Environment-friendly spinning size and preparation method thereof

A kind of textile size, environmental protection technology, applied in the field of environment-friendly textile size and its preparation, can solve the problems of hard size film, environmental pollution, poor adhesion of synthetic fibers, etc., to achieve the improvement of viscosity stability, preparation and mixing Simple, effect of reducing weaving defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

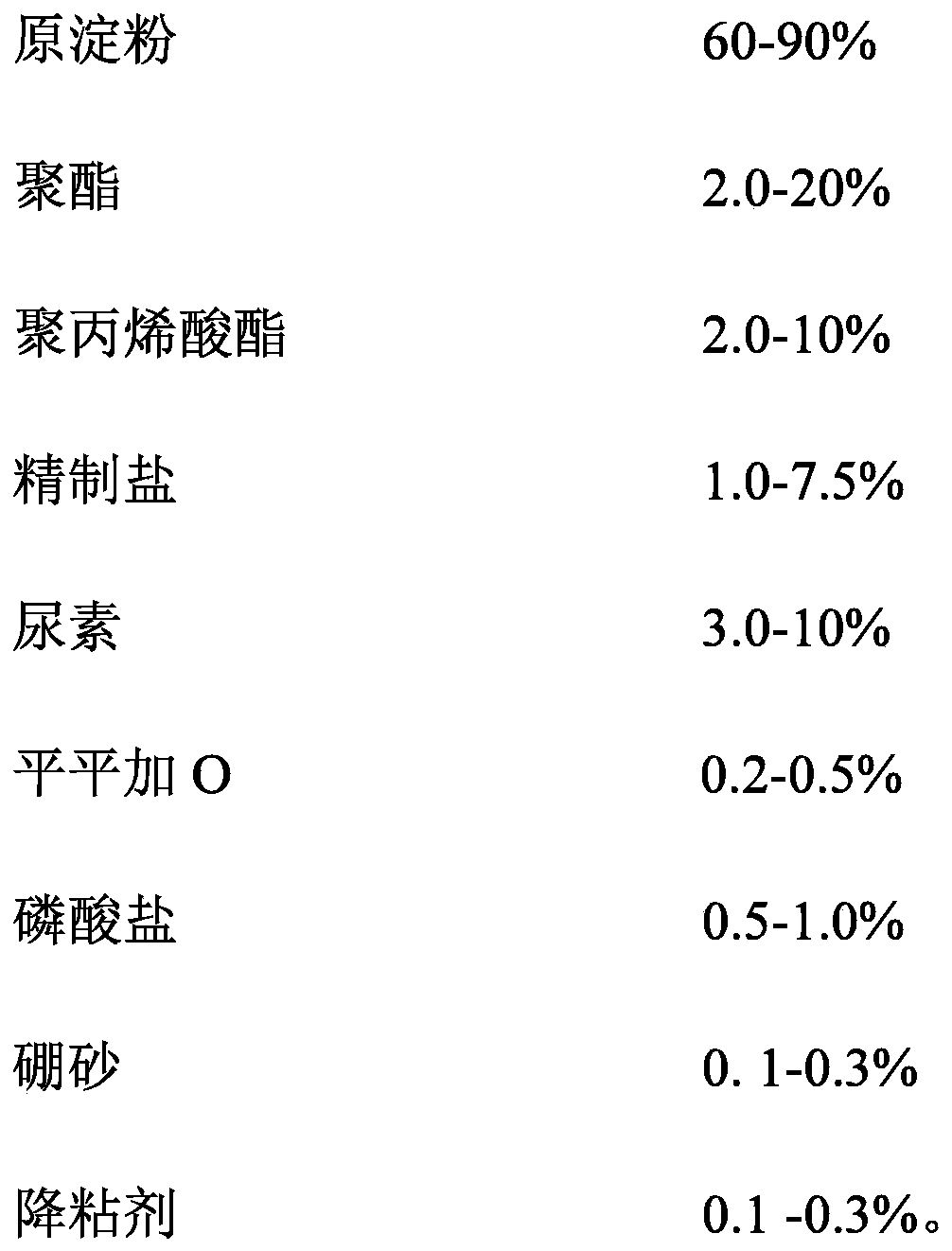

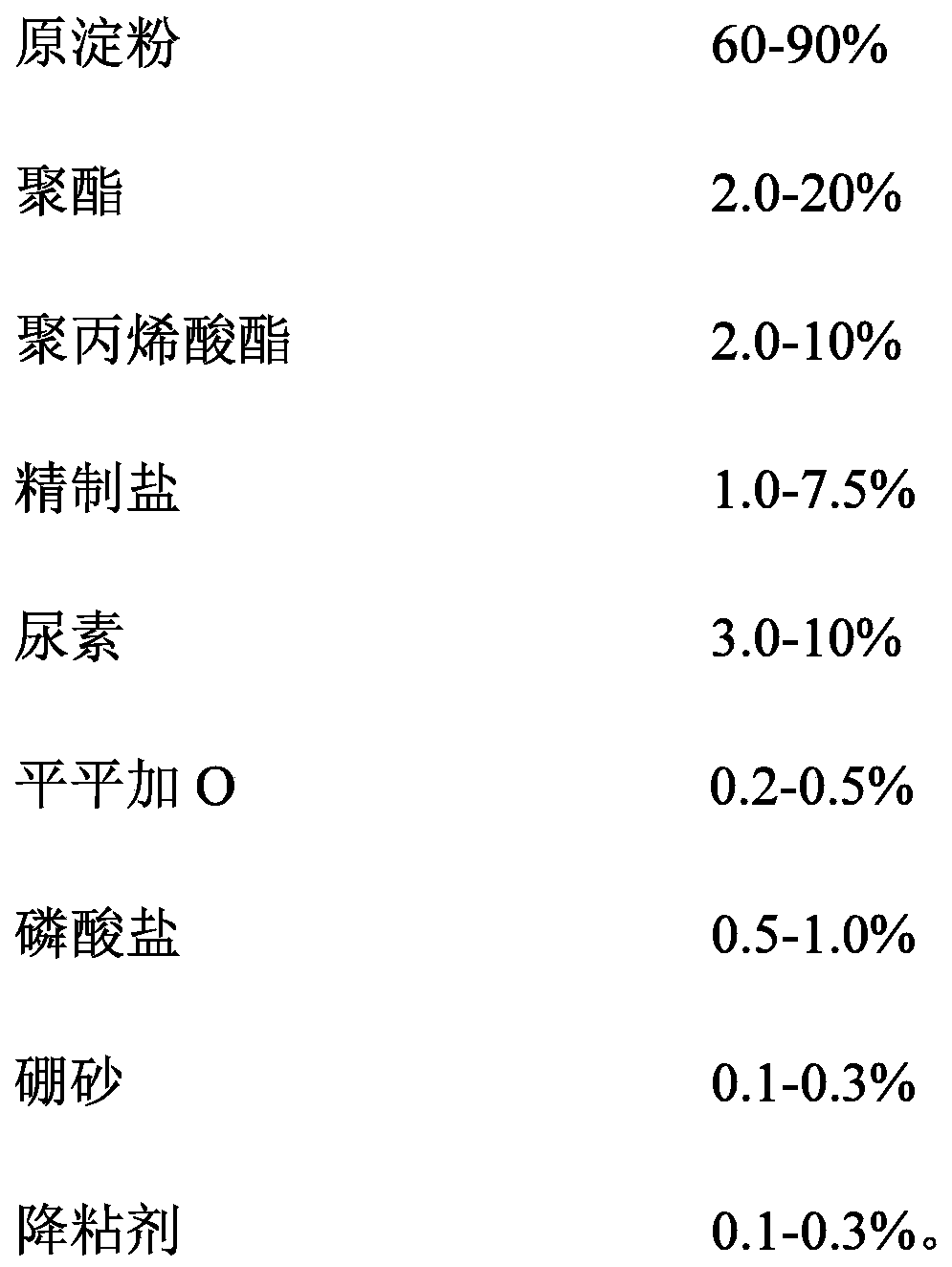

Embodiment 1

[0031] Put 20g water-soluble polyester slurry, 20g polyacrylate, 10g industrial refined salt, 39g urea, 4g flat plus O, 5g sodium tripolyphosphate, 1g borax and 1g sodium persulfate into the mixer at normal temperature, mix and stir After 5 minutes, the first mixture was obtained, and 900 g of cornstarch was added to the first mixture, and the stirring was continued for 5 minutes to obtain an environmentally friendly textile size.

Embodiment 2

[0033] Put 75g water-soluble polyester slurry, 50g polyacrylate, 37.5g industrial refined salt, 50g urea, 2g flat plus O, 5g trisodium phosphate, 3g borax and 0.5g ammonium persulfate into the mixing mixer at normal temperature, mix Stir for 10 minutes to obtain the first mixture, add 450 g of corn starch and 325 g of tapioca starch to the first mixture, and continue stirring for 10 minutes to obtain an environmentally friendly textile slurry.

Embodiment 3

[0035] Put 107g water-soluble polyester slurry, 100g polyacrylate, 75g industrial refined salt, 100g urea, 5g flat plus O, 5g sodium tripolyphosphate and 5g trisodium phosphate, 2g borax and 0.5g into the mixing mixer at room temperature Potassium persulfate was mixed and stirred for 5 minutes to obtain the first mixture, 250 g of corn starch and 400 g of potato starch were added to the first mixture, and the stirring was continued for 10 minutes to obtain an environmentally friendly textile slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com