Based on reverse intermediary principle, positioning, identification and selection of non-splashing ginseng seed harvesting and separation vehicle

A technology for positioning and identifying ginseng seeds, which can be used in picking machines, harvesters, agricultural machinery and implements, etc., and can solve problems such as polluted soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of this patent will be described in further detail below in conjunction with the specific implementation. The technical features or connection relationships described in the present invention are not described in detail. They are all existing technologies adopted.

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

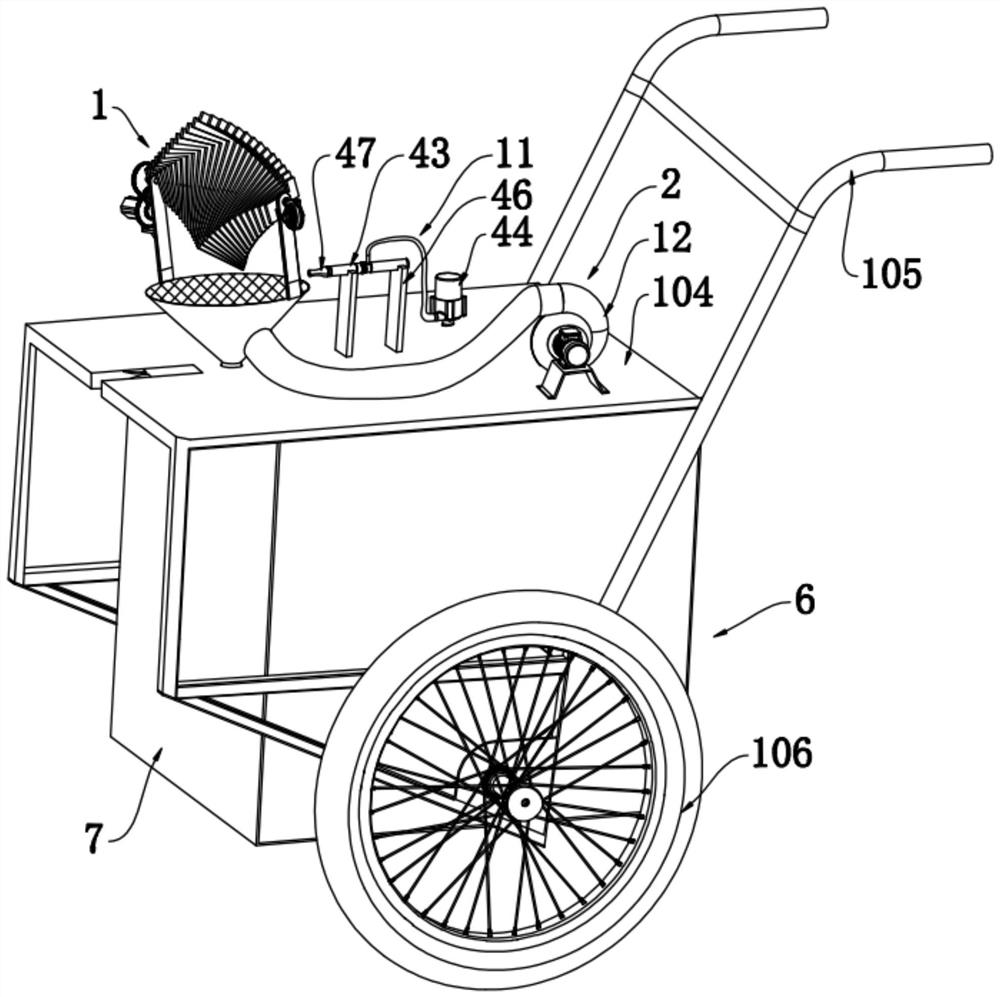

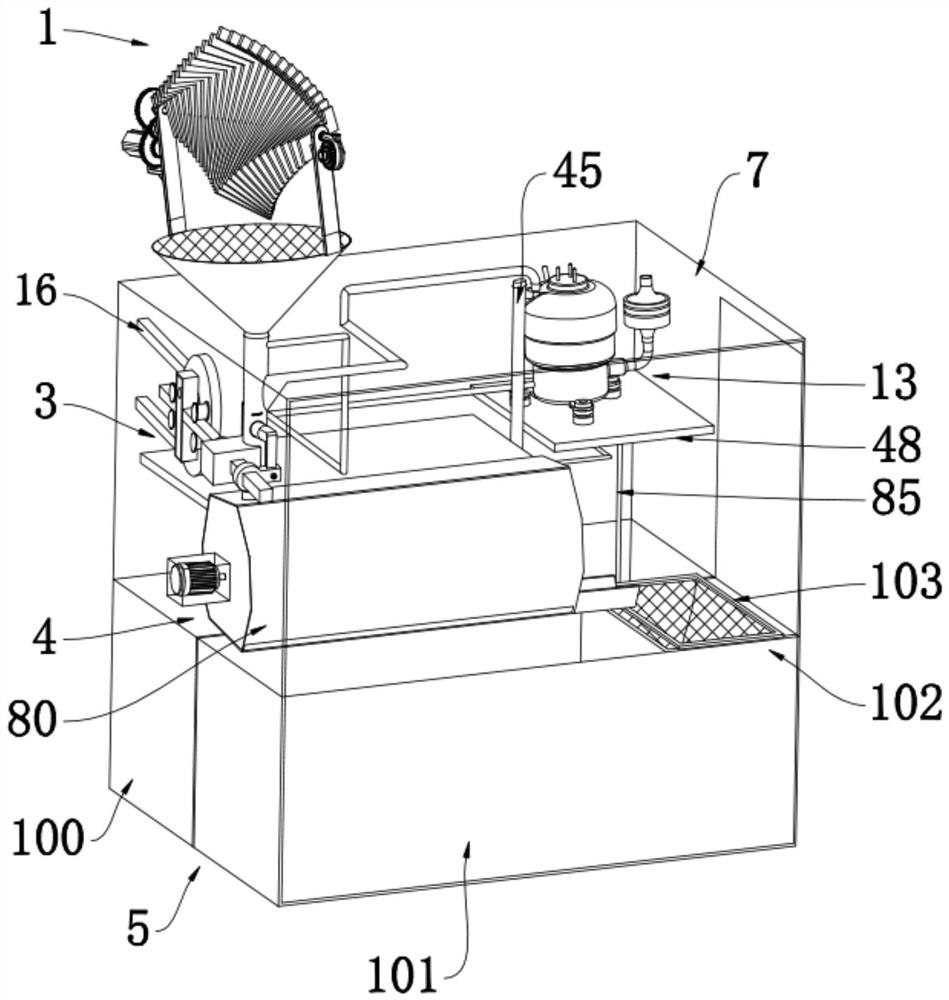

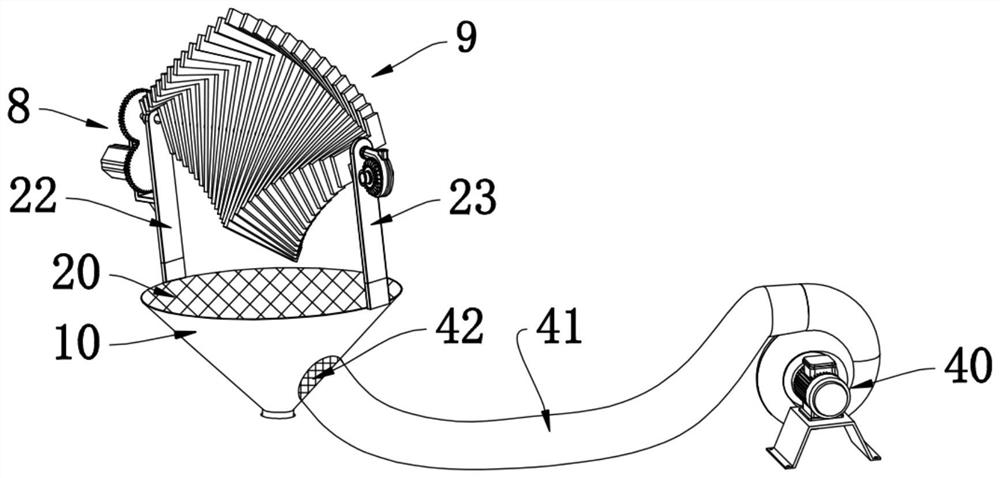

[0035] Such as Figure 1-19As shown, a non-splashing ginseng seed harvesting and separation vehicle based on the principle of reverse intermediary positioning, identification and selection, including an inflatable gathering, pulling, splitting, non-damage positioning, identification and selective harvesting mechanism 1, a reverse intermediary combined fruit gathering and freezing pretreatment mechanism 2. Sequential impact and slap type pulp crushing without splashing seed primary separation mechanism 3. Multi-directional laminating brush removal spray type pulp seed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com