A heat treatment waste gas combustion purification and waste heat recovery device

A waste heat recovery device and waste gas combustion technology, applied in waste heat treatment, lighting and heating equipment, furnaces, etc., can solve the problems of polluted air, ineffective use of heat energy, and inability to purify high-temperature waste gas in time, and achieve good safety and ease of use. The effect of easy maintenance, installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

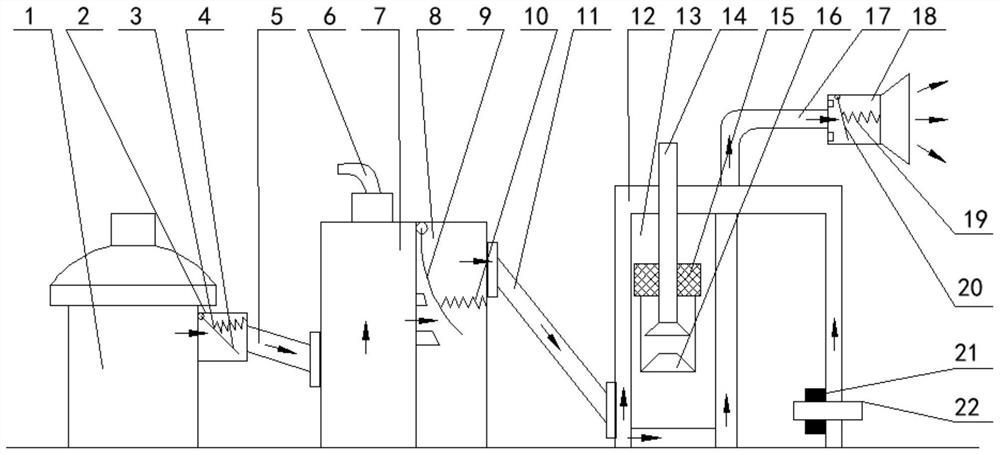

[0015] figure 1 Among them, a heat treatment waste gas combustion purification and waste heat recovery device, including a heat treatment heating furnace 1 that generates high-temperature waste gas in the production process, the waste gas of the heat treatment heating furnace can overflow from the gas outlet above the heat treatment heating furnace body, and the gas outlet is hinged. There is an air outlet cover fixedly connected to the periphery of the air valve and the air outlet, and the air outlet is located in the air outlet cover. An air outlet spring is fixedly connected between the air outlet valve and the air outlet cover. Ensure that the high-temperature exhaust gas can enter the combustion chamber smoothly; a combustion air pipe is installed on the top of the combustion chamber, and the gas outlet of the combustion chamber is connected with the air collection chamber. In the air collection chamber, an arc door of the air collection chamber is hinged at the gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com