Adhesive mounting mechanism, full-automatic pole piece manufacturing machine and battery core winding equipment

A glue sticking mechanism and pole piece technology, applied to circuits, electrical components, secondary batteries, etc., can solve the problems of inability to pull the tape, insufficient downforce, unstable tape adhesion, etc., and achieve easy accurate positioning and simple structure. , the effect of making up for the gap in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

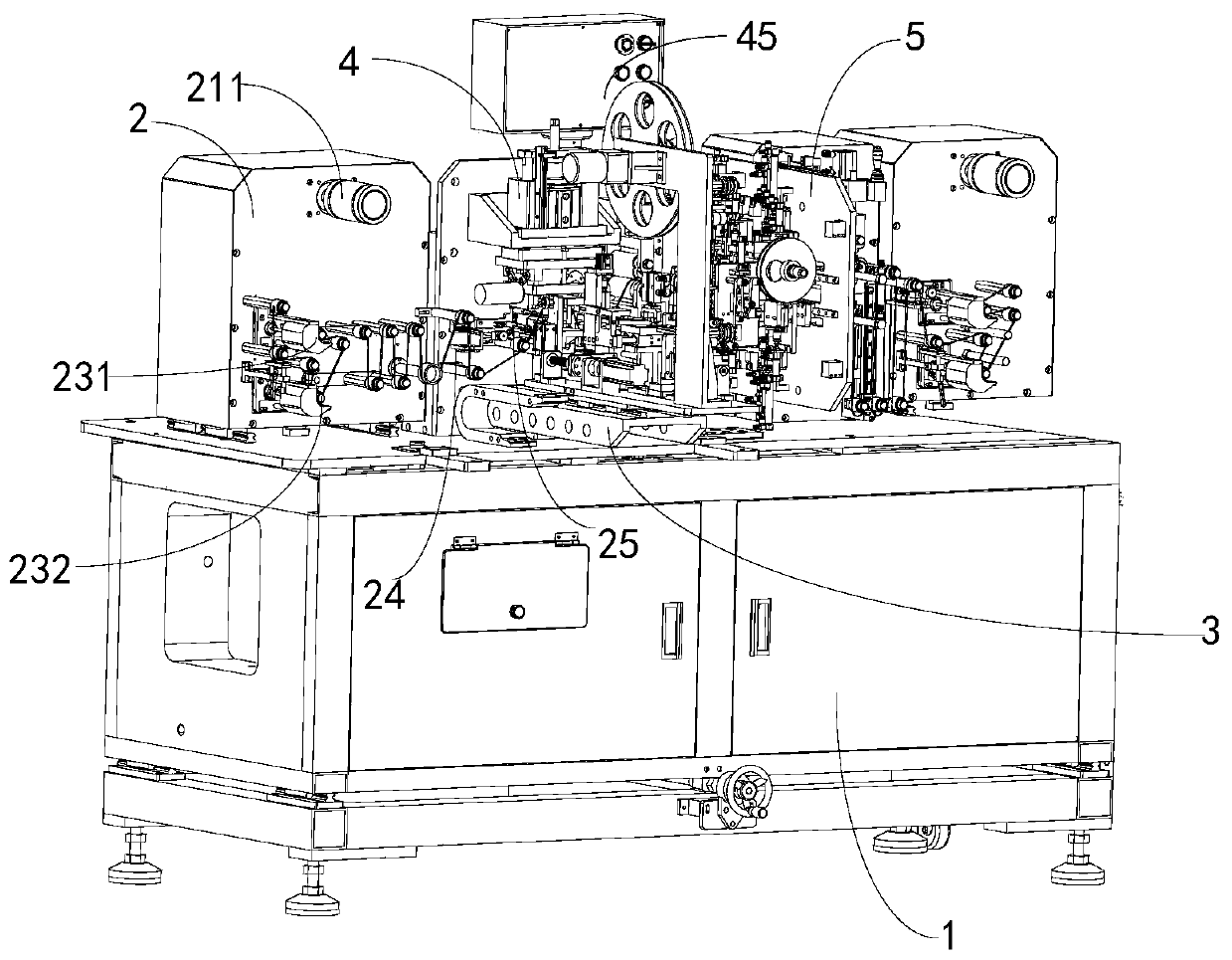

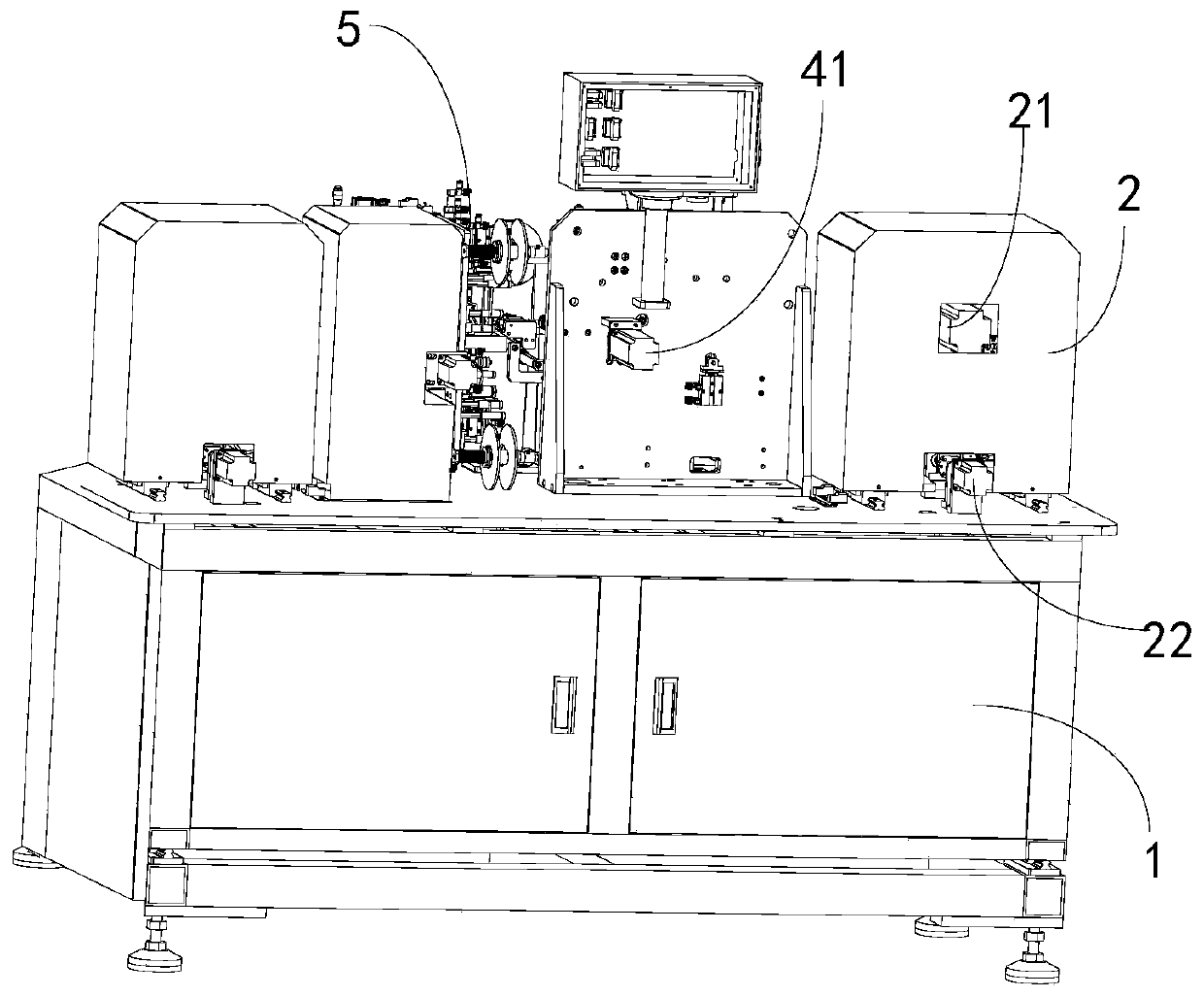

[0049] Please also refer to Figure 3 to Figure 5 , the fully automatic pole piece production machine of this embodiment includes a machine 1, a pole piece storage device 2, a pole lug wrapping device 3, a welding device 4 and a glue application mechanism 5. The pole piece pulling mechanism pulls the pole piece through the welding device and the gluing mechanism from the pole piece storage device.

