Application of semiconductor composite material loaded with fullerene and derivative thereof in photocatalytic degradation of indoor VOCs

A technology of fullerene derivatives and composite materials, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problem of low reusability of photocatalytic materials, difficulty in dealing with VOCs pollution, and recombination rate of photogenerated carriers Advanced problems, to achieve a thorough decomposition effect, strong practicability, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

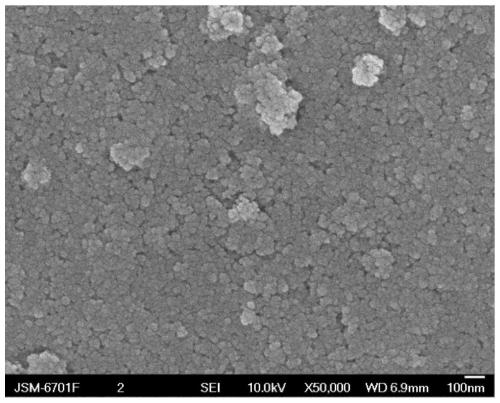

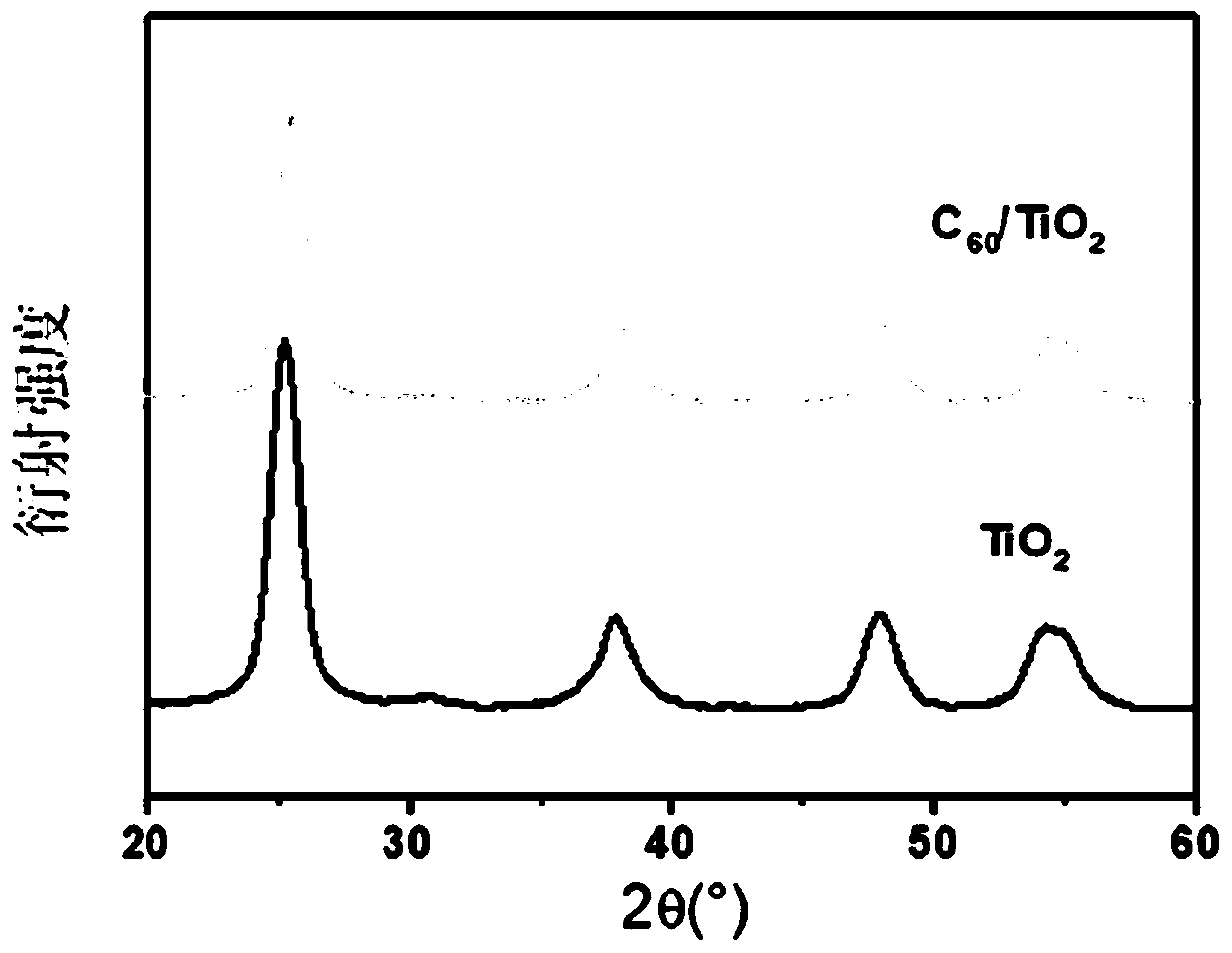

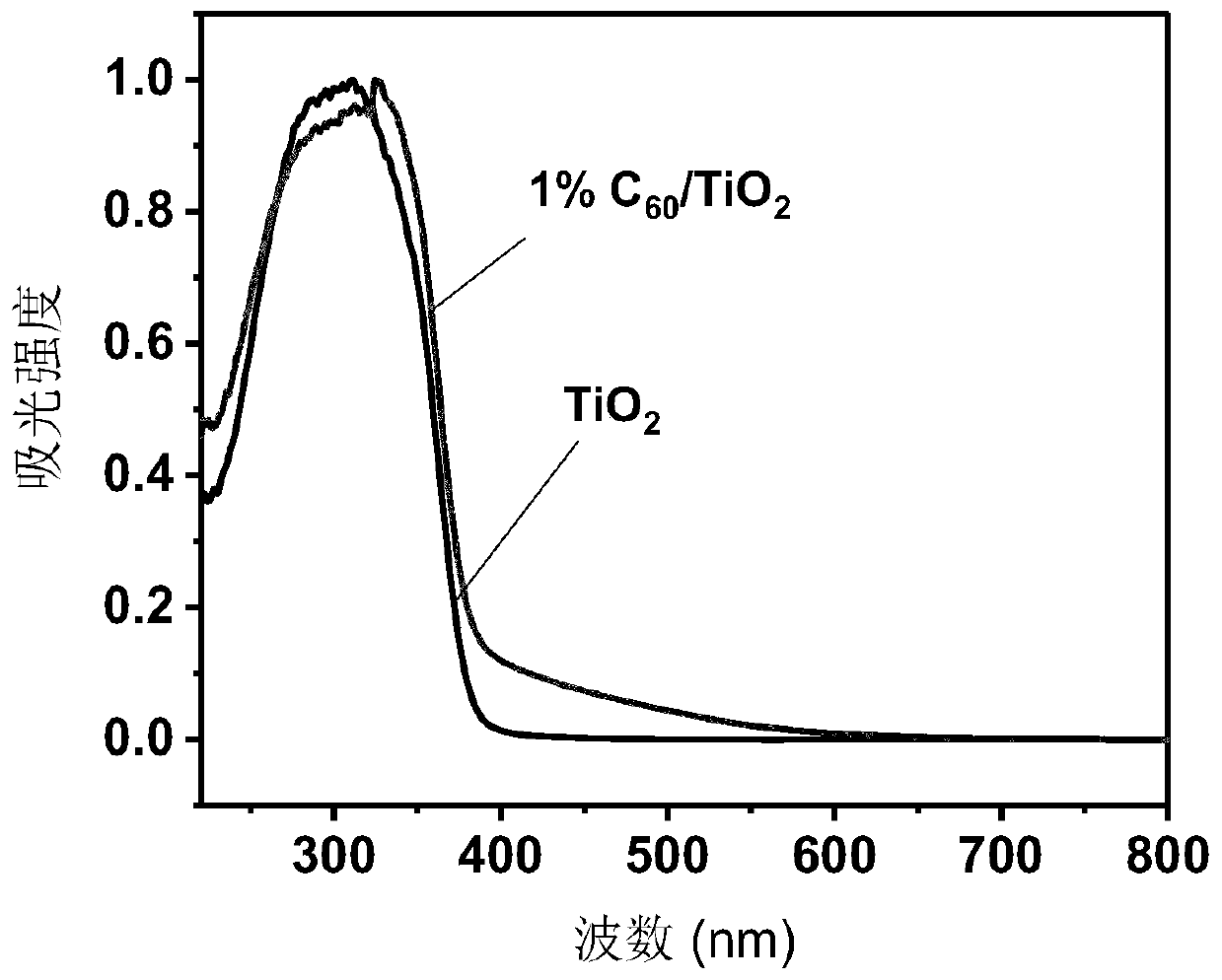

[0059] Example 1-1 Fullerene loaded TiO 2 Preparation of composite materials

[0060] TiO 2 Preparation of particles: Add 1.7ml tetrabutyl phthalate to 2ml xylene solution with stirring, then add 30ml H 2 O, continue to stir for 1h, transfer the resulting suspension to a 100ml reactor at 180°C for 10h, and cool down after the reaction to obtain a solution containing titanium dioxide nanoparticles. The solution is centrifugally filtered, washed 3 times with toluene, and then washed 3 times with absolute ethanol. times, TiO was obtained after drying overnight in a vacuum oven at 40°C 2 nanoparticles.

