Ferro-aluminate phase marine gel material and preparation method thereof

A ferroaluminate and gel material technology, which is applied in cement production, etc., can solve the problems of impermeability, poor erosion resistance, and unsatisfactory performance, etc., and achieve the effects of anti-seawater erosion, low price, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The iron-aluminum series highly active materials, iron tailings, slag and desulfurized gypsum are dried until the moisture content is not greater than 5%. Crush the iron-aluminum-based high-active material, iron tailings and slag, and mix them with desulfurized gypsum. In terms of solid mass, the iron-aluminum-based high-active material is 45g, iron tailings is 25g, slag is 25g and desulfurization gypsum is 5g , the formulated matrix material should meet the standard of less than 10% of the sieve residue of 0.10mm, and the chemical composition percentage of the iron-aluminum series high-activity material is SiO 2 5%, Al 2 o 3 30%, CaO 30%, SO 3 5%, Fe 2 o 3 30%. Take the above matrix material, add 1g of A880 quick-setting agent, 0.5g of TWPZ-1 expansion agent, and 0.5g of NNO dispersant in the mass of the matrix material, and mix thoroughly to prepare the ferroaluminate phase marine cementitious material.

Embodiment 2

[0041] The iron-aluminum series highly active materials, iron tailings, slag and desulfurized gypsum are dried until the moisture content is not greater than 5%. The iron-aluminum-based high-active material, iron tailings and slag are crushed, and mixed with desulfurized gypsum. In terms of material mass, the iron-aluminum-based high-active material is 50g, and its chemical composition percentage is SiO 2 4%, Al 2 o 3 29%, CaO 31%, SO 3 5%, Fe 2 o 3 31%, 20g of iron tailings, 20g of slag and 10g of desulfurized gypsum, and the prepared matrix material should meet the standard of less than 10% of sieve over 0.10mm. Take the above matrix material, add 0.7g of A880 quick-setting agent, 0.1g of TWPZ-1 expansion agent, and 0.8 of NNO dispersant, and mix thoroughly to prepare the ferrite-aluminate phase marine cementitious material.

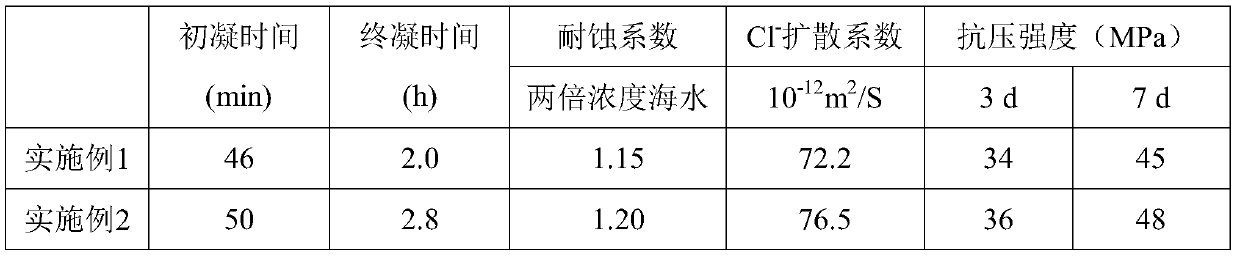

[0042] The properties of the ferro-aluminate phase marine cementitious material prepared in Example 1-2 are shown in Table 1:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com