Lithium niobate substrate clamp with liquid level detection function and proton exchange method

A technology of liquid level detection and proton exchange, which is applied in the field of integrated optics, can solve problems such as temperature fluctuations of proton exchange liquid, and achieve the effect of simple structure, high reliability, and simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only examples and not intended to limit the present application.

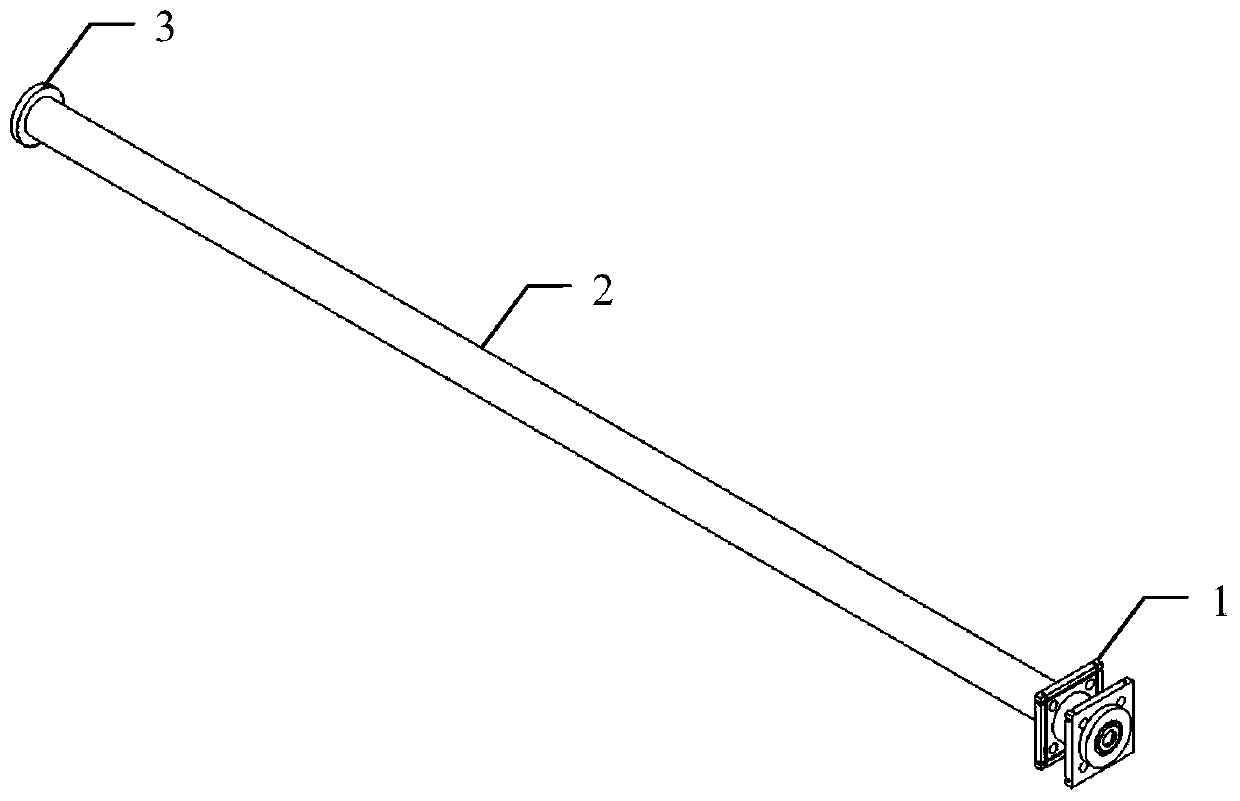

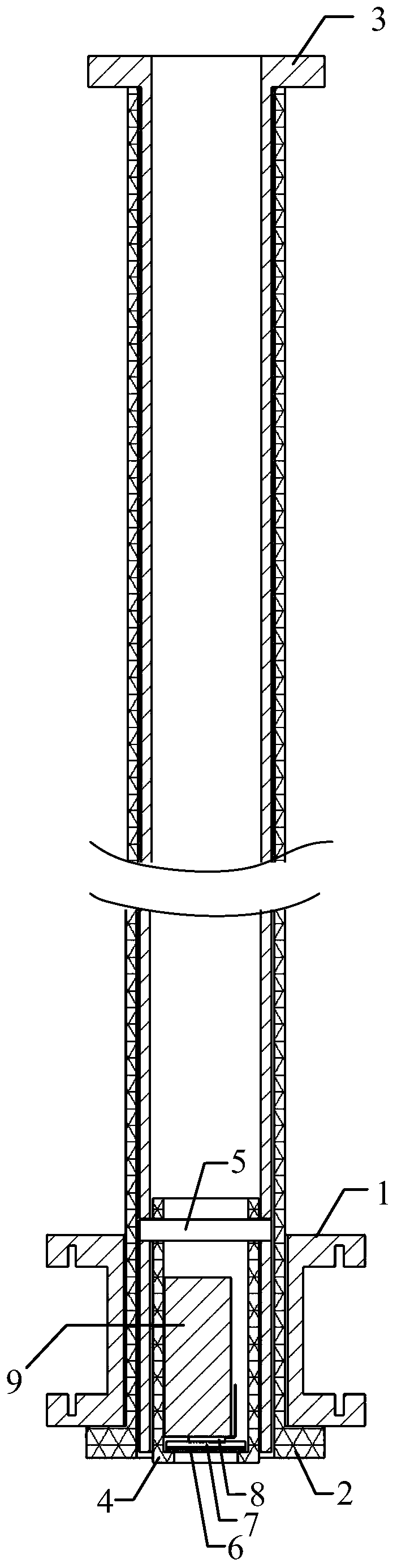

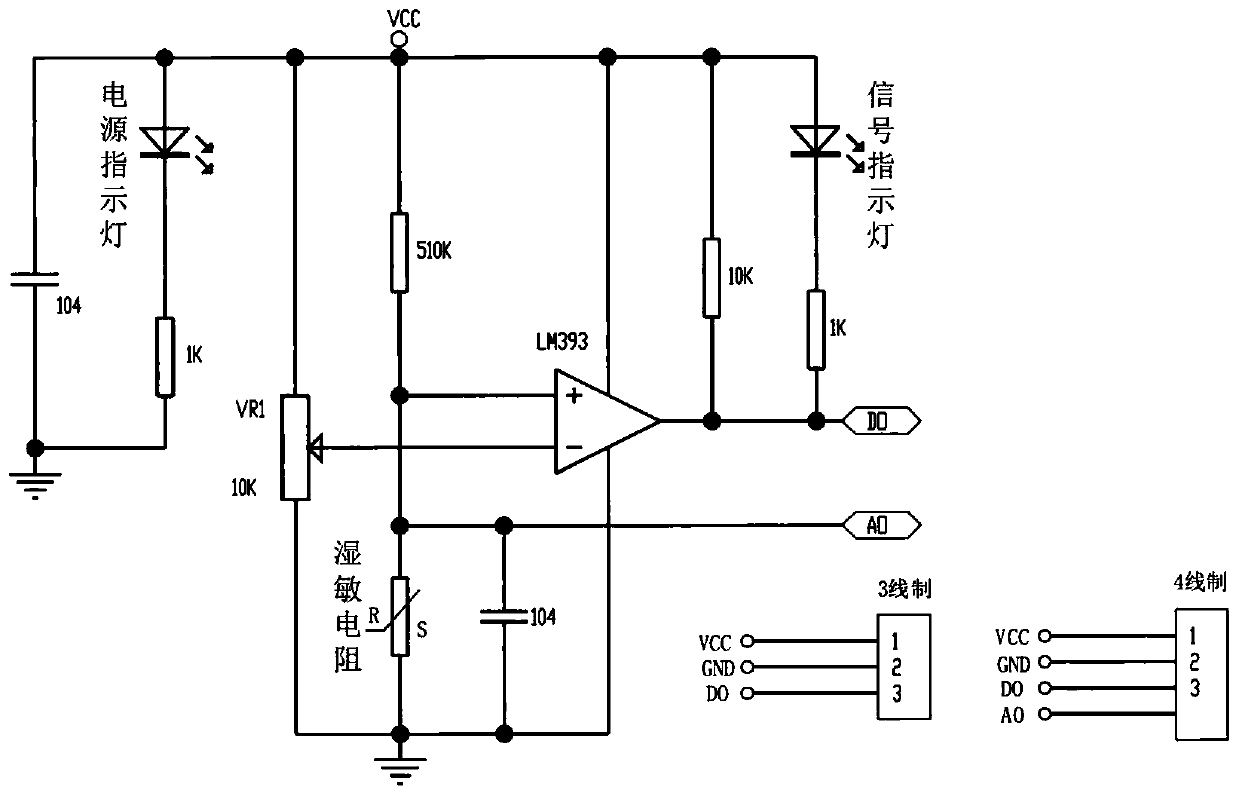

[0035] A lithium niobate substrate fixture with a liquid level detection function provided by an embodiment of the present invention, such as figure 1 and figure 2 as shown, figure 2 for figure 1 The cross-sectional view includes: a lithium niobate substrate slot block 1, a hollow cylindrical slot block clamping rod 2, a hollow cylindrical sensing rod 3, and a hollow cylindrical sleeve 4 , a positioning pin 5 for fixing the sensing rod 3 and the sleeve 4, a high temperature resistant microporous ceramic filter sheet 6, a high temperature resistant water absorbent sponge 7, a humidity sensitive element 8 and a fixed block 9 located in the sleeve 4, and A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com