[0050] The pole piece storage device 2 includes a pole piece shaft motor 21, a dust removal motor 22, a first pole piece detector 24, a second pole piece detector 25, a pole piece material disc 211, a first dust removal brush 231 and a second dust removal brush 232.

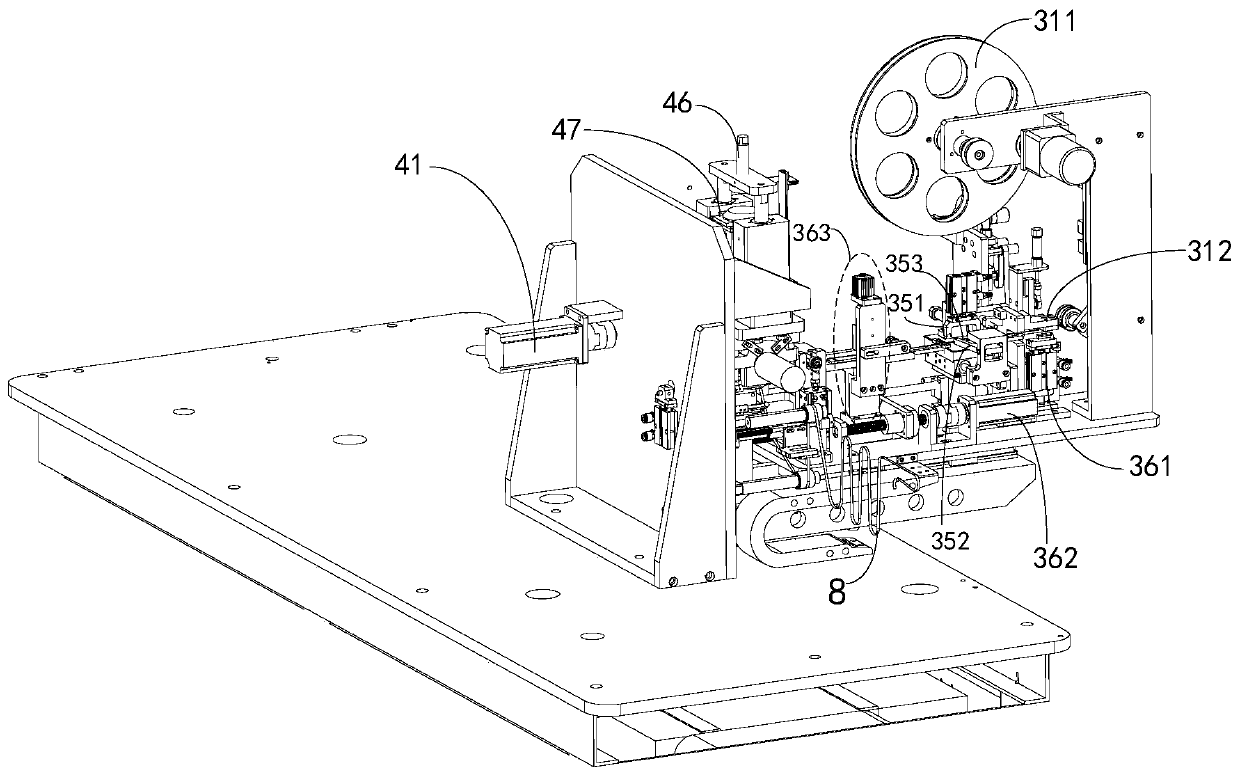

[0051] The encapsulating device includes a lug feeding mechanism 31 , a glue feeding mechanism 32 , a lug positioning mechanism 35 , a glue blowing mechanism 34 , a glue encapsulating mechanism 35 , a lug feeding mechanism 36 and a lug cutting mechanism 37 .

[0052] The tab feeding mechanism 31 includes a tab mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com