Tungsten-manganese-calcium/mesoporous tungsten trioxide composite that can be used to prepare photoanode and preparation method thereof

A tungsten trioxide, calcium oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve high photocatalytic activity and stability, wide light response range , good catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

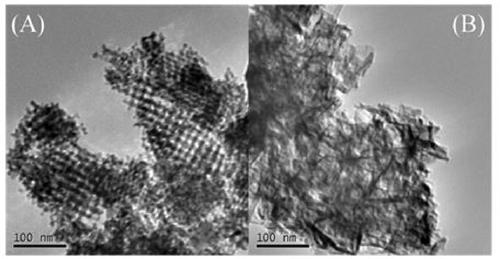

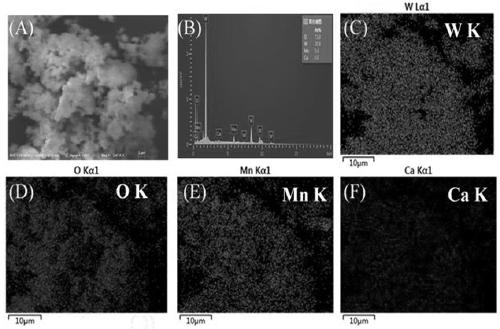

[0038] 12g of phosphotungstic acid, 8g of KIT-6 and 200 mL of absolute ethanol were mixed, stirred magnetically for 2 h, and centrifuged. The solid was washed several times with deionized water and dried at 60°C for 10 h. Calcined at 550 °C for 5 h and cooled to room temperature naturally. Disperse the obtained pale yellow solid into 200 mL hydrofluoric acid (2mol / L) and stir for 6 hours, then centrifuge. The solid was washed several times with deionized water and dried in vacuum to obtain mesoporous tungsten trioxide.

[0039] Dissolve 1.2g of calcium acetate monohydrate and 3.98g of manganese acetate tetrahydrate in 30mL of deionized water, and slowly add 30mL of KOH (8.6 mol / L) aqueous solution under magnetic stirring to obtain a brown suspension. Add 100 mL KMnO dropwise to the suspension 4 Aqueous solution (0.06 mol / L), magnetically stirred at room temperature for 8 hours, centrifuged, the solid was washed several times with deionized water, dried in vacuum, and then ca...

Embodiment 2

[0044] Add 1.9g of mesoporous tungsten trioxide and 0.10g of layered manganese-calcium oxide into a 50 mL ball mill jar, and grind on a star ball mill at 500 rpm for 4 hours, and the rest of the steps are the same as in Example 1. A porous tungsten trioxide photocatalytic material with island-like tungsten-manganese-calcium complexes on the surface was prepared, in which the mass fraction of manganese-calcium oxide was 5 wt.%. The photoanode preparation, photocatalytic reactor and photocatalytic reaction conditions are also the same as those in Example 1. After light reaction for 2 hours, when the applied voltage was 0.9V vs. RHE, the yields of hydrogen and oxygen were 1.1 and 0.4 µmol respectively; when the applied voltage was 1.0 V vs. RHE, the yields of hydrogen and oxygen were 2.0 and 0.9 µmol respectively; the applied voltage was 1.1 When V vs. RHE, the production of hydrogen and oxygen are 2.5 and 1.1 μmol, respectively; when the applied voltage is 1.2V vs. RHE, the prod...

Embodiment 3

[0046] After mixing 1.2g of phosphotungstic acid, 2.4g of KIT-6 and 30mL of absolute ethanol, stir magnetically for 2 hours, and centrifuge. The solid is washed several times with deionized water and dried at 60°C for 10 hours. Calcined at 400 °C for 5 h and cooled to room temperature naturally. The obtained pale yellow solid was dispersed into 20 mL of hydrofluoric acid (2mol / L), stirred for 6 hours, and centrifuged. The solid was washed several times with deionized water and dried in vacuum to obtain mesoporous tungsten trioxide. Add 1.86g of mesoporous tungsten trioxide obtained by this method and 0.14g of layered calcium manganese oxide prepared by the method in Example 1 into a 50 mL ball mill jar, and grind for 4 hours on a star ball mill at 500 rpm. One method is to prepare a porous tungsten trioxide photocatalytic material with island-shaped tungsten-manganese-calcium composites on the surface. The mass fraction of manganese-calcium oxide is 7 wt.%. The photoanode pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com