Drying device used in tobacco industry

A drying device and industry technology, applied in the direction of tobacco drying, drying, drying machine, etc., can solve the problems of energy waste, unfavorable environmental protection, increase energy consumption, etc., achieve uniform heating, reduce waste, and benefit the environment the protective effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

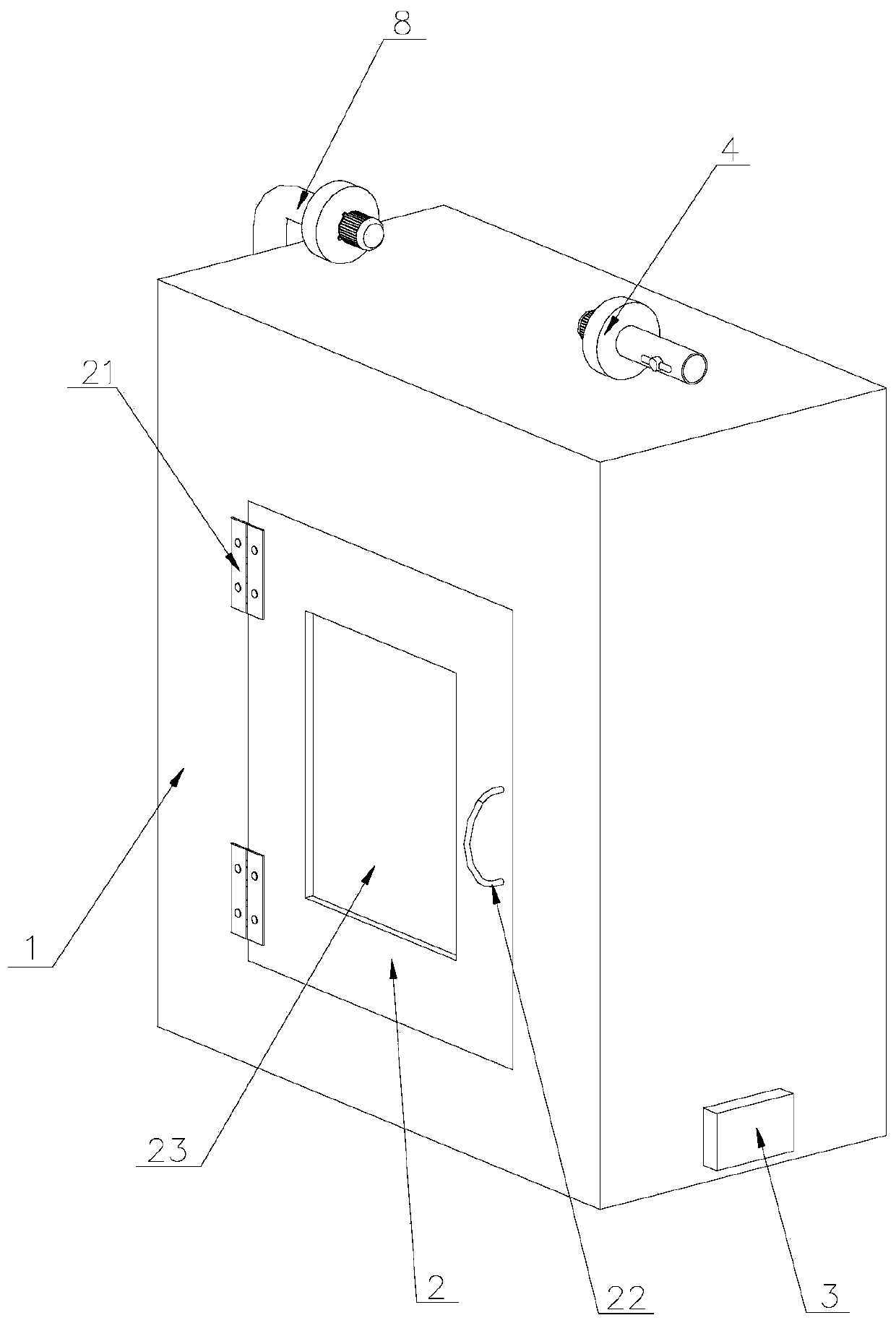

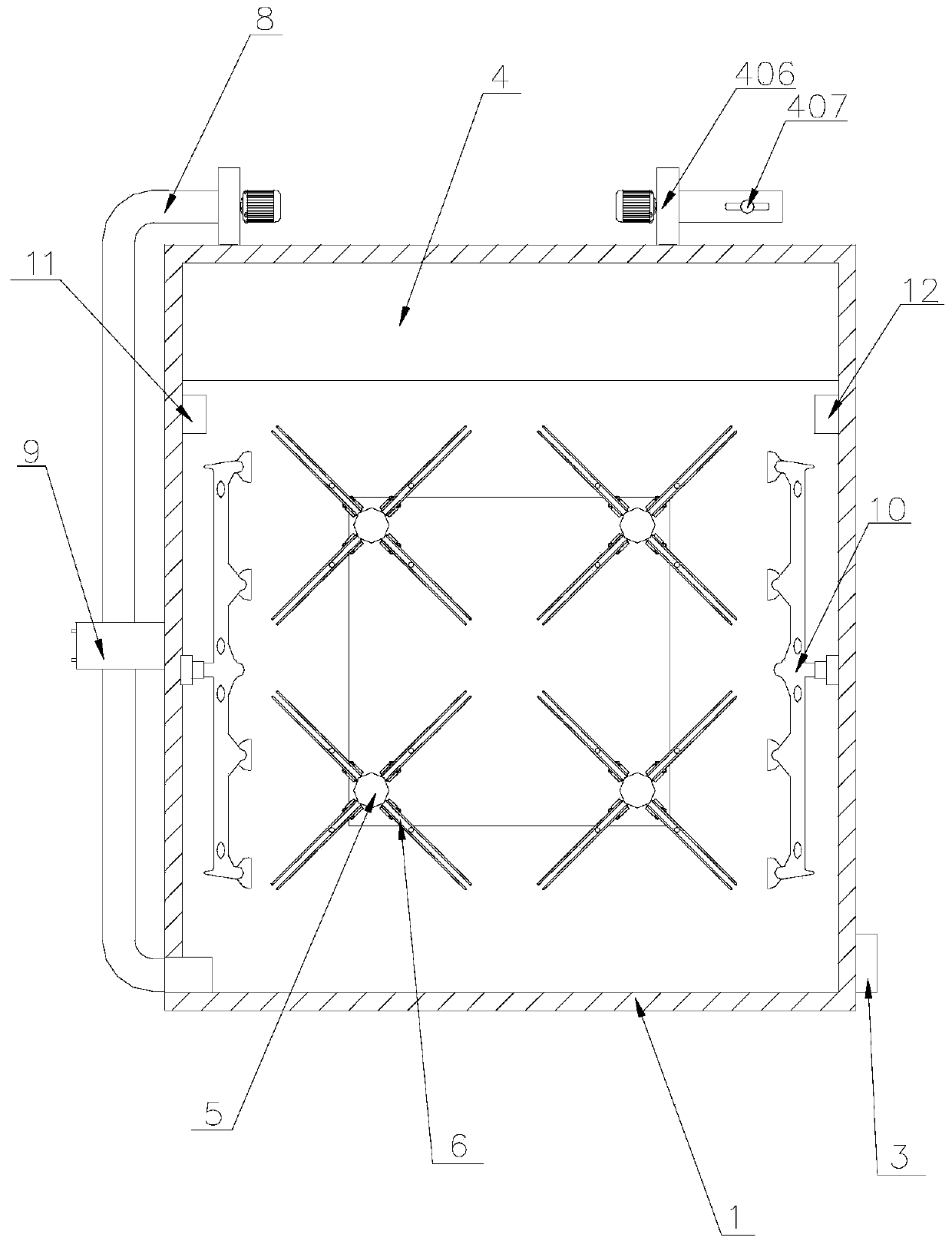

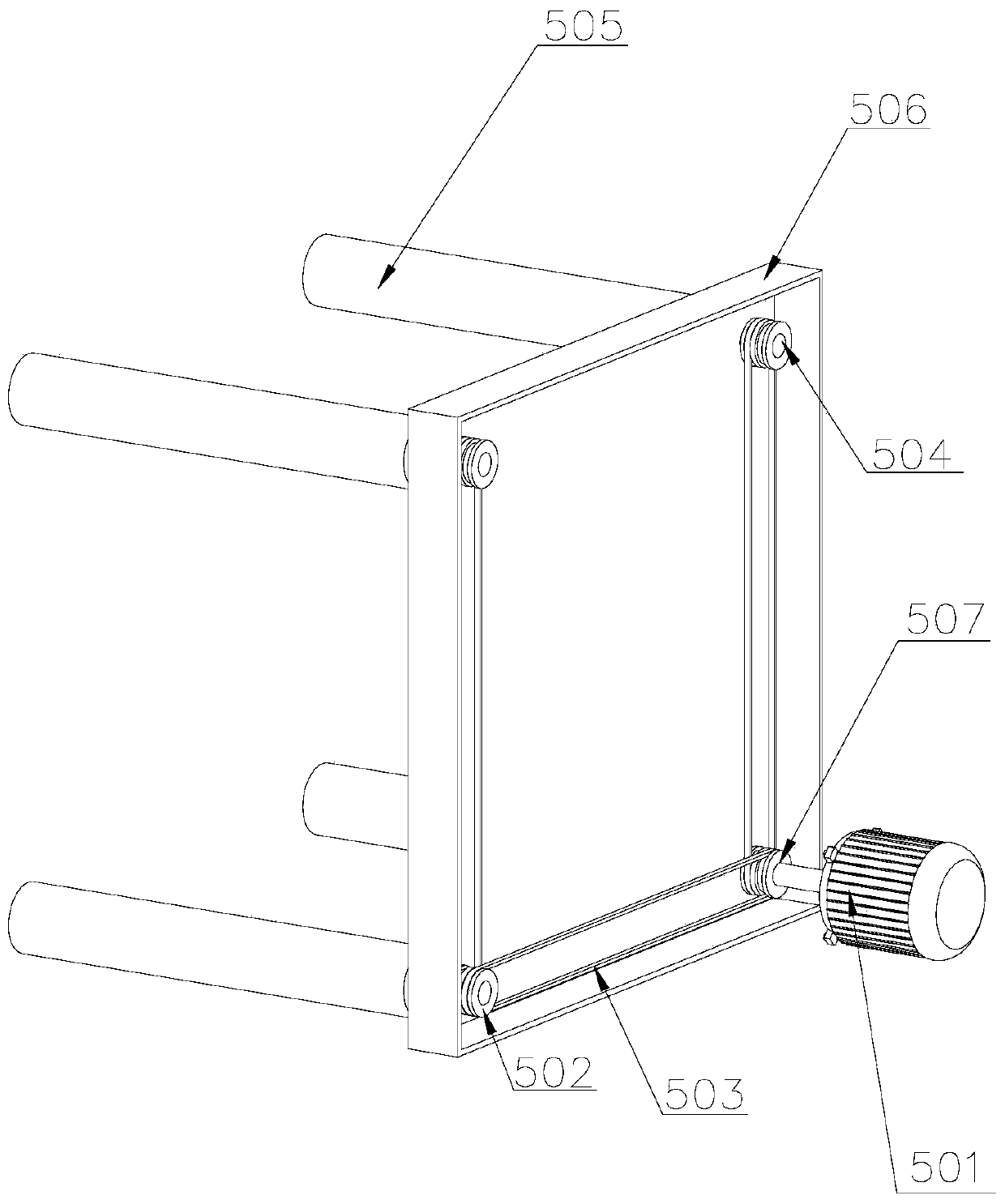

[0048] Such as Figure 1-9 As shown, a drying device for the tobacco industry includes a working box 1, a movable door 2, a heating device 4, a power unit 5, a drying rack 6, a fixing device 7, and a gas circulation device 8. The working box 1 There is a dodge door 2 on the top, and a handle 22 is provided on the dodge door 2. The dodge door 2 and the working box body 1 are hinged through a hinge 21 to facilitate the opening and closing of the dodge door 2. Put the tobacco to be dried into the To the inside of the working box 1 for drying, the top of the working box 1 is provided with a heating device 4, and the inner wall of one side of the working box 1 is