A kind of preparation method of rubber accelerator diethyldithiocarbamate selenium

A technology of diethyldithiocarbamic acid and rubber accelerator, applied in the direction of organic chemistry, etc., to achieve the effects of simple operation, avoidance of waste water and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

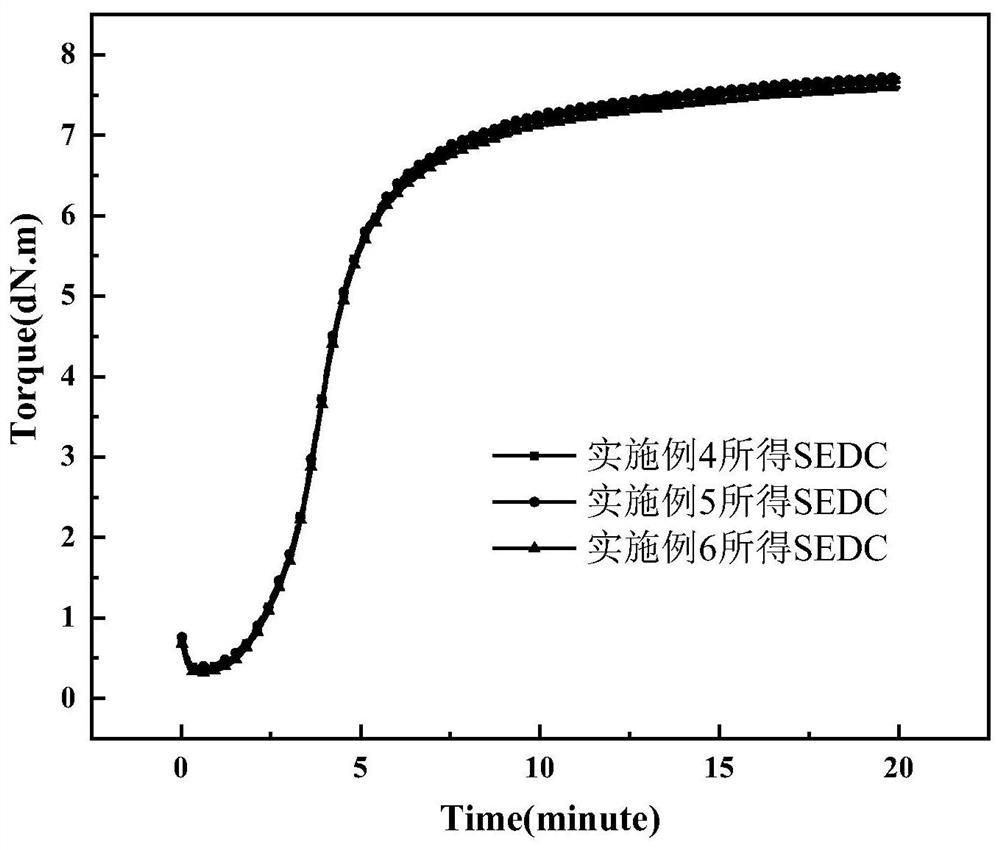

Embodiment 1

[0038] Dissolve 5.548g of selenium oxide (0.05mol) in 100mL of absolute ethanol under 300rpm stirring condition, then add 20.56mL of diethylamine (0.2mol), control the reaction temperature at 8°C, and stir for 20min to obtain solution A; Mix mL of carbon disulfide (0.2mol) with 13 mL of ethylene glycol, stir to make it evenly mixed to obtain a mixture, add 25.06 mL of the mixture dropwise to 120.56 mL of solution A, and keep warm for 2 hours after the addition; The rubber accelerator selenium diethyldithiocarbamate is obtained by drying, pulverizing and sieving. The yield of the obtained product is 89.5%, the melting point of the product is 111°C, and the decomposition temperature is 193°C.

Embodiment 2

[0040] Dissolve 5.548g of selenium oxide (0.05mol) in 150mL of absolute ethanol under 300rpm stirring condition, then add 25.7mL of diethylamine (0.25mol), control the reaction temperature at 8°C, stir for 20min to obtain solution A; Mix mL of carbon disulfide (0.25mol) with 16 mL of dimethyl sulfoxide, stir to make it evenly mixed to obtain a mixture, add 28.08 mL of the mixture dropwise to 175.7 mL of solution A, and keep warm for 2 hours after the addition; The rubber accelerator selenium diethyldithiocarbamate is obtained by filtering, drying, pulverizing and sieving. The yield of the obtained product is 91.3%, the melting point of the product is 113°C, and the decomposition temperature is 193°C.

Embodiment 3

[0042] Dissolve 5.548g of selenium oxide (0.05mol) in 150mL of absolute ethanol under 300rpm stirring condition, then add 30.84mL of diethylamine (0.3mol), control the reaction temperature at 8°C, and stir for 20min to obtain solution A; Mix mL of carbon disulfide (0.3mol) with 19 mL of ethyl acetate, stir to make it evenly mixed to obtain a mixture, add 31.09 mL of the mixture dropwise to 180.84 mL of solution A, and keep warm for 2 hours after the addition; The rubber accelerator selenium diethyldithiocarbamate is obtained by drying, pulverizing and sieving. The yield of the obtained product is 88.4%, the melting point of the product is 112°C, and the decomposition temperature is 192°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com