Diagnostic control method and system based on water level data process of water collecting well, storage medium and terminal

A diagnostic control and water collection well technology, which is applied in the general control system, control/regulation system, liquid level control, etc., can solve the problems of automatic control system influence, inaccurate overall data, etc., achieve autonomous control, avoid control failure, and realize The effect of self-learning and self-improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment discloses a diagnostic control method based on the water level data process of the water collection well, so that when the data is abnormal at the data collection end, the overall data is analyzed before the corresponding start and stop operation is performed on the water level of the water collection well, avoiding the entire automatic control. system has an impact.

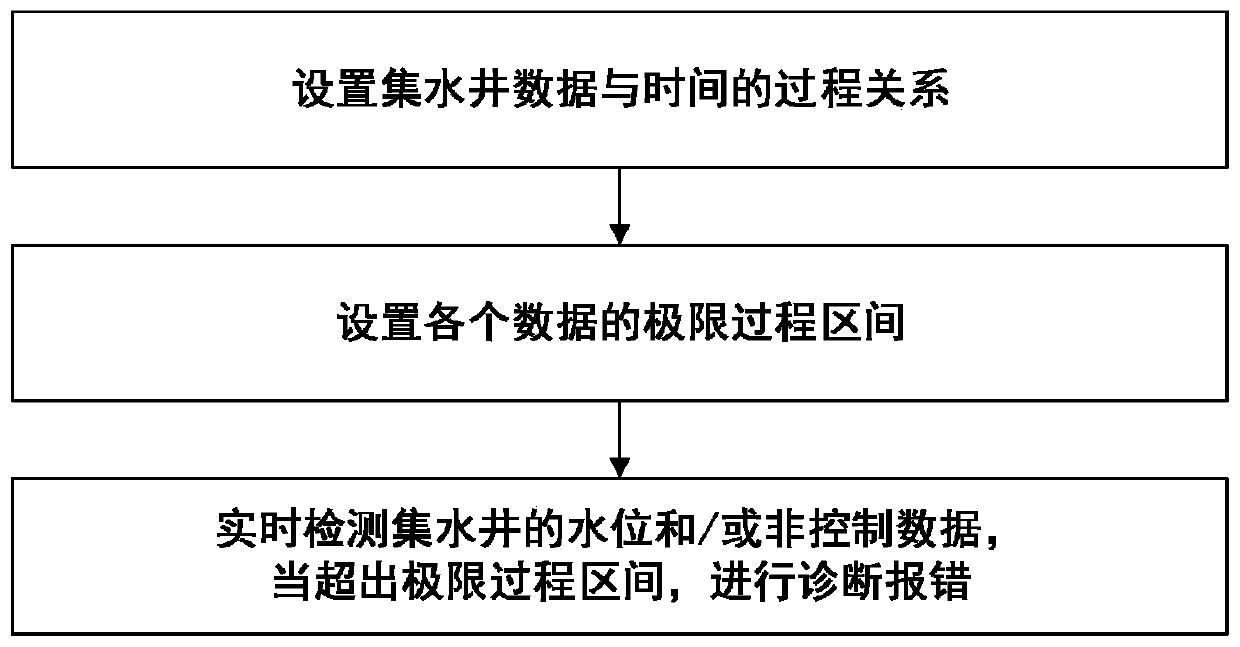

[0055] Specifically, this embodiment takes a water collection well as an example for illustration, as figure 1 As shown, the diagnostic control method based on the water level data process of the water collection well includes the following steps:

[0056] S1: Set the process relationship between water collection well data and time, the data includes control data and at least one non-control data associated with the control data; the control data is water level, and the non-control data includes water level rising / falling speed, One or more of the water volume of the water collection well...

Embodiment 2

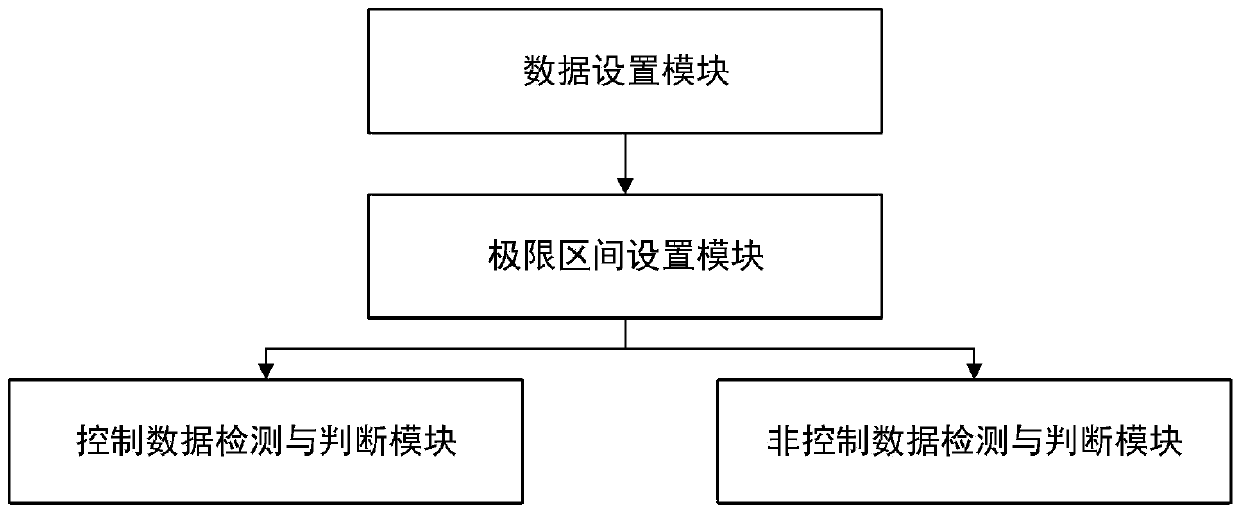

[0103] This embodiment also provides a diagnostic control system based on the water level data process of the water collection well. The inventive concept of this system is the same as that of Embodiment 1, so that when the data is abnormal at the data collection end, the overall data is analyzed before the water level of the corresponding water collection well is correspondingly analyzed. Start and stop operations to avoid impact on the entire automation control system. Specifically, such as figure 2 As shown, a diagnostic control system based on the water level data process of the water collection well includes:

[0104] Data setting module: used to set the process relationship between water collection well data and time, the data includes control data and at least one non-control data associated with the control data; the control data is water level, and the non-control data includes water level rise One or more of the descending speed, the water volume of the sump well, ...

Embodiment 3

[0121] Based on the realization of Embodiment 1, this embodiment also provides a storage medium on which computer instructions are stored, and when the computer instructions are run, the steps of the diagnostic control method based on the water level data process of the water collection well described in Embodiment 1 are executed. .

[0122] Based on this understanding, the technical solution of this embodiment is essentially or the part that contributes to the prior art or the part of the technical solution can be embodied in the form of a software product, and the computer software product is stored in a storage medium. Several instructions are included to make a computer device (which may be a personal computer, server, or network device, etc.) execute all or part of the steps of the method described in each embodiment of the present invention. The aforementioned storage medium includes: U disk, mobile hard disk, read-only memory (Read-OnlyMemory, ROM), random-access memory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com