Manufacturing method of dislocated spliced perforated combined beam

A technology of dislocation splicing and manufacturing methods, which is applied in the manufacture of composite beams and building components, can solve the problems of increasing production costs and cycle times, and achieve the effects of convenient processing and production, guaranteed structural strength, and high pouring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Please refer to the attached figure 1 to attach Figure 5 As shown, the present invention is a method for manufacturing a composite beam with dislocation splicing openings, which includes the following steps:

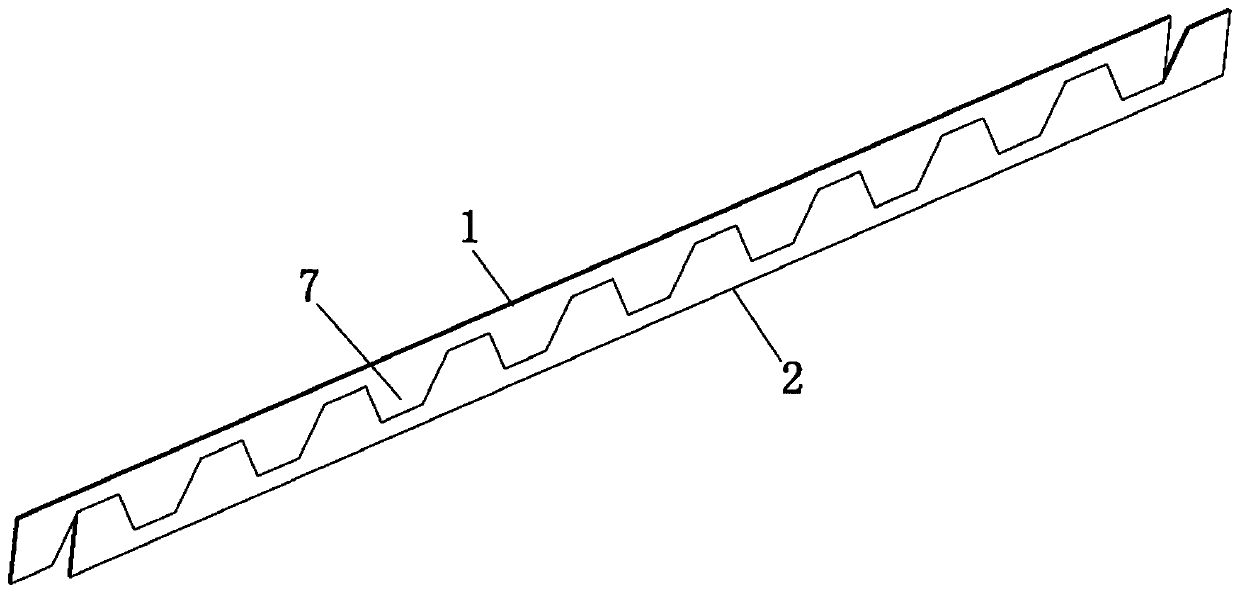

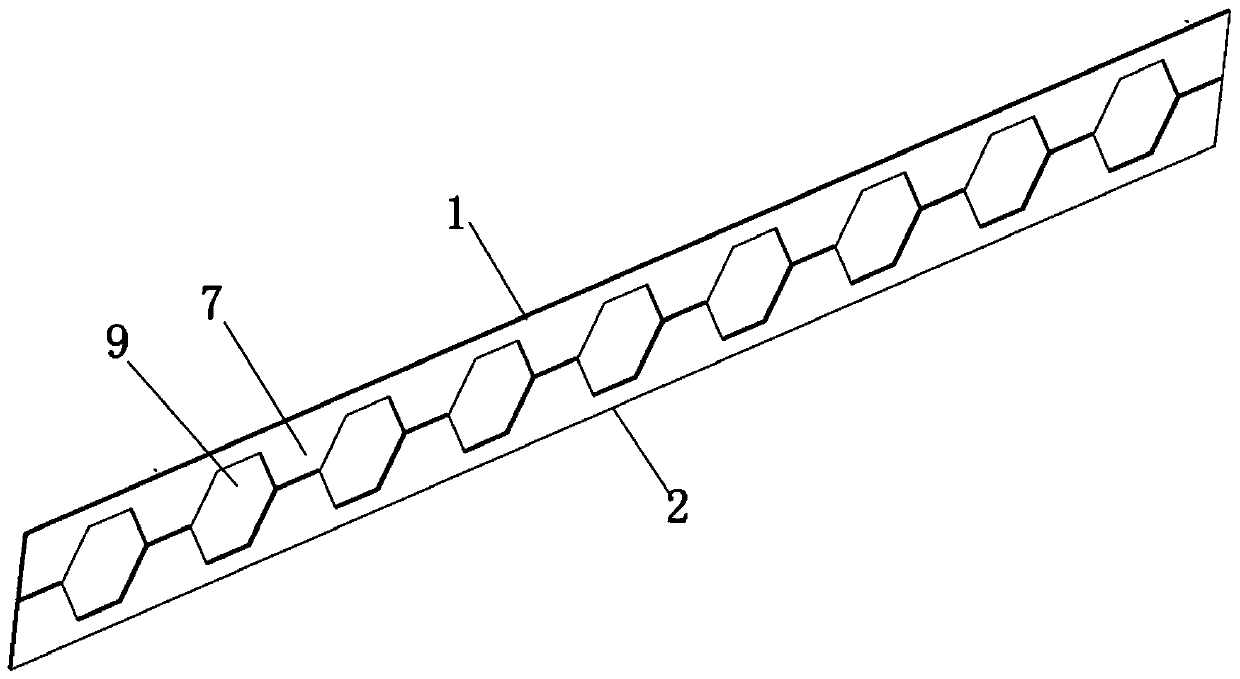

