Inner pull anchor cable structure of long-span cutting top roadway-forming roof

A large-span, anchor cable technology, used in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of uneven settlement of the roof, avoid tearing, not easy to fall off, and improve the reinforcement strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

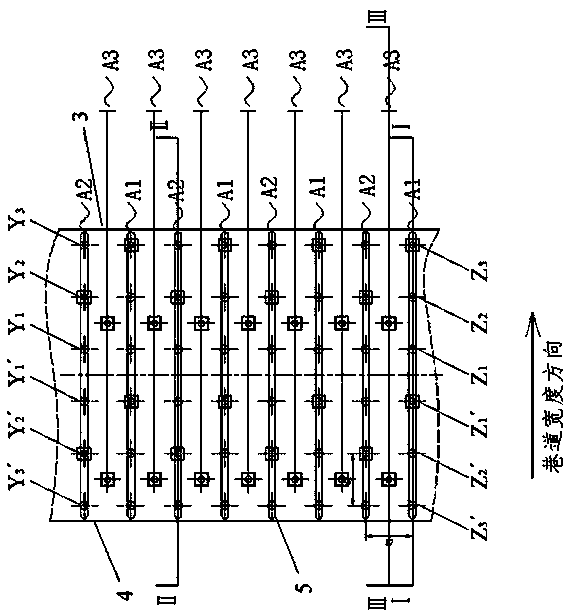

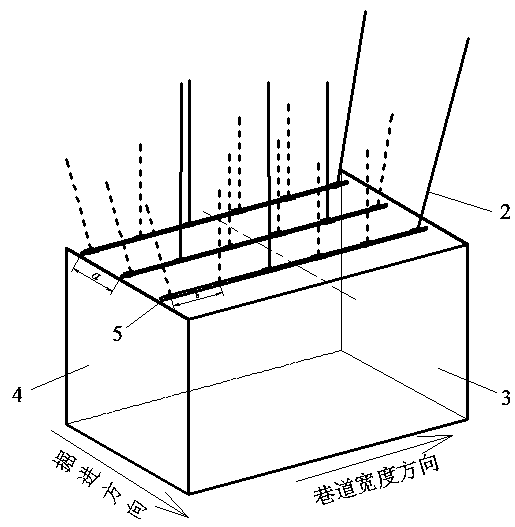

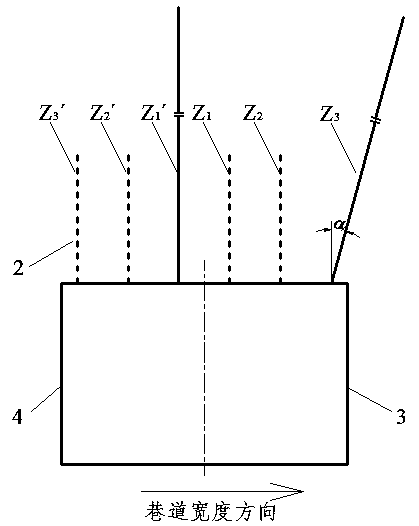

[0029] like figure 1 As shown, during the excavation, the roadway 1 supports the roof 2 while excavating: when the roadway 1 reaches the first distance along the excavation direction, the roof 2 is supported by the first anchor cable system A1; when the roadway 1 continues to excavate to the first distance Two distances, the roof 2 is supported by the second anchor cable system A2; along the roadway excavation direction, the first anchor cable system A1 and the second anchor cable system A1 are arranged alternately, and the distance between them is 600mm≤a ≤1200mm. Step 1: If figure 1 , 2 As shown in and 3, the support of the first anchor cable system A1 includes the following steps: along the roadway width direction, on the roadway roof 2 from the roadway center line, to the solid coal side 3 anchor cables are named Z in turn 1 ,Z 2 ,Z 3 ;To the gob side 4, the bolt cables are named Z in sequence 1 ',Z 2 ',Z 3 ’; anchor cable spacing 600mm≤b≤1200mm; anchor cable Z is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Preload | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com