A method for preparing ultra-high water filling materials by using iron-aluminum series high-activity materials in conjunction with industrial solid waste

A filling material and ultra-high water technology, which is applied to filling materials, mining equipment, earth square drilling and mining, etc., can solve the problems of excessive consumption of high water filling materials, unadjustable initial and final setting times, waste of clay and other resources, and achieve Alleviate the problem of land occupation by solid waste, considerable economic and social benefits, and the effect of alleviating economic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

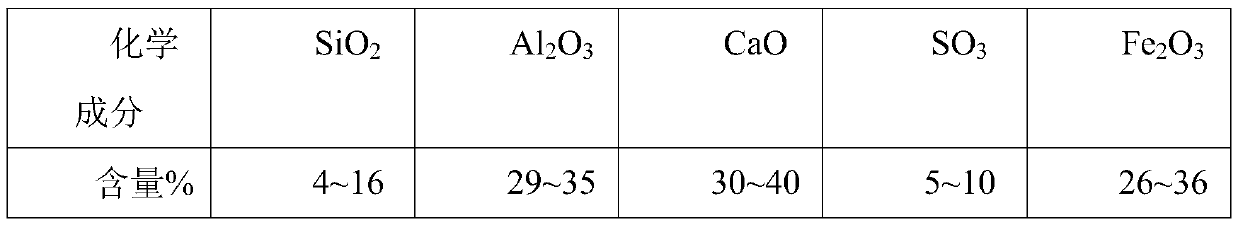

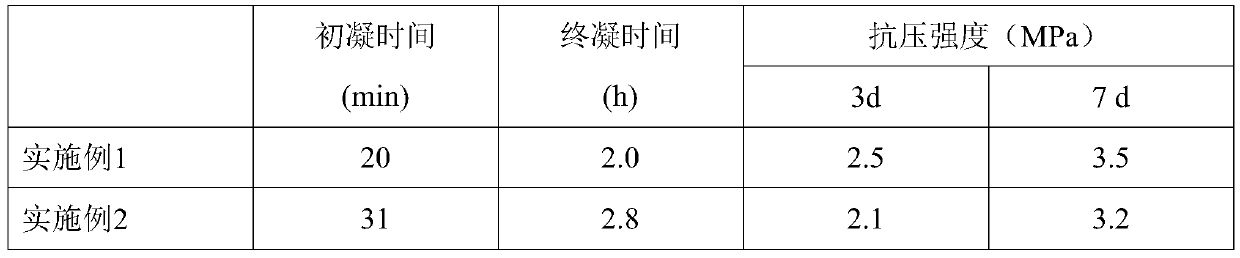

[0052] Dry solid waste-based highly active materials, coal gangue, iron tailings, slag and desulfurized gypsum until the moisture content is not greater than 5%. The solid waste-based highly active material, coal gangue, iron tailings and slag are crushed, and mixed with desulfurized gypsum. In terms of solid matter, the solid waste-based high-active material is 17 parts by weight, the coal gangue is 15 parts by weight, and the iron tail 30 parts by weight of ore, 27 parts by weight of slag and 5 parts by weight of desulfurized gypsum, and the prepared matrix material should meet the standard of less than 10% of sieve over 0.10mm. Get above-mentioned base material, add the quick-setting agent (H-508 concrete quick-setting agent) of base material quality 1%, the expansion agent (JQ-QF type high-performance fiber expansion agent) of 1.2%, the dispersant (stearic acid ), take another 92 parts of water, the quality of every 2 parts of water is the same as the quality of the above-...

Embodiment 2

[0054] Dry solid waste-based highly active materials, coal gangue, iron tailings, slag and desulfurized gypsum until the moisture content is not greater than 5%. The solid waste-based highly active material, coal gangue, iron tailings and slag are crushed, and mixed with desulfurized gypsum. In terms of solid matter, the solid waste-based high-active material is 20 parts by weight, the coal gangue is 16 parts by weight, and the iron tailing 28 parts by weight of ore, 24 parts by weight of slag and 8 parts by weight of desulfurized gypsum, and the prepared matrix material should meet the standard of less than 10% of the sieve over 0.10mm. Get above-mentioned base material, add the quick-setting agent (H-508 concrete quick-setting agent) of base material quality 0.7%, the expansion agent of 1% (JQ-QF type high-performance fiber expansion agent), the dispersant of 0.8 (stearic acid ), take another 92 parts of water, the quality of every 2 parts of water is the same as the quality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com