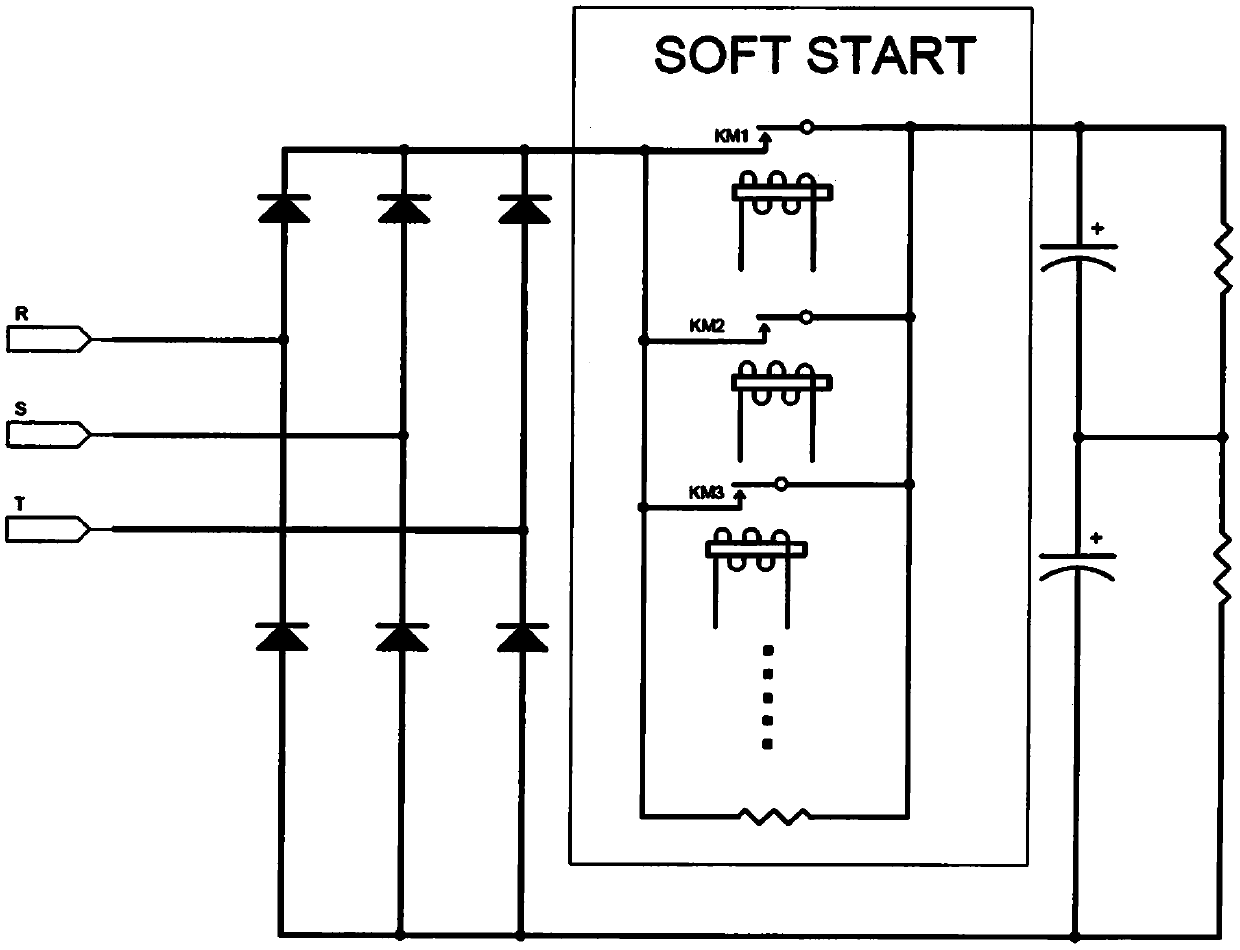

Drive circuit for soft-start contactor of frequency converter

A technology for driving circuits and contactors, applied in circuits, relays, electrical components, etc., can solve problems such as increasing the difficulty and cost of power supply design, electromagnetic interference, and affecting the normal operation of peripheral equipment, etc., to reduce the capacity of 24V power supply, 24V voltage The effect of the fluctuation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

