Riser tensioning ring and pressure-bearing ring assembly welding method

A pressure ring and water riser technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult welding operation, poor welding quality, and low welding efficiency, so as to improve welding efficiency and reduce welding Difficulty, the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

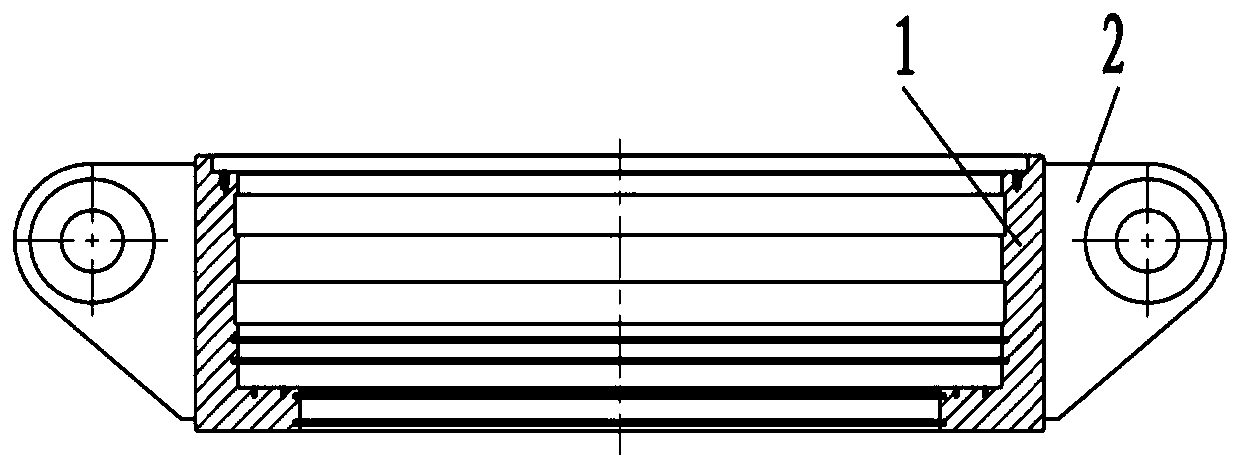

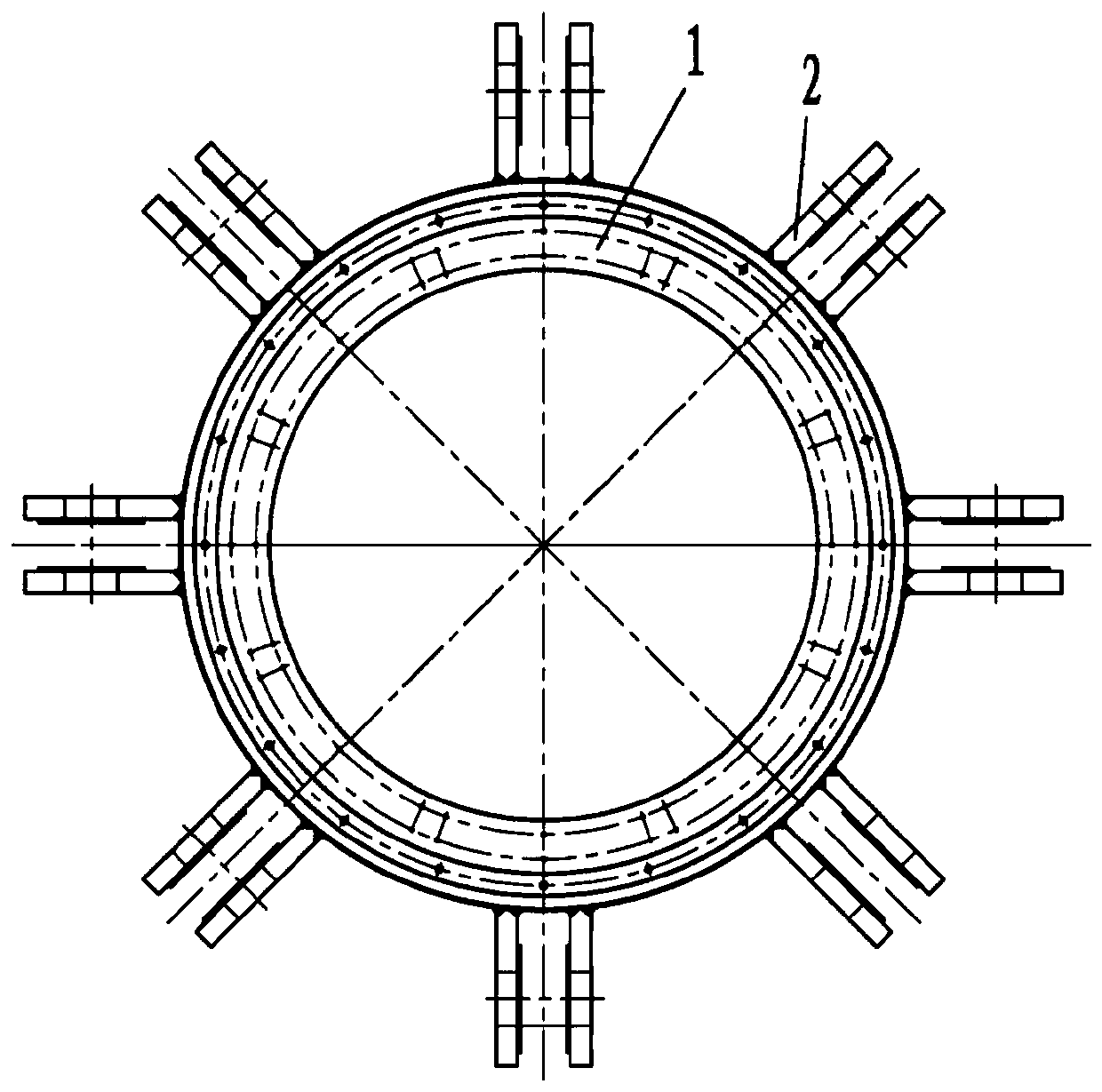

[0026] The present invention is a riser tension ring pressure bearing ring structure, such as figure 1 and figure 2 As shown, for cylinder body 1 and lug plate 2 including the pressure bearing ring, the inner diameter of cylinder body 1 and the pin hole