Rapid prototyping method of special-shaped quartz composite ceramic wave-transparent antenna window

A technology of composite ceramics and molding methods, which is applied in the direction of the radiation unit cover, etc., can solve the problems of high cost, long process cycle, and difficulty in imitation molding of special-shaped parts, etc., and achieve high molding efficiency, low process cost, and strong designability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

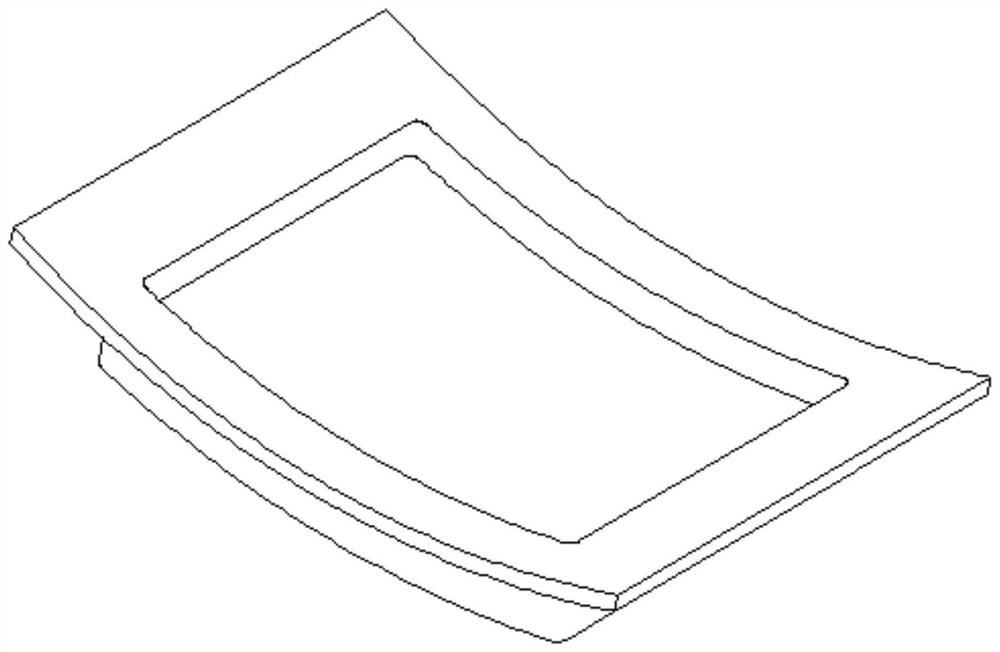

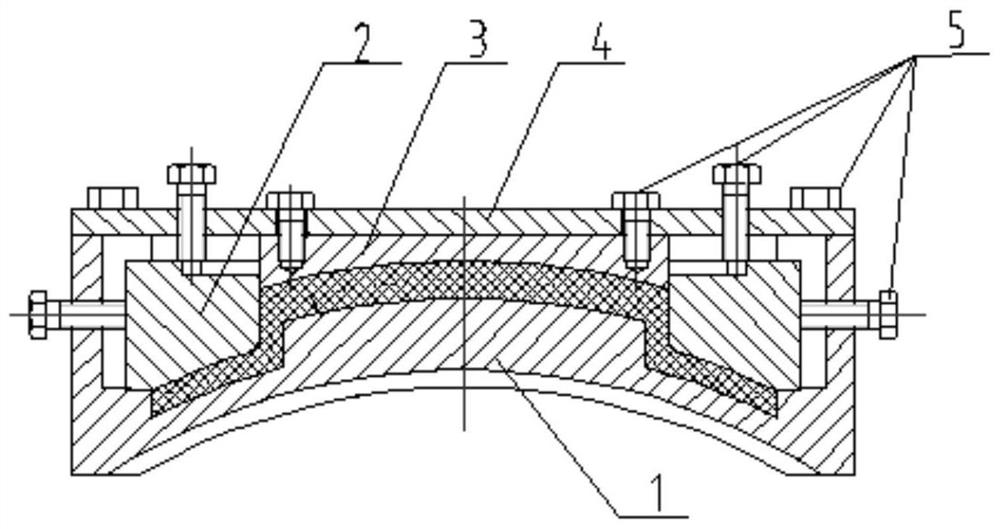

[0025] Embodiment, a special-shaped quartz composite ceramic wave-transparent antenna window rapid prototyping method, such as figure 1 and 2, the steps are as follows:

[0026] Step 1: Take 1kg of B-type quartz fiber cloth (satin cloth, 0.28mm, no twist), spread it on the upper layer of the water bath kettle, steam it for 15 hours, then dry it at 100°C for 3 hours, put it in a heat treatment furnace, and Oxygen heat treatment to remove sizing agent;

[0027] Step 2: Soak the pretreated quartz fiber cloth in 10% silica sol (more than 80% of the colloidal particles with a particle size below 100mm) for 1.5h, then let it air at room temperature for 15h, and then dry it at 120°C. Then cut or equivalent area size at 20mm 2 ~50mm 2 fiber cloth.

[0028] Step 3: Soak the fiber cloth in silica sol with a solid content of 65% for 1h to 2h, spread the dippe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com