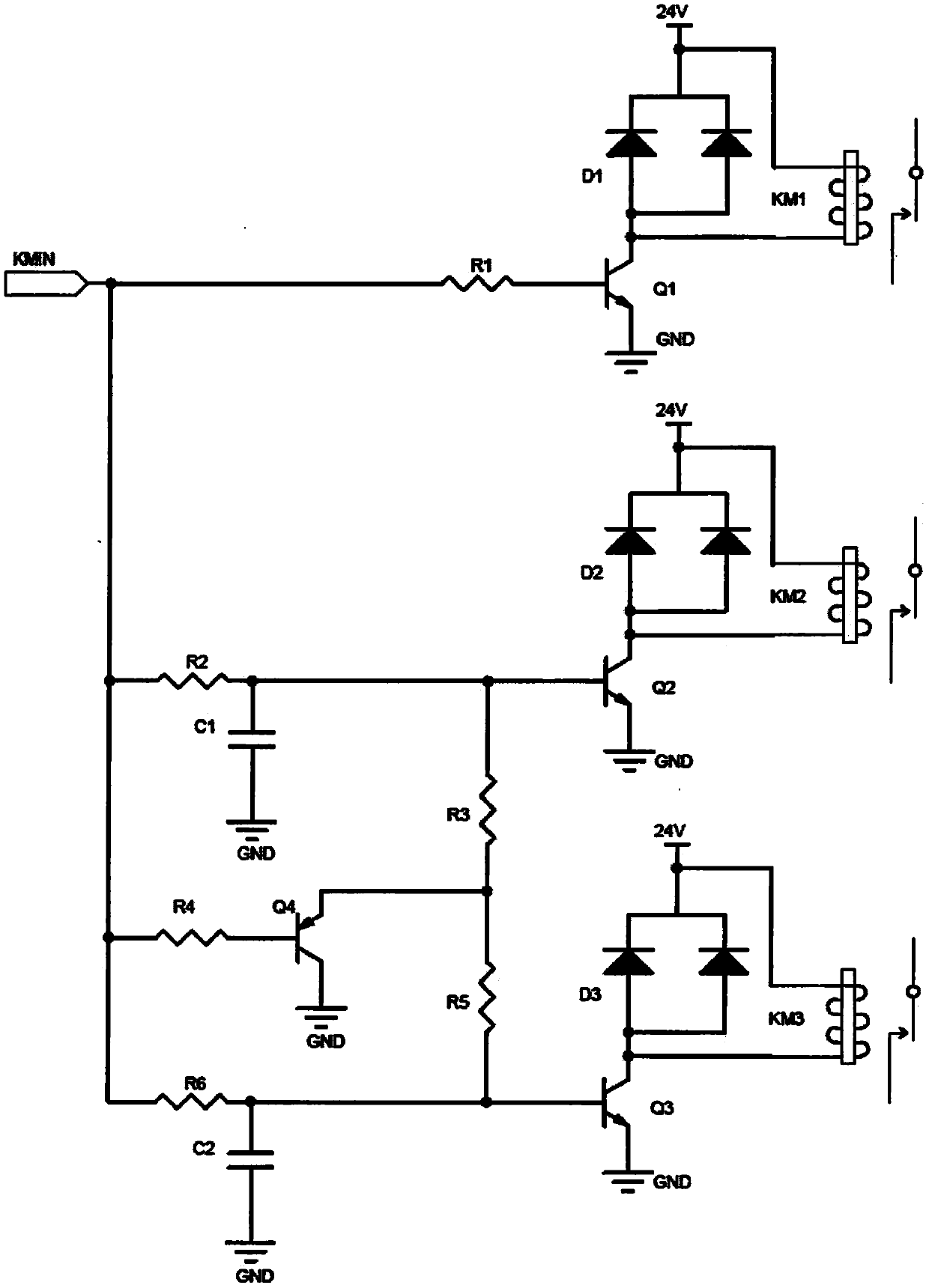

[0023] Such as figure 2 Shown is the first implementation example of the patent of the present invention.

