Degradable sanitary napkin and preparation method thereof

A sanitary napkin and reverse osmosis technology, applied in the field of sanitary napkins, can solve the problems of non-degradable environmental pollution, unfavorable post-processing of sanitary napkins, non-degradable and other problems, and achieve the effect of excellent degradable performance, good moisture absorption rate, and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

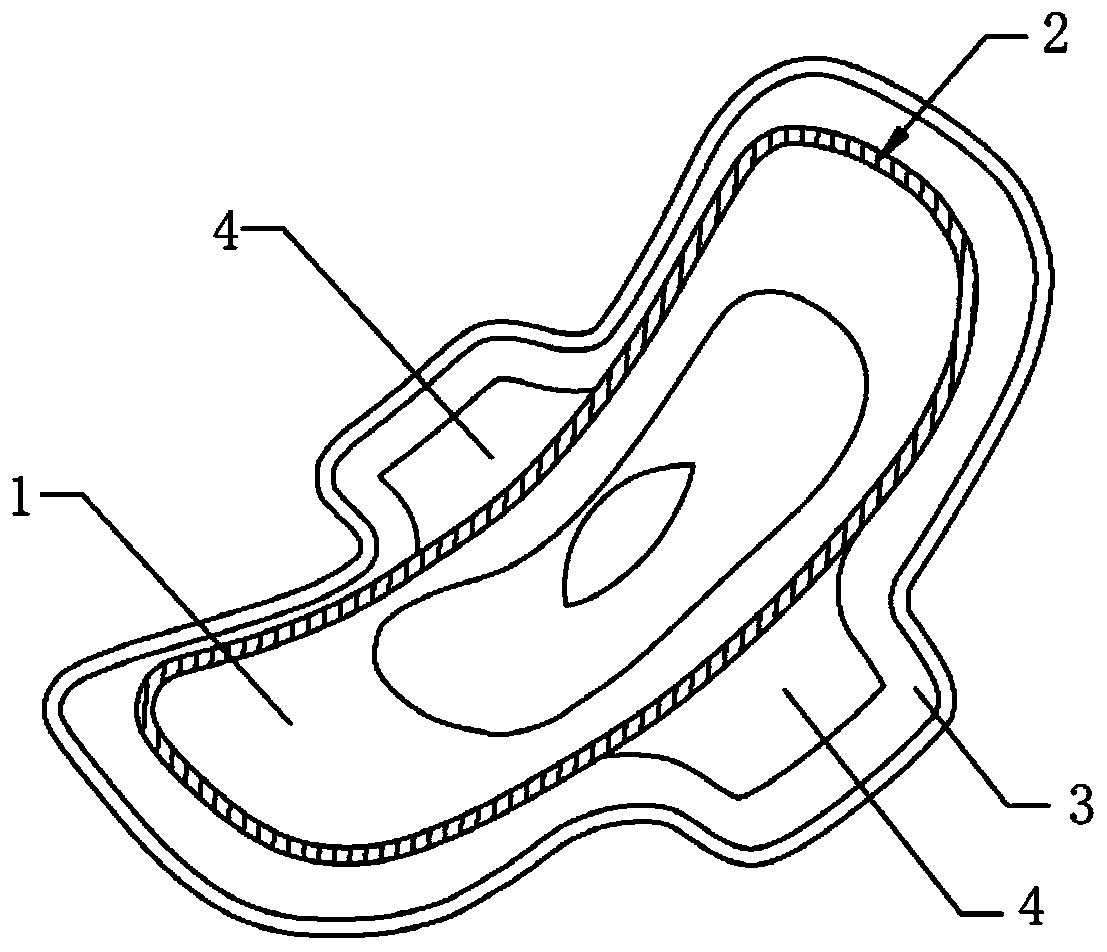

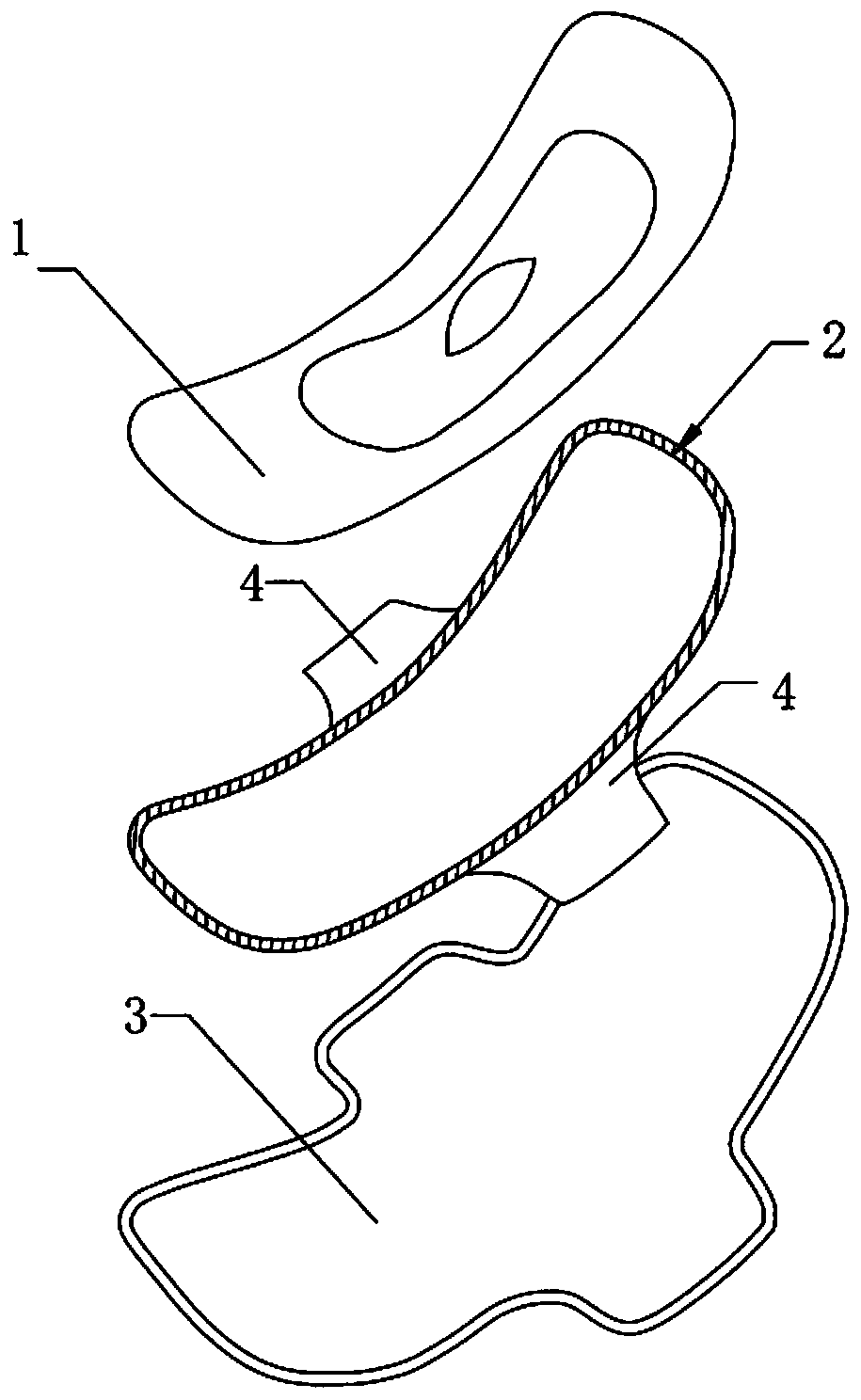

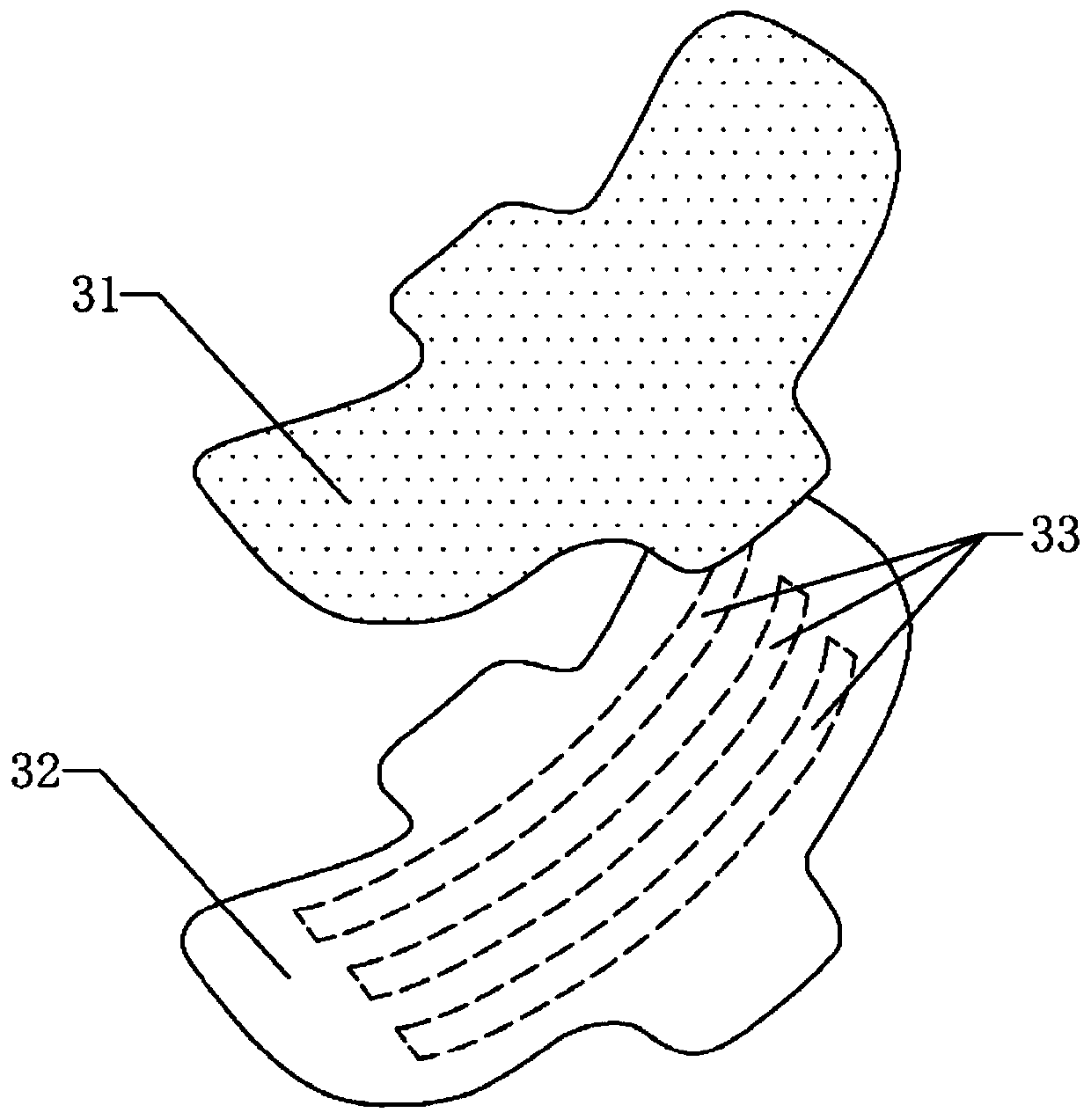

[0072] See Figure 1-4 , a degradable sanitary napkin, comprising a liquid-absorbent part 1, a leak-proof part 2, a waterproof bottom film 3 and two symmetrically arranged side wings 4, the liquid-absorbent part 1 includes water-soluble nonwoven fabrics arranged in sequence from top to bottom Cloth layer 11, water-soluble cotton layer 12, absorbent core layer 13 and reverse osmosis layer 14, the leak-proof member 2 extends outward from the surrounding edges of the reverse osmosis layer 14, and covers the water-soluble non-woven fabric layer 11 , the water-soluble cotton layer 12, the edge of the absorbent