Integrated piezoelectric vibration resistance reducer capable of being embedded in wall face

A piezoelectric vibrator and piezoelectric vibration technology, applied in the field of piezoelectric vibration drag reduction devices and integrated piezoelectric vibration drag reducers, can solve the problems of complex structure, large space occupation, and poor versatility of drag reducers, and achieve Novel design, reduced resistance, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

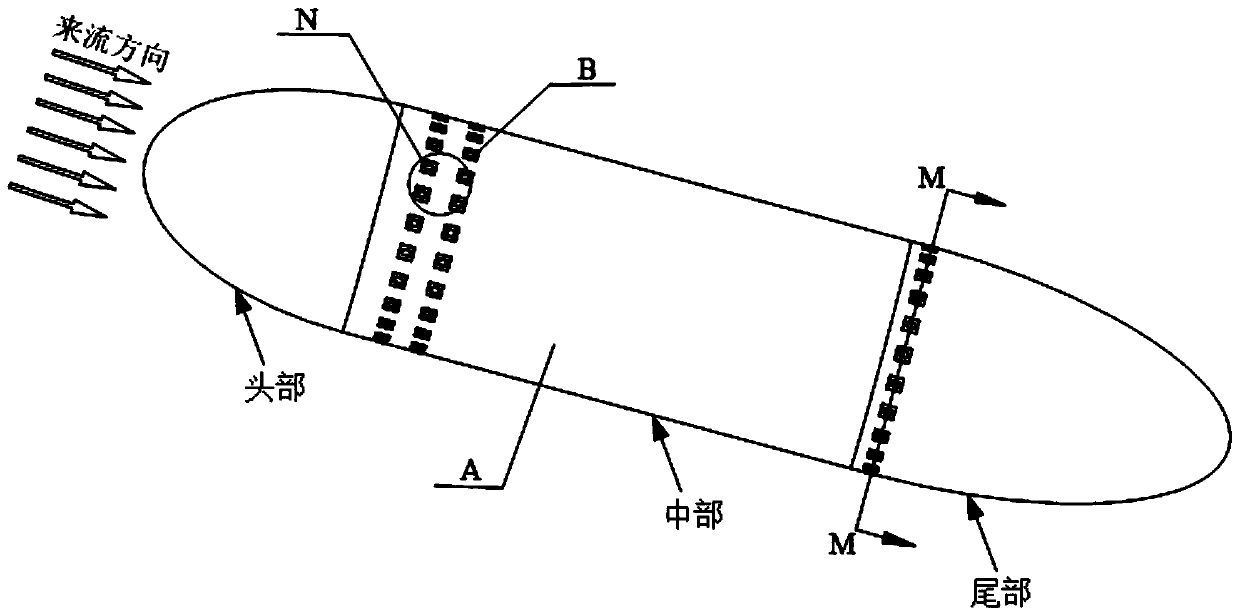

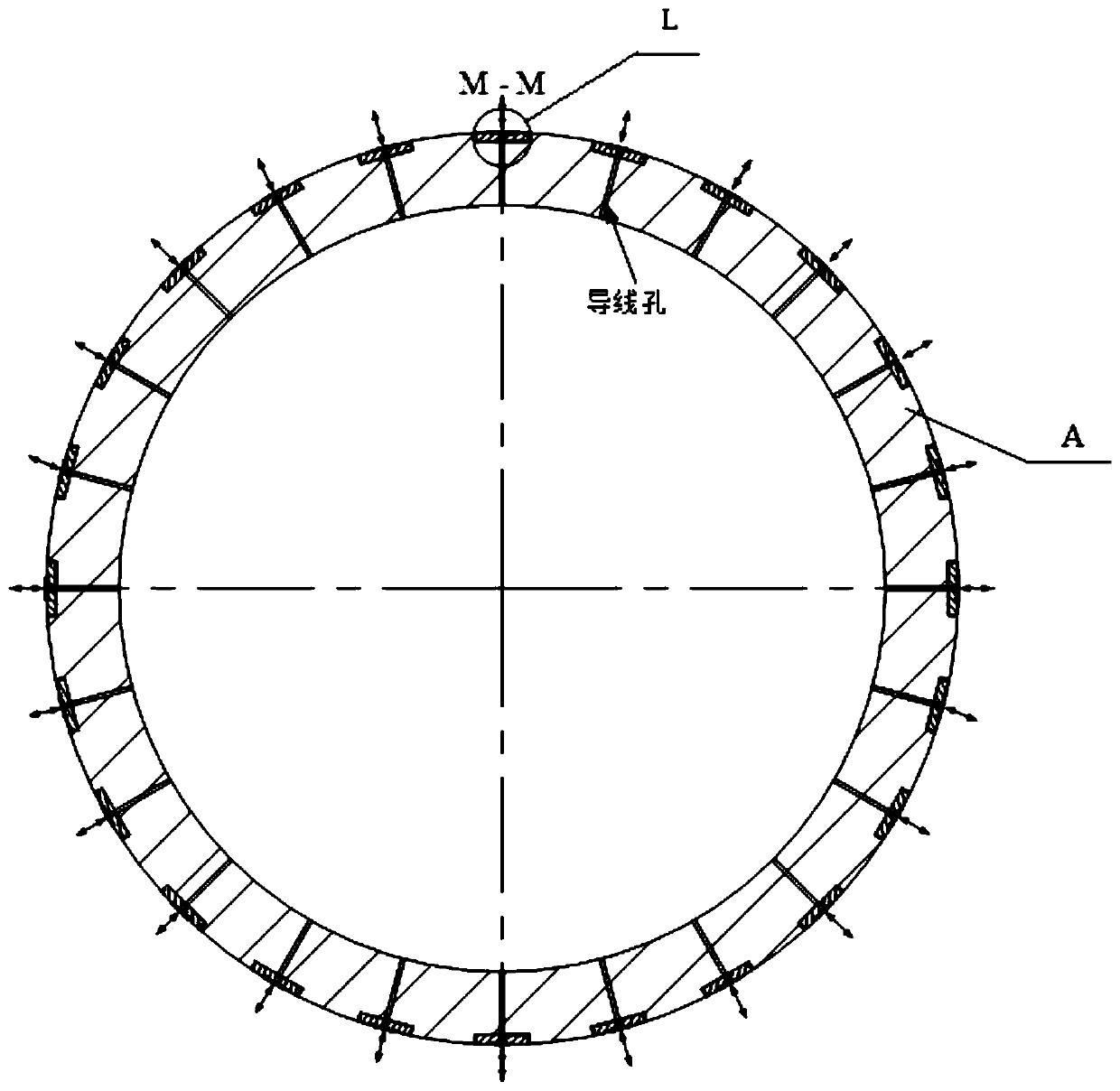

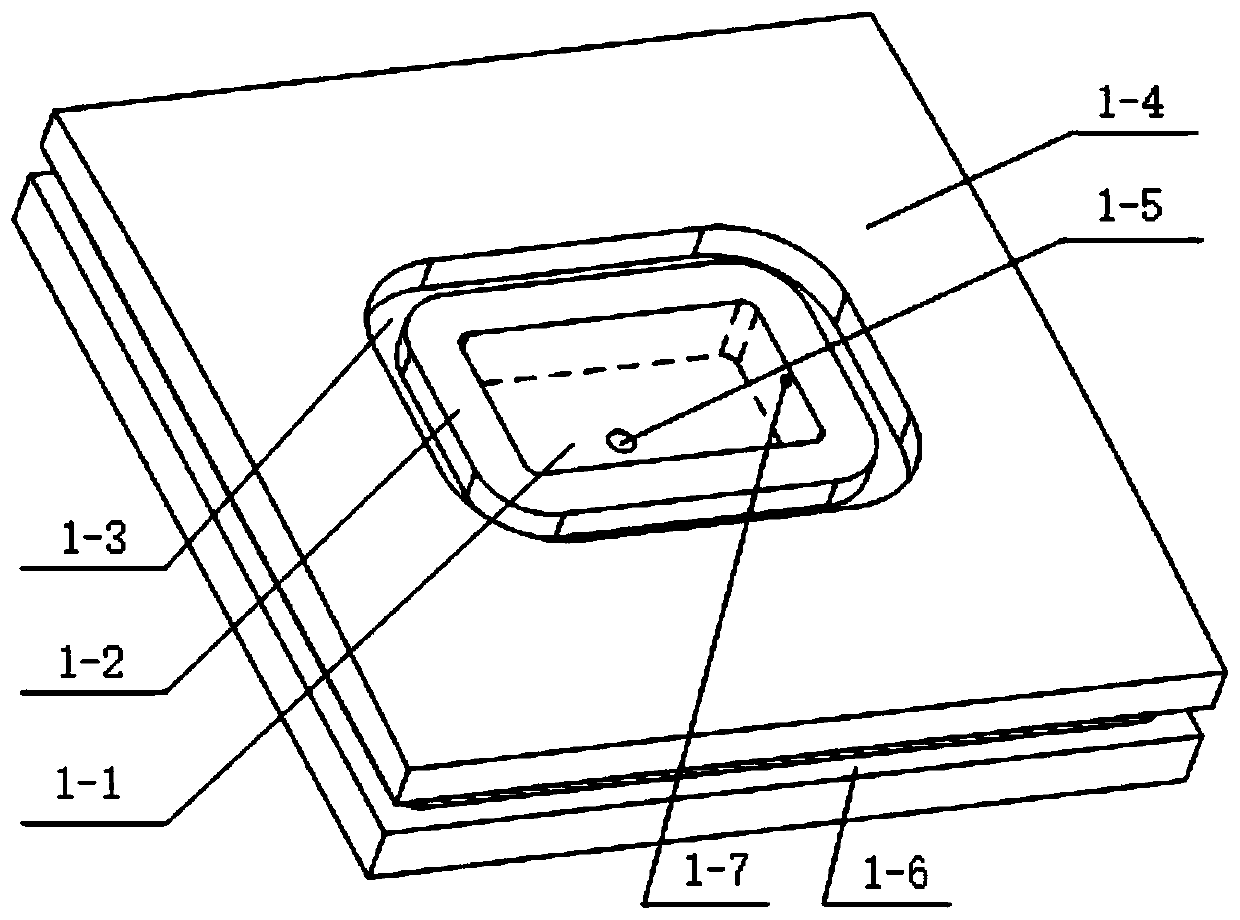

[0040] Embodiment 1: see Figure 1-4 , Figure 11-12 , an integrated piezoelectric vibration damper that can be embedded in the wall described in this embodiment includes three rows of piezoelectric vibration dampers B, and the piezoelectric vibration dampers B are embedded on the outer wall of the underwater vehicle A , the underwater vehicle A includes a head, a tail and a middle part, the head and the tail are conical, and the middle part is cylindrical, and the piezoelectric vibration damper B is specifically embedded in the middle part of the underwater vehicle A and the tail, the