Polyarylene sulfide resin composition, molded article thereof, and surface mount electronic component

A technology of resin composition and electronic components, which is applied in the direction of electrical components, electrical solid devices, semiconductor/solid device parts, etc., can solve the problems of melting or deformation of electronic components, and achieve the effect of suppressing gas generation and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0122] Hereinafter, an Example is given and this invention is demonstrated further concretely. However, the present invention is not limited to these Examples.

[0123] 1. Evaluation method

[0124] [Bending characteristics]

[0125] ·Standard test method…ASTMD-790

[0126] ・Test piece…3.2mm (thickness)×12.7mm (width)×127mm (length)

[0127] ・Test results...the average value of the number of tests n=10

[0128] [hot water resistance]

[0129] The test piece was immersed in 95 degreeC hot water, and the change with time of the bending strength was examined.

[0130] ・Test piece…3.2mm (thickness)×12.7mm (width)×127mm (length)

[0131] ·Test method for flexural strength…ASTM D-790

[0132] ・Evaluation items... Retention of flexural strength after 1000 hours and 3000 hours with respect to initial strength

[0133] ・Test results...the average value of the number of tests n=5

[0134] [Metal adhesion strength]

[0135] Inject a polyarylene sulfide resin composition of the ...

Synthetic example 1

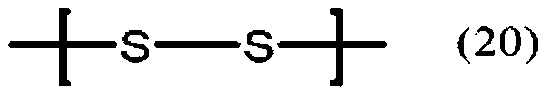

[0153] (Synthesis Example 1: Synthesis of PPS-1)

[0154] 300.0 g of p-diiodobenzene (Tokyo Chemical Co., Ltd., p-diiodobenzene purity 98.0% or more), 27.00 g of solid sulfur (manufactured by Kanto Chemical Co., Ltd., sulfur (powder)), 4,4'-dithiobisphenyl 2.0 g of formic acid (manufactured by Wako Pure Chemical Industries, Ltd., 4,4'-dithiobisbenzoic acid, Technical Grade) was heated at 180° C., and these were dissolved and mixed under nitrogen gas. Next, the temperature was raised to 220° C., and the pressure was reduced to an absolute pressure of 26.6 kPa. For the obtained molten mixture, the temperature and pressure were changed stepwise so that the absolute pressure at 320° C. became 133 Pa, and melt polymerization was performed for 8 hours. After completion of the reaction, 200 g of NMP was added, heated and stirred at 220° C., and the obtained dissolved matter was filtered. NMP320g was added to the dissolved substance after filtration, and filter cake washing and filt...

Synthetic example 2

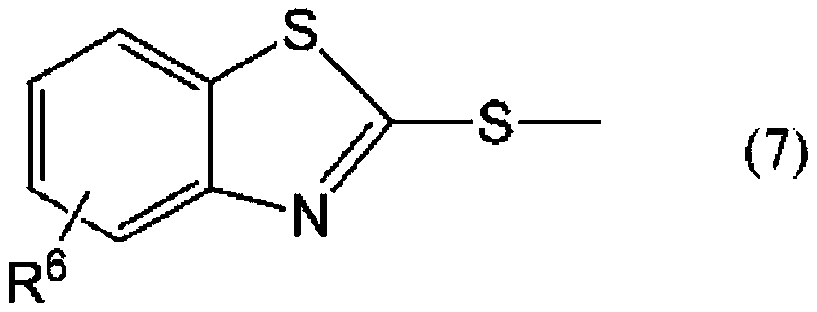

[0155] (Synthesis Example 2: Synthesis of PPS-2)

[0156] PPS resin (PPS-2) was obtained in the same manner as in Synthesis Example 1 except that "2-iodoaniline (manufactured by Tokyo Chemical Industry Co., Ltd.)" was used instead of "4,4'-dithiobisbenzoic acid". 91g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com