Strip hot-dip galvanizing and steel strip hot-dip galvanizing comprehensive continuous production line

A technology of galvanized steel strip and hot-dip galvanizing, applied in hot-dip galvanizing process, heat treatment furnace, heat treatment equipment, etc., can solve the problems of high cost, high economic pressure, reduce the capital and risks invested by entrepreneurs, and achieve line construction. The effect of cost reduction, economic pressure relief, investment capital and risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

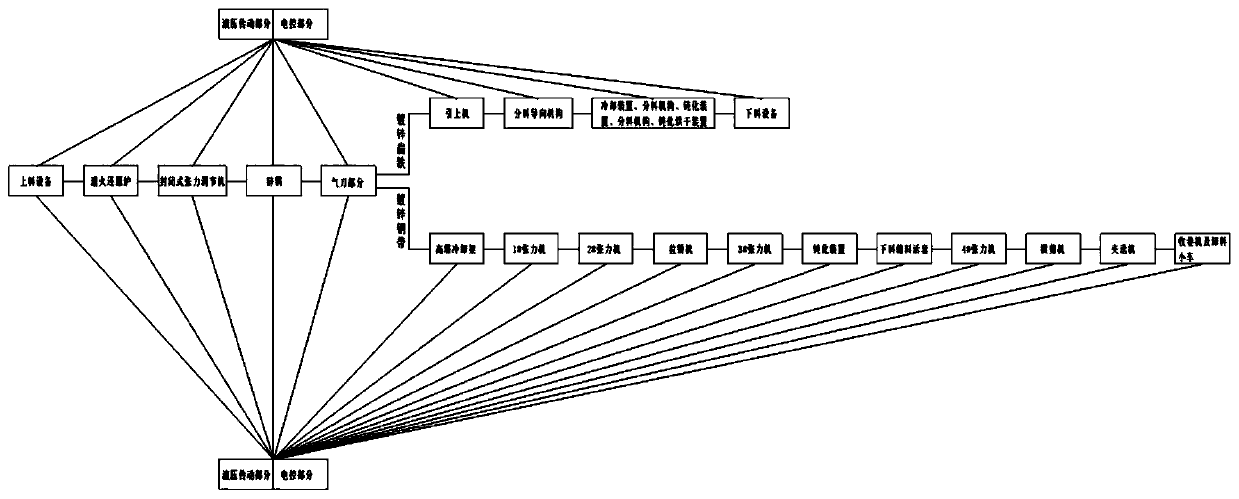

[0019] see figure 1 , an embodiment provided by the present invention: a comprehensive continuous production line for flat iron (multiple) hot-dip galvanizing and steel strip hot-dip galvanizing, including feeding equipment, annealing reduction furnace, closed tension regulator, zinc pot, lead On the machine, cooling and passivation drying device and unloading equipment, flat iron hot-dip galvanized and steel strip hot-dip galvanized is based on the pickled steel strip, in the whole production line according to the galvanized flat iron and steel strip The width specifications of the base belt are cut longitudinally into multiple flat iron and steel strips by the slitting unit in the feeding equipment, and then enter the annealing reduction furnace for annealing and reduction process. (This process is the improved Sendzimir galvanizing method. ), and then adjust the tension of the flat iron and steel strip by the closed tension regulator so that the lengths of the flat iron and...

Embodiment 2

[0029] A comprehensive continuous production line for flat iron (multiple) hot-dip galvanizing and steel strip hot-dip galvanizing:

[0030] The closed tension adjustment machine is arranged at the position before the flat iron and steel strips enter the zinc pot. The functions of the closed tension adjustment machine are: 1. Adjust the tension of the flat iron and steel strips in the furnace area to make multiple flat irons and steel strips 2. Carry out "reshaping" treatment on the deformation of the flat iron and steel belt in the furnace area due to heat radiation, so that the length of the flat iron and steel belt when entering the zinc pot is consistent.

[0031] According to different specifications of flat iron and steel strips, control the temperature of the furnace zone in each section of the annealing reduction furnace, such as the open flame section, the radiation reduction section, the slow cooling section, and the fast cooling section, so that after the completion ...

Embodiment 3

[0033] A comprehensive continuous production line for flat iron (multiple) hot-dip galvanizing and steel strip hot-dip galvanizing:

[0034] When tracking the transverse shear to complete the transverse shearing process, the tracking transverse shear needs to track the process speed of the flat iron and steel strip first, and the transverse shearing process will not start until the tracking speed of the tracking transverse shear is consistent with the process speed of the flat iron and steel strip. A problem has just arisen like this, the flat iron of different thickness specifications and steel strip process speed are not the same. The thinner the flat iron and steel strip, the faster the process speed, and the thicker the flat iron and steel strip, the slower the process speed. That is to say, the process speed of flat iron and steel strip with different thickness is different in the production process, so the tracking time and tracking distance of tracking cross shear are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com