[0061] (1)C 60 / TiO 2 Preparation: 4mgC 60 Add 2ml of xylene to ultrasonically dissolve, then add 1.7ml of tetrabutyl phthalate to the solution containing C under stirring 60 xylene solution, followed by adding 30ml of H 2 O, continue to stir for 1h, transfer the resulting suspension to a 100ml reactor at 180°C for 10h, cool down after the reaction to obtain 60 Supported ...

Embodiment 1-2

[0067] Example 1-2 Fullerene Carboxyl Derivatives Loading TiO 2 Preparation of composite materials

[0068] Granular TiO 2 Preparation: Mix 17.5ml of ethanol and 35ml of water with ultrasound for 15min to obtain a mixed solution, then add 3.4ml of tetrabutyl phthalate to another 17.5ml of ethanol, then add tetrabutyl titanate ethanol solution dropwise under stirring into the above mixed solution, continue to stir for 2 hours, transfer the obtained suspension to a 100ml reactor at 180°C for 10 hours, cool down after the reaction to obtain a solution containing titanium dioxide particles, and centrifugally filter the solution, first wash it with deionized water for 3 times, and then use After washing with absolute ethanol for 3 times, and drying overnight in an oven at 80° C., granular titanium dioxide solid powder was obtained.

[0069] C 60 (C(COOH) 2 ) 3 Preparation: According to reference Liu Y H, Liu P X, Lu C. Tunabletribological properties in water-based lubrication ...

Embodiment 1-3

[0081] Example 1-3 Fullerene amino derivatives loaded TiO 2 Preparation of composite materials

[0082] Granular TiO 2 The preparation method is with embodiment 1-2.

[0083] C 60 Aminated derivative C 60 (EDA) n Preparation: Weigh 50 mg of solid fullerene C with an analytical balance 60 Dissolve in 25ml o-xylene solution, ultrasonically disperse for 30min, measure 50mL ethylenediamine with a measuring cylinder, add it to a 100mL conical flask with a stopper, add a magnetic stirrer, and stir for 24h with a magnetic stirrer (temperature: room temperature, speed: 1000r / min), use a solvent filter (volume: 1 L, filter membrane pore size: 200 nm) to obtain a brownish-red solution after suction filtering the reactant. The components of the solution are mainly unreacted ethylenediamine and C 60 (EDA) n and the solvent o-xylene. The obtained solution was added into a 250ml round bottom flask, and then the filtrate was completely dried by rotary evaporation using a rotary eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com