provided with a temperature sensor 11, and the temperature sensor 11 adopts a commercially available mature product For example, the model 00PT100 platinum resistance temperature sensor produced by Shanghai Nijing Electronic Technology Co., Ltd. senses the temperature inside the working box 1 through the temperature sensor...

Embodiment 2

[0060] Such as Figure 10-11 As shown, the difference from Embodiment 1 is that the fixing device 7 includes a vertical plate 706, a first screw 707, a movable block 709, a second screw 710, a first round block 711, a second round block 714, and a sleeve 715 , fixed legs 716, the vertical plate 706 is arranged on both sides of the end of the placement frame 602, between the two placement frames 602, the middle part of the vertical plate 706 is provided with a through hole 708, so that the gas passes through the vertical plate 706 and the placement frame 602 Tobacco contact, the upper and lower sides of the vertical plate 706 are symmetrically provided with a number of first screw rods 707, the vertical plate 706 is provided with threaded holes that cooperate with the first screw rods 707, and the end of the first screw rod 707 is provided with a first round Block 711, the inner side of the vertical plate 706 is provided with a movable block 709, the movable block 709 is locate...

Embodiment 3

[0062] Such as Figure 10 , Figure 11 As shown, the difference from Embodiment 1 is that the fixing device includes a vertical plate 706, a first screw rod 707, a movable block 709, a first round block 711, a fixed leg 716, a pull rod 717, a spring 718, and the vertical plate 706 Set on both sides of the end of the rack 602, between the two racks 602 and the middle of the vertical plate 706, a through hole 708 is provided to facilitate the gas to pass through the vertical plate 706 and contact the tobacco on the rack 602. The vertical plate 706 is up and down Both sides are symmetrically provided with several first screw rods 707, and the vertical plate 706 is provided with threaded holes cooperating with the first screw rods 707. Movable block 709, the movable block 709 and the first screw rod 707 are located on the same axis, the first round block 711 is arranged in the cavity 712 inside the movable block 709, by rotating the first screw rod 707, the first round block 711 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com