piezoelectric vibration damper B comprises a damper cavity 1 and a piezoelectric vibrator, and the piezoelectric vibrator comprises a copper sheet 2, a piezoelectric sheet 3, and a wire 4; the drag reducer cavity The body 1 is embedded into the outer wall of the underwater vehicle A, and the two are sealed and installed through the sealing ring II7; the copper sheet 2 is placed in the middle of...

Embodiment 2

[0043] Embodiment 2: combine below figure 1 , 2 , 5-7, and 11-12 illustrate this embodiment. The difference between this embodiment and Embodiment 1 is that the underwater vehicle A uses a cantilever type drag reducer when it works in a shallow water area with low pressure. The piezoelectric sheet 3 is pasted on the middle position of the inner surface of the copper sheet 2, the left end of the inner surface of the copper sheet 2 is glued and fixed to the reference plane 1-2, and the diaphragm 9 is pasted on the rest of the inner surface of the copper sheet 2, and the film The lower surface of the sheet 9 is glued to the horizontal plane 1-8 of the drag reducer cavity 1, and the horizontal plane 1-8 is a plane milled downward from the reference plane 1-2. The diaphragm 9 plays a role of connection and sealing. The piezoelectric strain constant matrix is d 31 When the piezoelectric sheet 3 is in the working mode, use its contraction and expansion to make the right end of th...

Embodiment 3

[0044] Embodiment 3: combine below figure 1 , 2 , 3, 8, 11-12 illustrate this embodiment, the difference between this embodiment and Embodiments 1 and 2 is that the piezoelectric sheet 3 can be replaced by a piezoelectric stack I5 in the piezoelectric vibration damper B, The piezoelectric stack I5 is located right below the copper sheet 2 . When the internal space of the underwater vehicle A is relatively large, the piezoelectric stack I5 with longitudinal vibration is adopted, and the piezoelectric stack I5 of the longitudinal vibration type adopts a piezoelectric strain constant matrix of d 33 The working mode, that is, polarization along the thickness direction, mainly produces displacement changes in the thickness direction. When the external excitation drives the piezoelectric stack 5, its vibration direction is perpendicular to the copper sheet 2, so that the copper sheet 2 can obtain a higher Large amplitude, increased drag reduction rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com