Recycled concrete

A technology of recycled concrete and recycled coarse aggregate, which is applied in the field of concrete, can solve the problems of increased water absorption rate of recycled aggregates, influence of recycled concrete compressive strength, and impact on the service life of recycled concrete, so as to achieve low water absorption, reduce Pan-alkaline phenomenon, strong rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

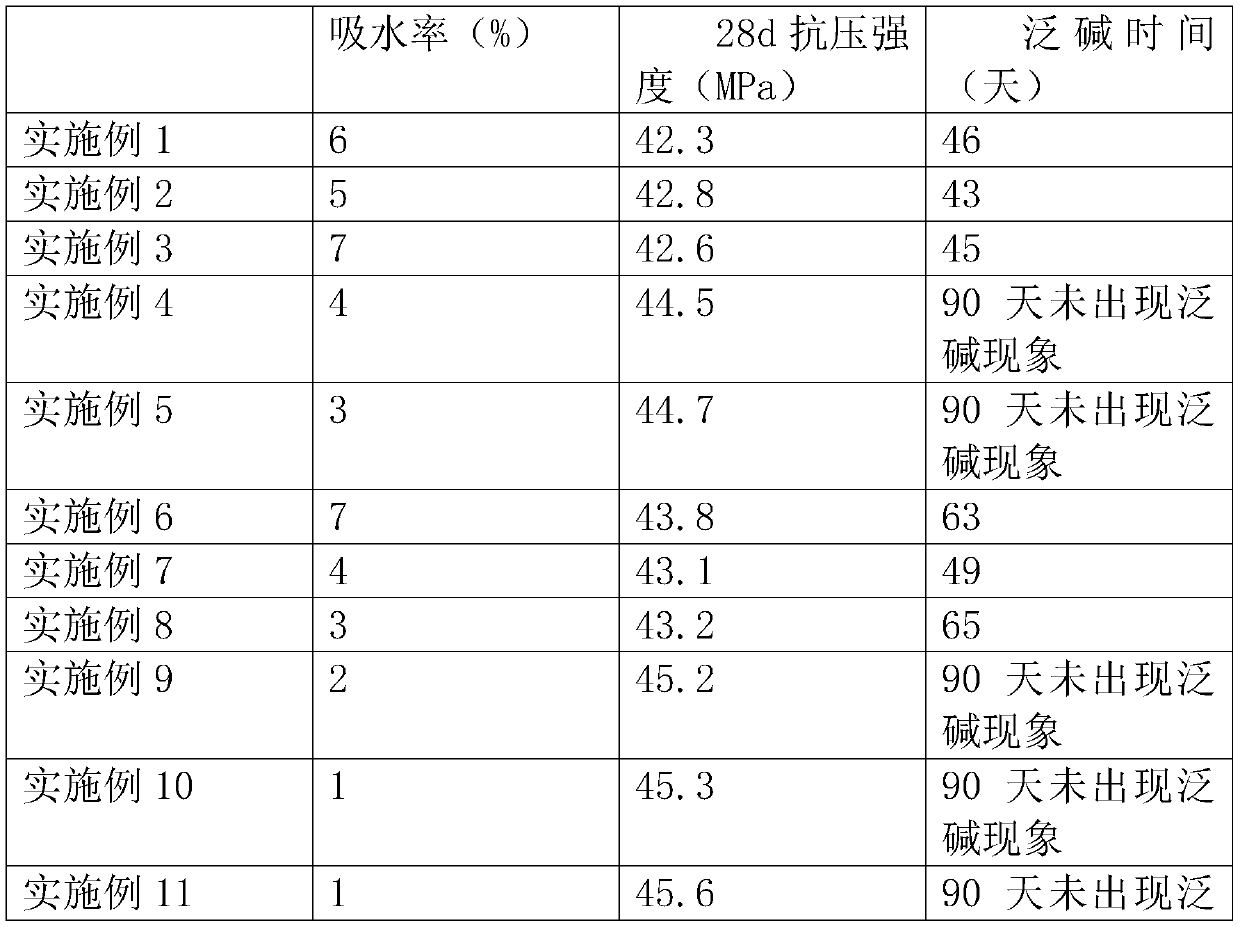

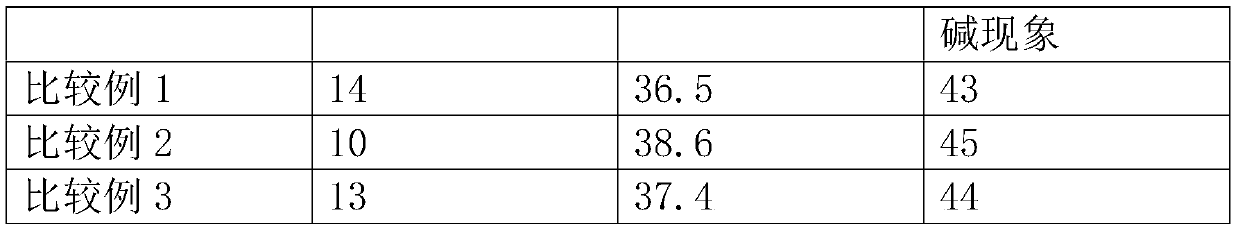

Examples

Embodiment 1

[0055] A recycled concrete comprising the following components in parts by mass:

[0056] 5kg of water; 15kg of Portland cement; 4kg of water reducing agent; 73kg of recycled coarse aggregate; 38kg of fine aggregate; 4kg of hollow glass microspheres; 5kg of acrylic acid emulsion;

[0057] In this embodiment, the particle size of the hollow glass microspheres is 30 μm.

[0058] In this embodiment, the particle size of microsilica is 1200 mesh.

[0059] The preparation method of recycled concrete is as follows:

[0060] S1. In the cement mixer, under normal temperature conditions, add 15kg of Portland cement and stir at a speed of 160r / min;

[0061] S2. Add 5kg of water and 4kg of water reducing agent while stirring, and form a premix after stirring evenly;

[0062] S3. Add 73kg of regenerated coarse aggregate, 38kg of fine aggregate, 4kg of hollow glass microspheres, and 2kg of microsilica fume to a sandstone mixer at room temperature, and stir at a speed of 120r / min. After ...

Embodiment 2

[0065] A recycled concrete comprising the following components in parts by mass:

[0066] 5.5kg of water; 13kg of Portland cement; 3kg of water reducing agent; 80kg of recycled coarse aggregate; 35kg of fine aggregate; 2kg of hollow glass microspheres; 7kg of acrylic emulsion;

