g-C3N4-based composite photocatalytic material and preparation method thereof

A technology of composite photocatalysis and photocatalytic materials, which is applied in the field of g-C3N4/α-Fe2O3/RGO composite photocatalytic materials and its preparation, can solve the problems of low photocatalytic activity, short life, and poor light absorption ability, and achieve The effects of high degradation efficiency, inhibition of recombination, and enhanced photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

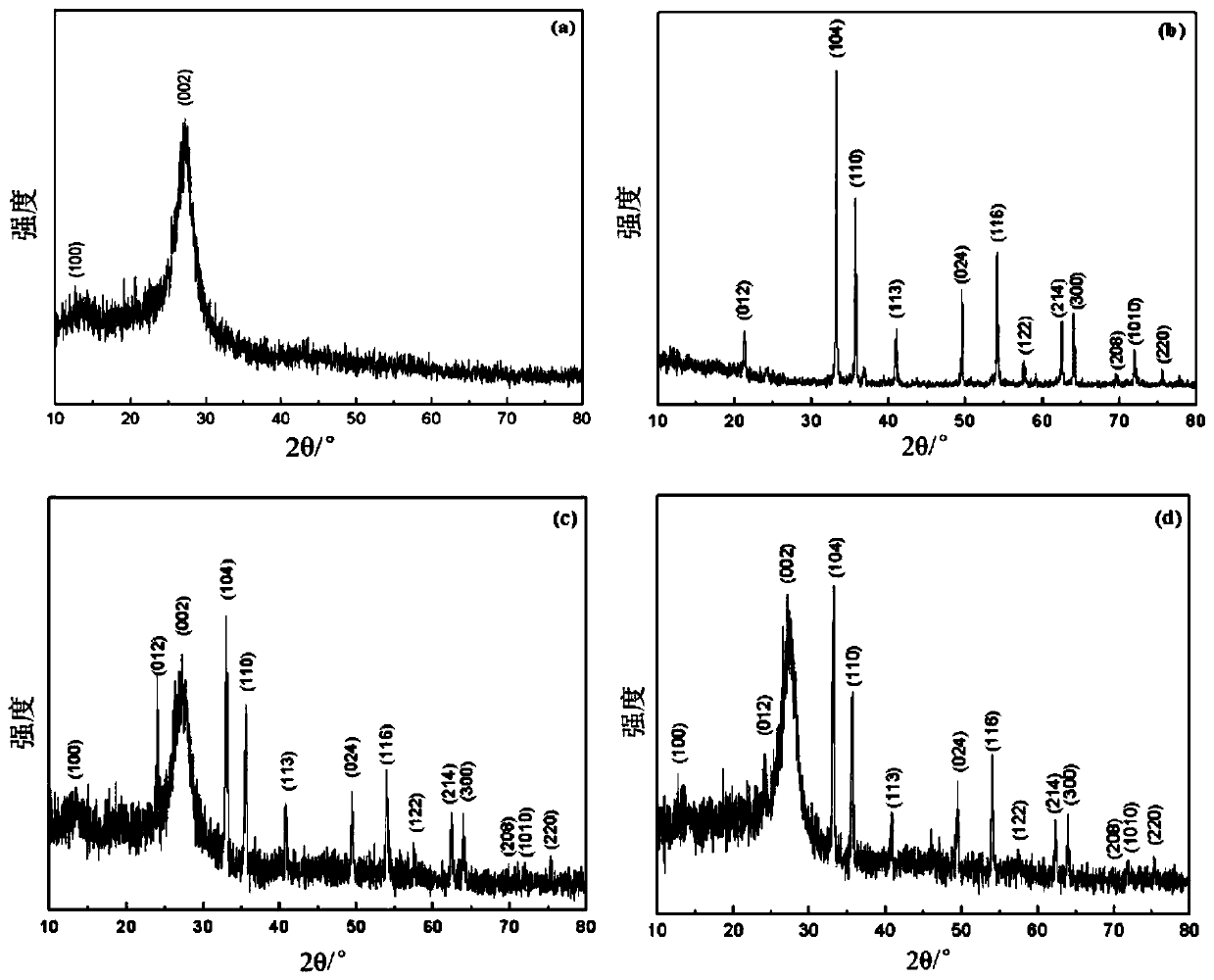

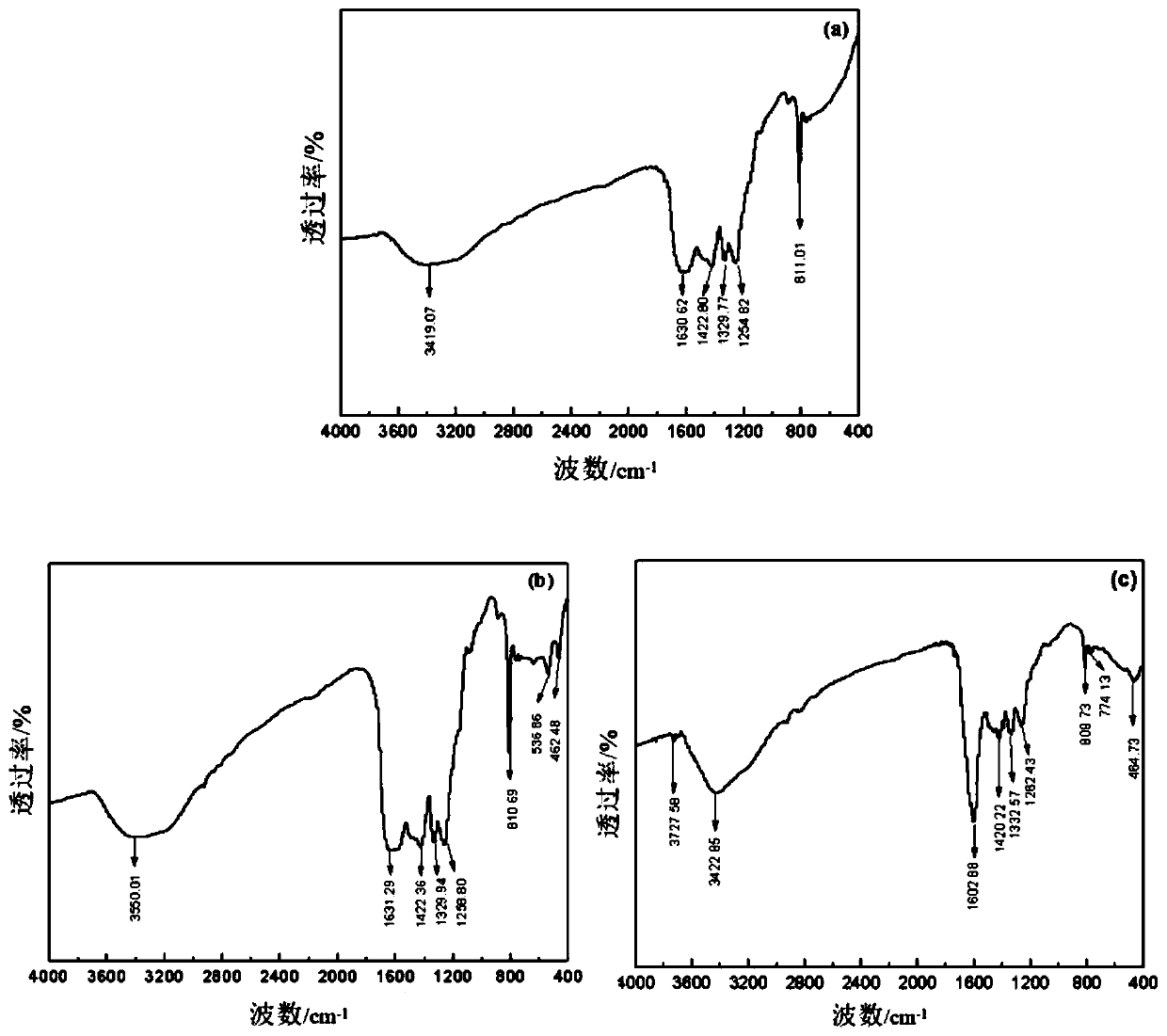

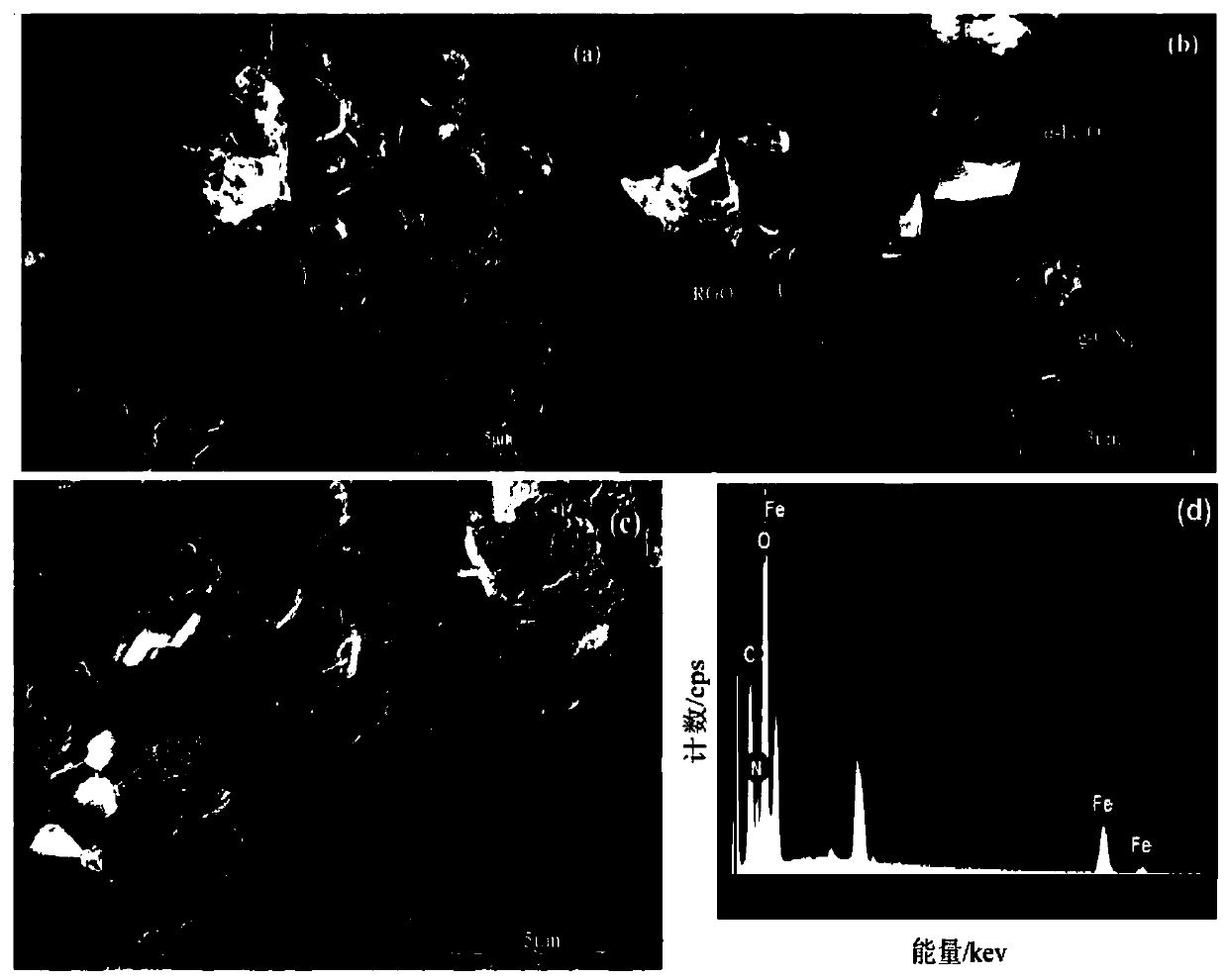

[0038] In conjunction with the following examples, for g-C 3 N 4 The preparation method of the matrix composite photocatalytic material is described in detail.

[0039] (1) g-C 3 N 4 preparation of

[0040] Weigh 12g urea and 16ml deionized water (mass ratio is 3:4), dissolve the weighed urea in deionized water, and form a homogeneous urea aqueous solution after magnetic stirring for half an hour; transfer the above urea aqueous solution to the crucible Put it into the muffle furnace, cover the crucible tightly, raise the temperature to 400°C at a heating rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com