Smashing recycling equipment for glass waste

A technology for recycling equipment and glass waste, applied in glass recycling, recycling technology, grain processing, etc., can solve the problems of low removal efficiency of plastic rings or metal rings at the bottle mouth, dust pollution, etc., to avoid jamming, facilitate separation, The effect of avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

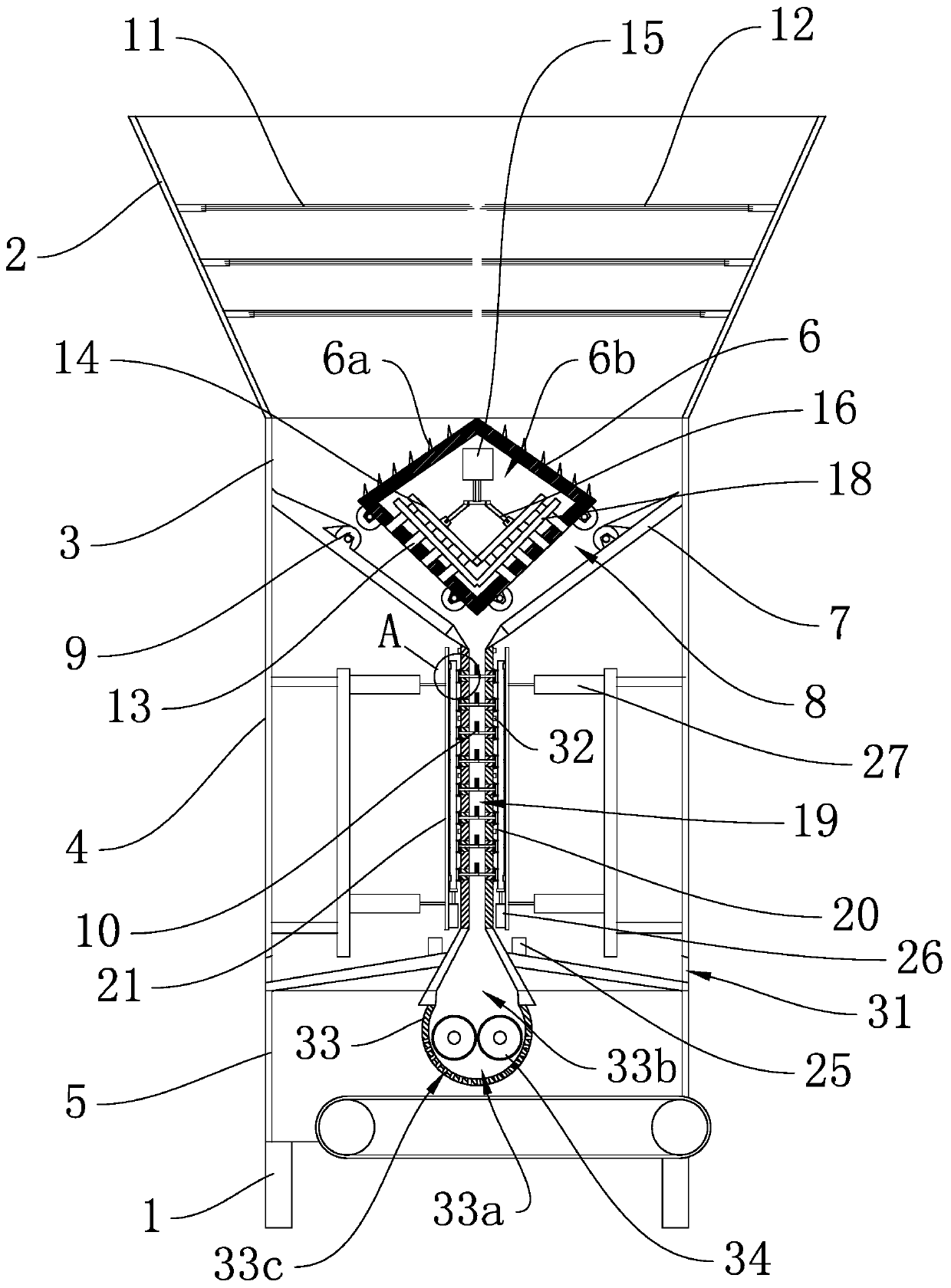

