Package substrate and airtight package using same

A hermetic packaging and packaging technology, which is used in semiconductor/solid-state device parts, electrical components, electrical solid-state devices, etc., and can solve the problems of thermal degradation of internal components and high softening temperature of glass powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

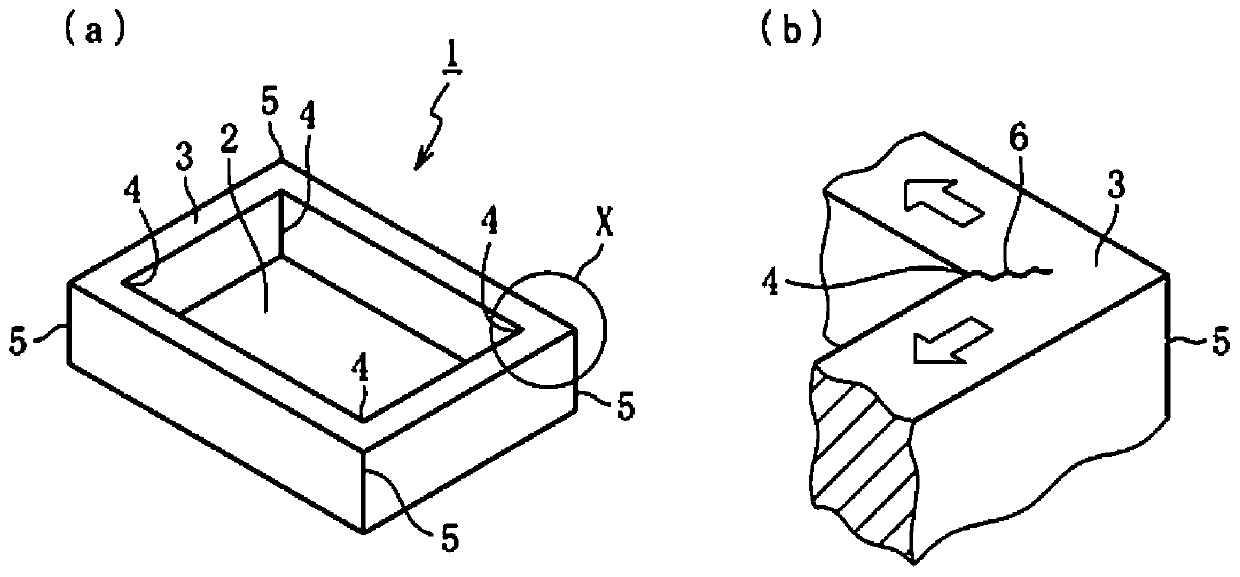

[0035] The package base of the present invention has a substantially rectangular base and a substantially frame-shaped frame provided along the outer periphery of the base. In this way, internal components such as sensor elements can be accommodated easily in the frame portion of the package base. In addition, the effective area for functioning as a device can be enlarged.

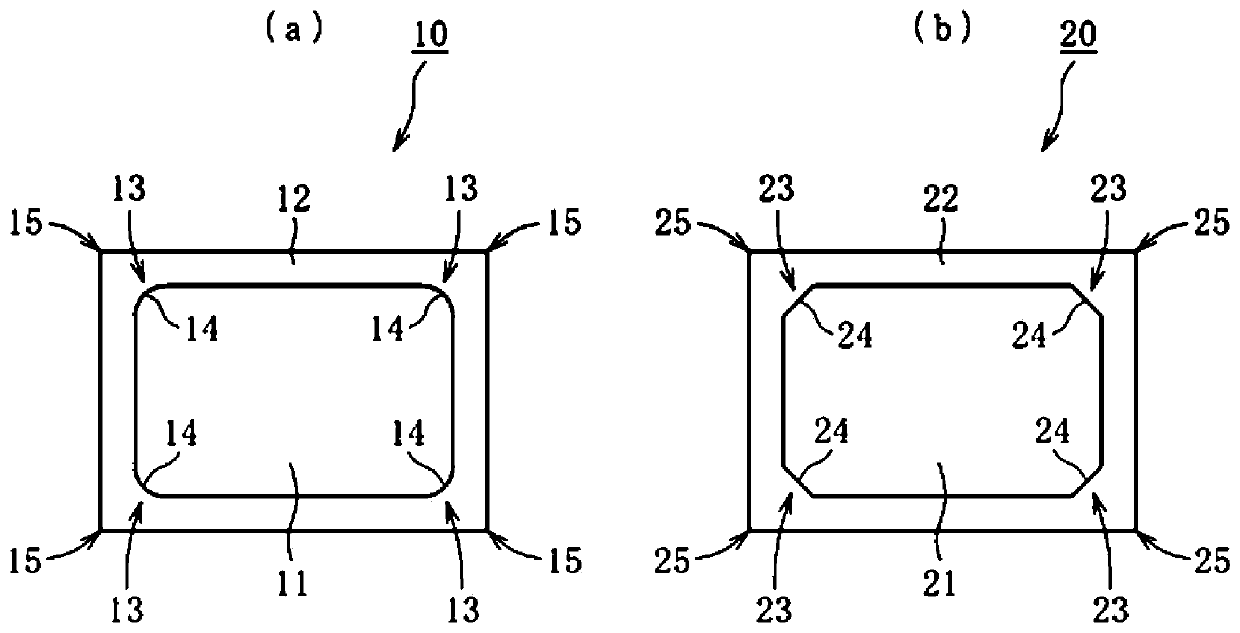

[0036] In the package base of the present invention, the stress buffering portion is provided at all or a part of the inner wall corners of the frame portion, and preferably, the stress buffering portion is provided at all the inner wall corners of the frame portion. In this way, deformation and cracks are less likely to occur in the package base after firing and sintering the precursor of the package base.

[0037]Preferably, the stress buffering portion is arc-shaped when viewed from the top side of the frame portion, and has an arc-shape with a curvature radius of 0.5 mm or more, 1.0 mm or more, partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com