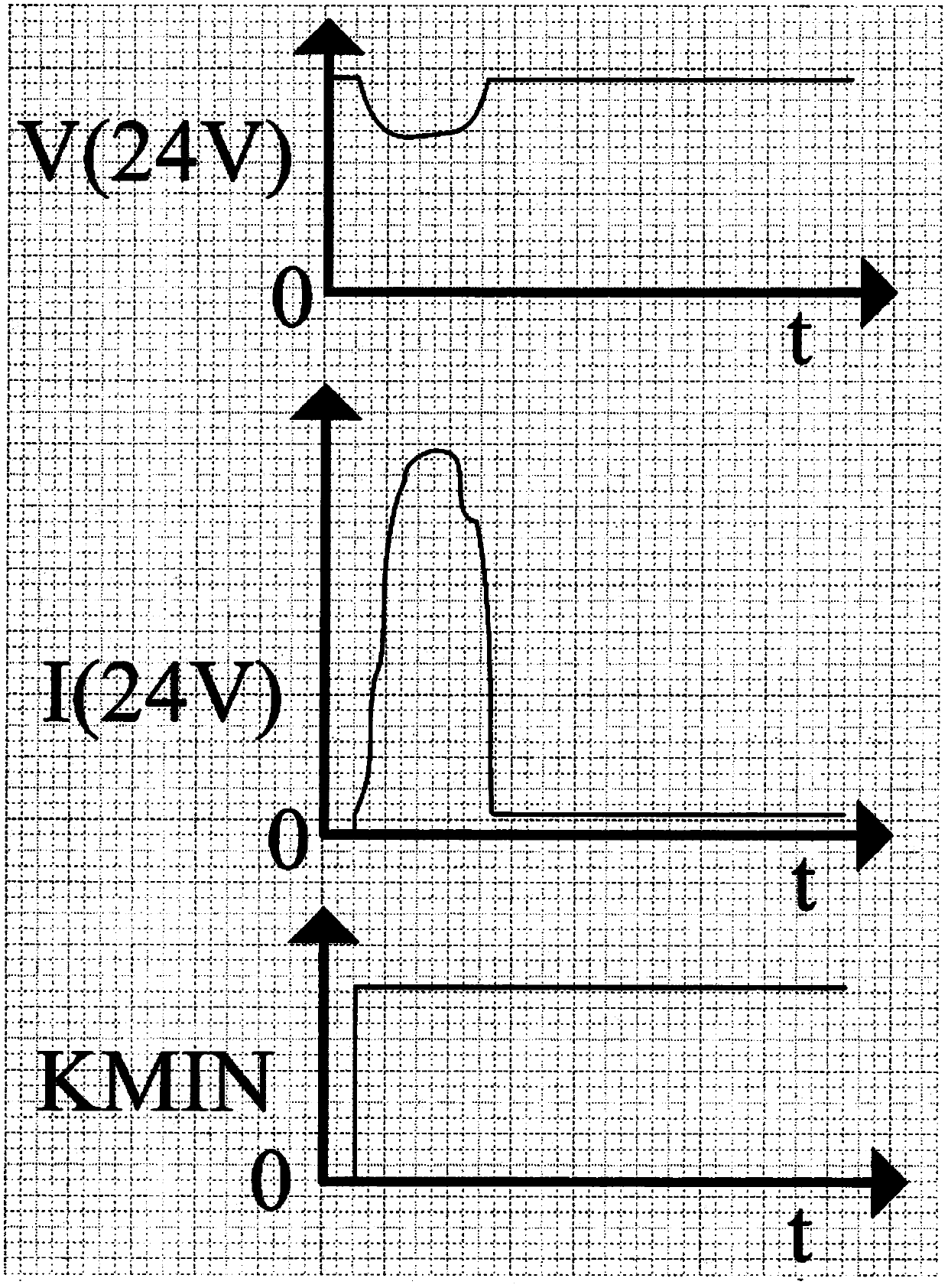

[0024] The contactor pick-up signal KMIN from the control system is connected to the base of the first triode Q1 through the first current limiting resistor R1, and the emitter of the first triode Q1 is connected to the contactor driving power ground GND, and the collector of Q1 The electrodes are connected to one end of the coil of the first contactor KM1, and the other end of the coil of the first contactor KM1 is connected to the positive terminal 24V of the contactor drive power supply. The first diode D1 is connected in parallel at the two ends of the coil of the first contactor KM1 to play the role of freewheeling. When the contactor pull-in signal KMIN signal is valid, that is, high level, Q1 will be turned on soon, the KM1 coil is energized, and KM1 pulls in. At the moment of KM1 pull-in current (mS level), the current absorbed by the KM1 coil from the 24V pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com