[0067] In this embodiment, the particle size of the hollow glass microspheres is 33 μm.

[0068] In this embodiment, the particle size of microsilica is 1250 mesh.

[0069] The preparation method of recycled concrete is as follows:

[0070] S1. In the cement mixer, under normal temperature conditions, add 13kg of Portland cement and stir at a speed of 160r / min;

[0071] S2. Add 5.5kg of water and 3kg of water reducing agent while stirring, and form a premix after stirring evenly;

[0072] S3. Add 80kg of regenerated coarse aggregate, 35kg of fine aggregate, 2kg of hollow glass microspheres, and 1kg of microsilica fume to a sandstone mixer at room temperature, and stir at a speed of 120r / min. After s...

Embodiment 3

[0075] A recycled concrete comprising the following components in parts by mass:

[0076] 6kg of water; 14kg of Portland cement; 5kg of water reducer; 65kg of recycled coarse aggregate; 40kg of fine aggregate; 5kg of hollow glass beads; 8kg of acrylic emulsion;

[0077] In this embodiment, the particle size of the hollow glass microspheres is 35 μm.

[0078] In this embodiment, the particle size of microsilica is 1300 mesh.

[0079] The preparation method of recycled concrete is as follows:

[0080] S1. In the cement mixer, under normal temperature conditions, add 14kg of Portland cement and stir at a speed of 160r / min;

[0081] S2. Add 6kg of water and 5kg of water reducing agent while stirring, and form a premix after stirring evenly;

[0082] S3. Add 65kg of regenerated coarse aggregate, 40kg of fine aggregate, 5kg of hollow glass microspheres, and 3kg of microsilica fume to a sandstone mixer at room temperature, and stir at a speed of 120r / min. After stirring evenly, bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com