core layer 13 and folded to the upper surface edge of the water-soluble non-woven fabric layer 11, the two side wings 4 are symmetrically arranged on both sides of the leak-proof member 2, and the waterproof bottom film 3 is arranged on the lower surface of the reverse osmosis layer 14 and the lower surfaces of the two side wings 4, and the lower surface of the waterproof bot...

Embodiment 2

[0077] The difference between this embodiment and above-mentioned embodiment 1 is:

[0078] The composite absorbent fiber includes the following raw materials in parts by weight:

[0079]

[0080]

[0081] Each part of said inorganic filler includes 2 parts of mica powder, 2 parts of calcium carbonate, 1 part of talcum powder and 0.5 part of cordierite powder; every part of said coupling agent includes 2 parts of 3-aminopropyltrimethoxysilane, 0.5 part of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 1.5 parts of γ-methacryloxypropyltrimethoxysilane and 2 parts of isopropyl dioleic acid acyloxy (dioctyl Phosphoryloxy) titanate; the solvent is a mixture of isopropanol, ethanol, ethyl acetate and water in a weight ratio of 0.5:2:1:3.

[0082] Described water-soluble modified PVA resin comprises the raw material of following weight portion:

[0083]

[0084] The modified nano powder is prepared by the following steps:

Embodiment 3

[0106] The difference between this embodiment and above-mentioned embodiment 1 is:

[0107] The composite absorbent fiber includes the following raw materials in parts by weight:

[0108]

[0109] Every part of said inorganic filler includes 3 parts of mica powder, 3 parts of calcium carbonate, 1.5 parts of talcum powder and 0.8 part of cordierite powder; Every part of said coupling agent includes 2.2 parts of 3-aminopropyltrimethoxysilane, 0.8 part γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 1.8 parts of γ-methacryloxypropyltrimethoxysilane and 2.5 parts of isopropyl dioleic acid acyloxy (dioctyl base phosphate acyloxy) titanate; the solvent is a mixture of isopropanol, ethanol, ethyl acetate and water in a weight ratio of 0.6:2.2:1:4.

[0110] Described water-soluble modified PVA resin comprises the raw material of following weight portion:

[0111]

[0112]

[0113] The modified nano powder is prepared by the following steps:

[0114] Step A, adding the titanate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com