the pretreated ITO glass is used as the working electrode, the saturated calomel electrode is used as the reference electrode, and the platinum sheet is used as the auxiliary electrode. Connect it to the corresponding terminal button of the potentiostat, ensure that the distance between the working electrode and the platinum plate is 3cm, and ensure that the temperature of the electrolyte is between 15°C and 40°C, and the deposition time is 20min-60min to obtain Cu-doped SnSe The pre-deposited film was used to test the chemical composition ...

Embodiment 3

[0048] (1) Preparation of electrodeposition solution: Weigh 0.90g of disodium EDTA, 0.45g of SnCl in turn 2 ·2H 2 O, 0.13g Na 2 SeO 3 ·5H 2 O, CuCl 2 ·5H 2 O, the addition amount of sodium dodecyl sulfonate is 10mg / L, dissolve it in 200ml of deionized water after deoxygenation, stir evenly, and adjust the pH to 2.6 with 0.1M dilute hydrochloric acid.

[0049] (2) Electrodeposition: the solution prepared in step (1) is used as the electrolyte, the pretreated ITO glass is used as the working electrode, the saturated calomel electrode is used as the reference electrode, and the platinum sheet is used as the auxiliary electrode. Connect it to the corresponding terminal button of the potentiostat, ensure that the distance between the working electrode and the platinum plate is 3cm, and ensure that the temperature of the electrolyte is between 15°C and 40°C, and the deposition time is 20min-60min to obtain Cu-doped SnSe The pre-deposited film was used to test the chemical comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com