of lug plate 2 are roughly machined respectively by conventional manufacturing methods to make auxiliary tooling, and then the cylinder body 1 and ear plate are completed by using the auxiliary tooling 2's full penetration welding, and finally processed as a whole.

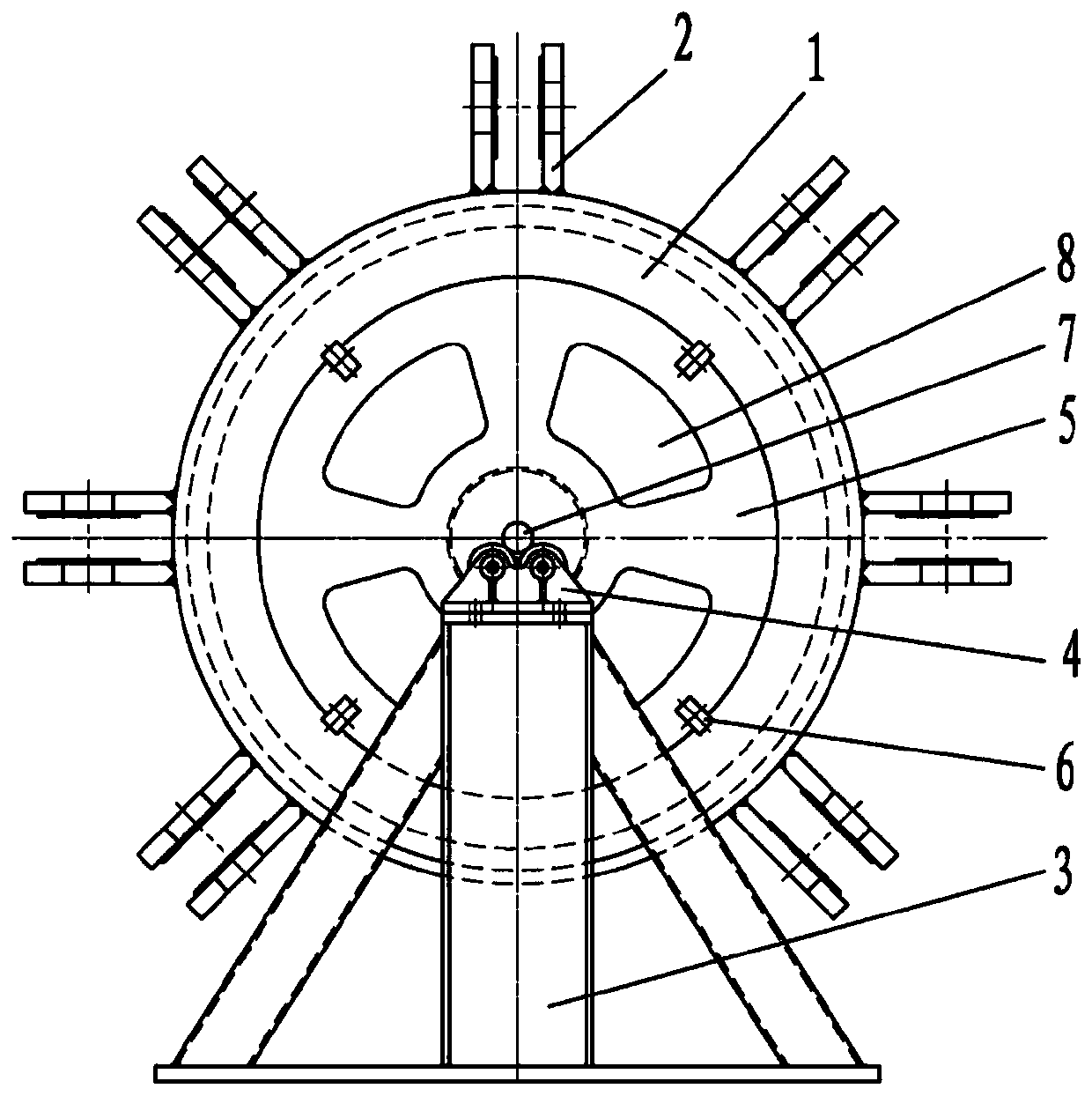

[0027] In this embodiment, both the cylinder body 1 and the lug plate 2 are X80J forgings, such as image 3 , Figure 4 As shown, the structure of the auxiliary tooling in this embodiment includes a tooling base 3, a tooling support plate 5 and a tooling shaft 7, the tooling base 3 adopts a U-shaped welding structure, and the top surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com