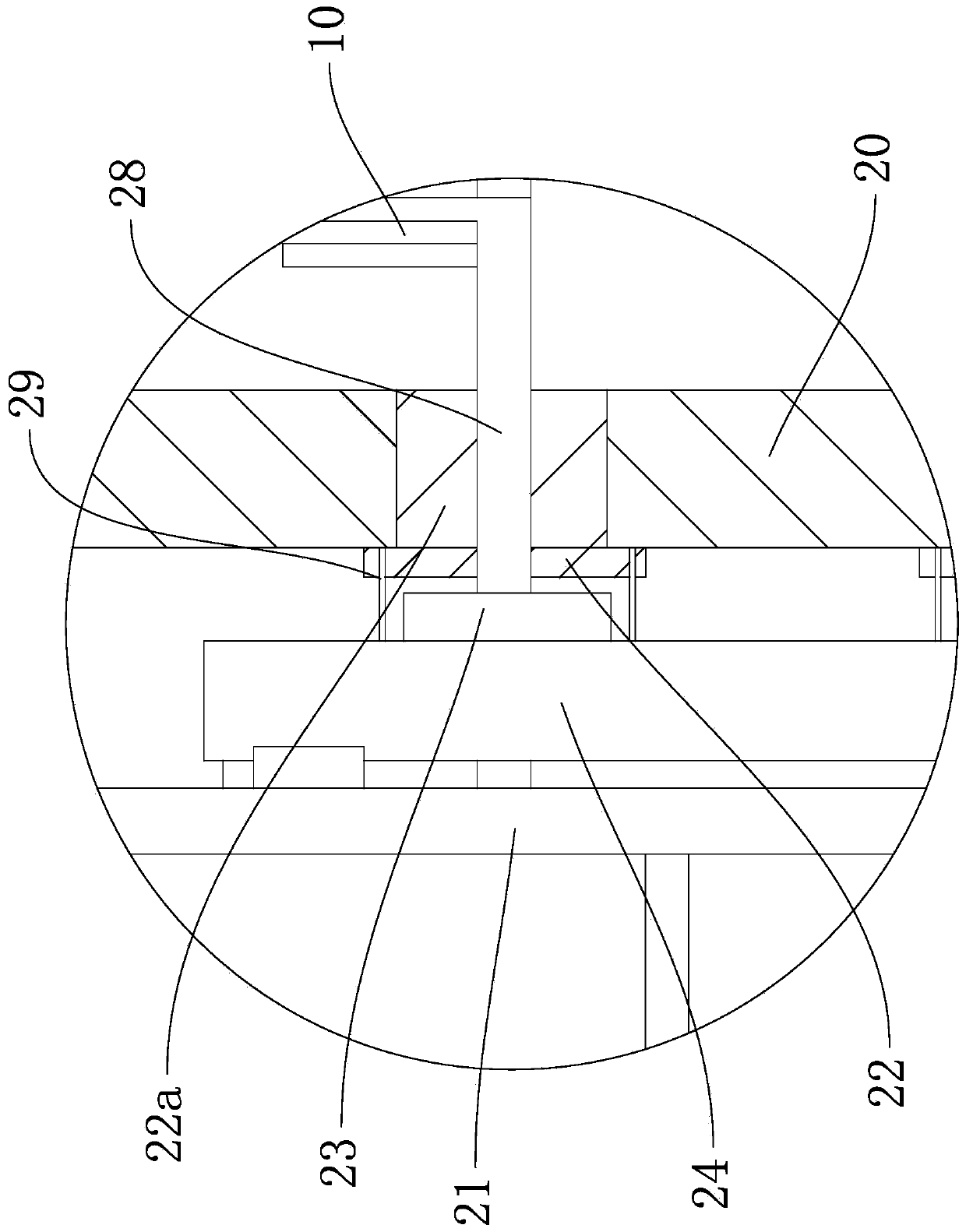

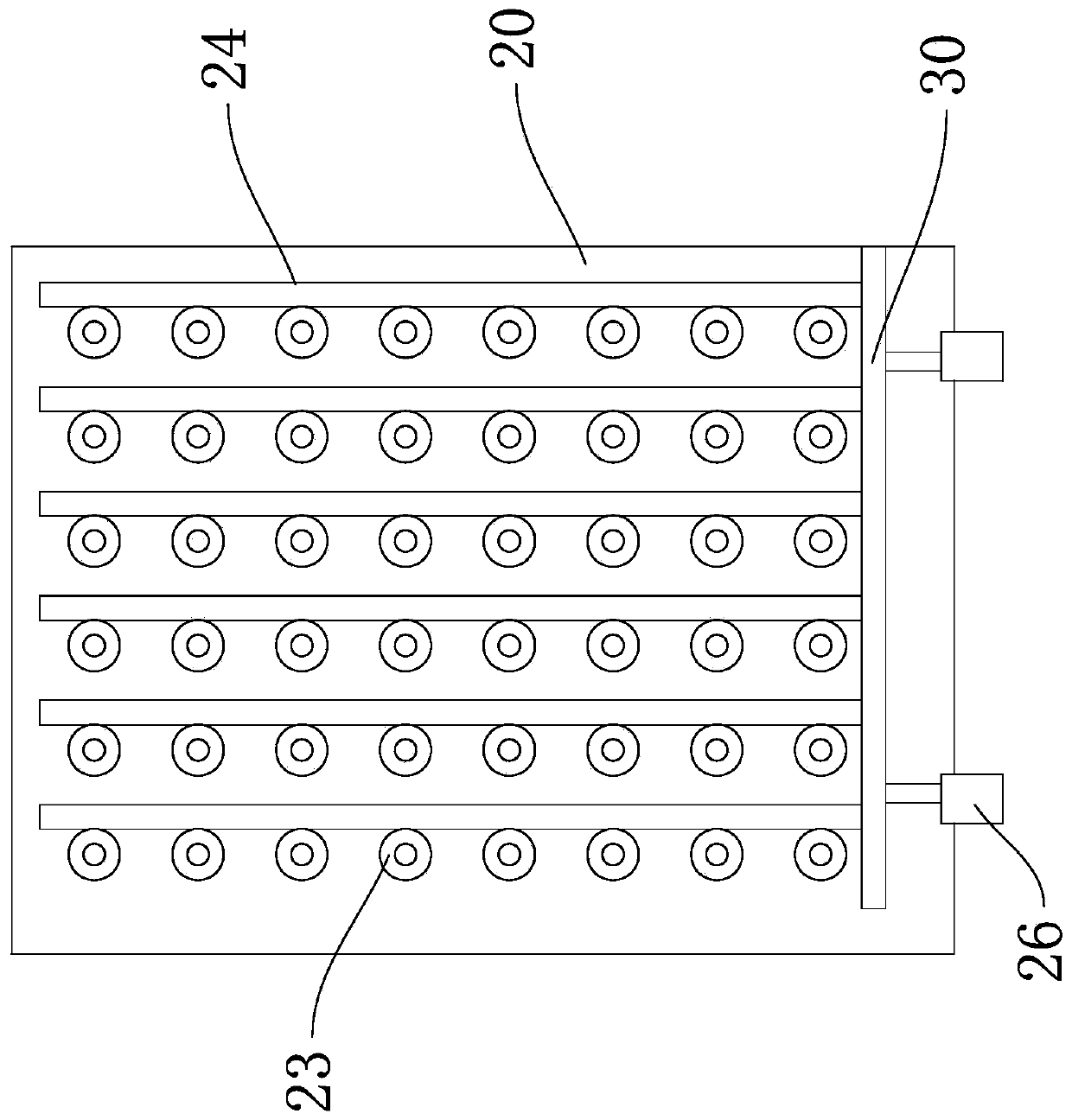

[0027] Such as Figure 1 to Figure 4 As shown, a crushing and recycling equipment for glass waste includes a frame 1, which is characterized in that a feeding funnel 2, a primary crushing box 3, a screening box 4, and a second The first-level crushing box 5 is provided with an anti-diffusion mechanism for preventing the diffusion of glass powder in the feeding funnel 2. A guide block 6 and a guide plate 7 are fixed in the first-level crushing box 3, and the guide block 6 has a number of spikes 6a. The guide surface of 6 and the guide plate 7 form a crushing channel 8 for glass bottle crushing. The size of the crushing channel 8 gradually decreases from top to bottom. A number of crushing rollers 9 are rotated in the crushing channel 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com