[0027] 1), according to the size of the web plate to be drilled and the size of the hexagonal hole, calculate the size of the steel plate before cutting, and blank it to form the alveolar plate I1 and the alveolar plate II2.

[0028] 2) Displace alveolar plate I1 and alveolar plate II2, align tooth crests with tooth crests for splicing, and perform full welding at each section to form a web.

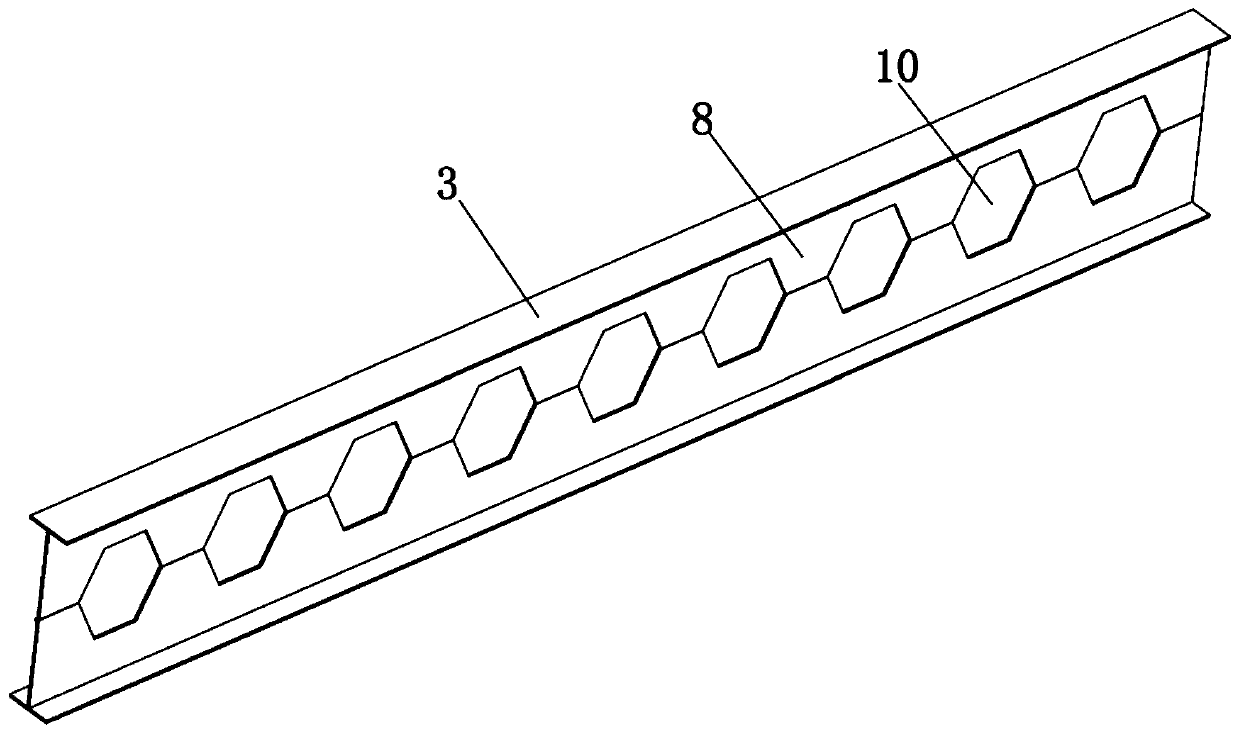

[0029] 3) The upper and lower flanges 3 are vertically welded to the outer sides of the alveolar plate I1 and the alveolar plate II2, so that the alveolar plate I1, the alveolar plate II2 and the flange 3 form H-shaped steel.

[0030] 4), weld the end plates at the ends of the alveolar plates I1 and II2, and the end plates can be used as the end plates of the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com