Device for digestion and titration of sample tube

A sample tube and titration technology, which is applied in the field of analytical chemical detection, can solve the problems of many reagents and utensils required, low efficiency in the measurement of large batches of samples, splashing of high-heat liquid in the digestion bottle, etc., and achieve the effect of improving the efficiency of sample addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

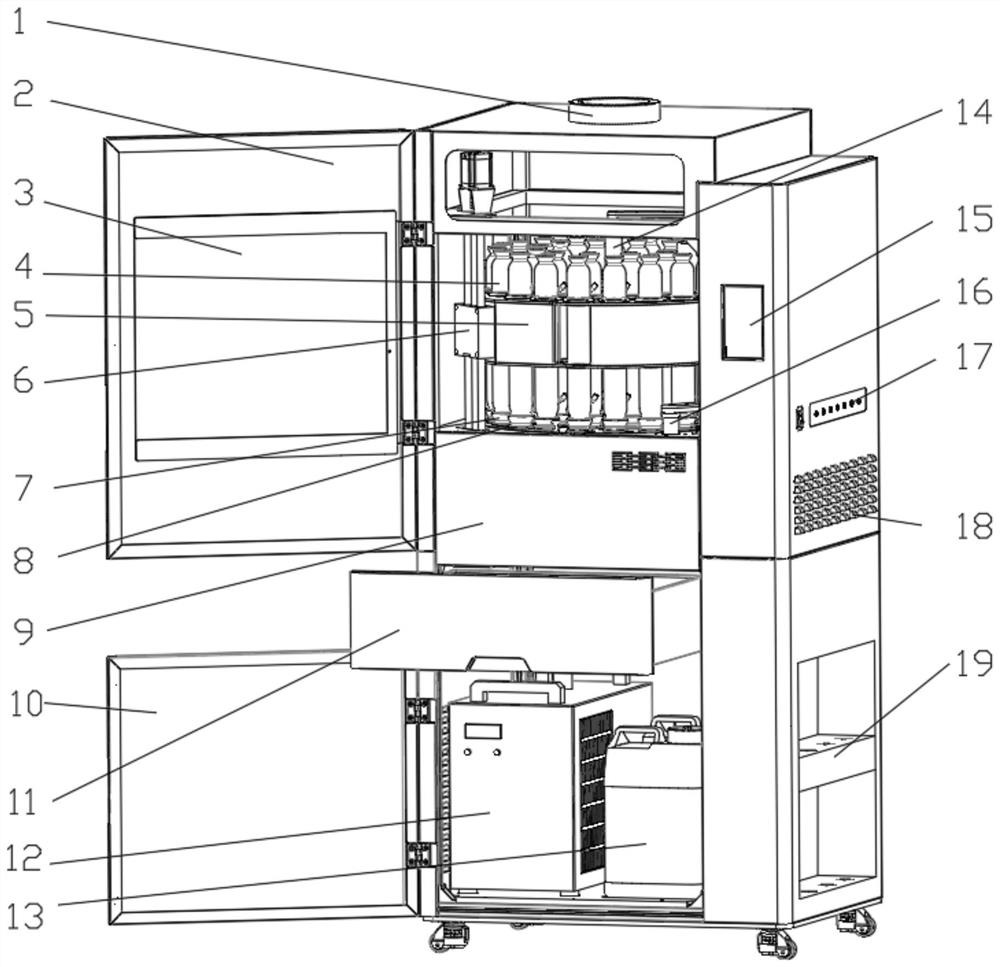

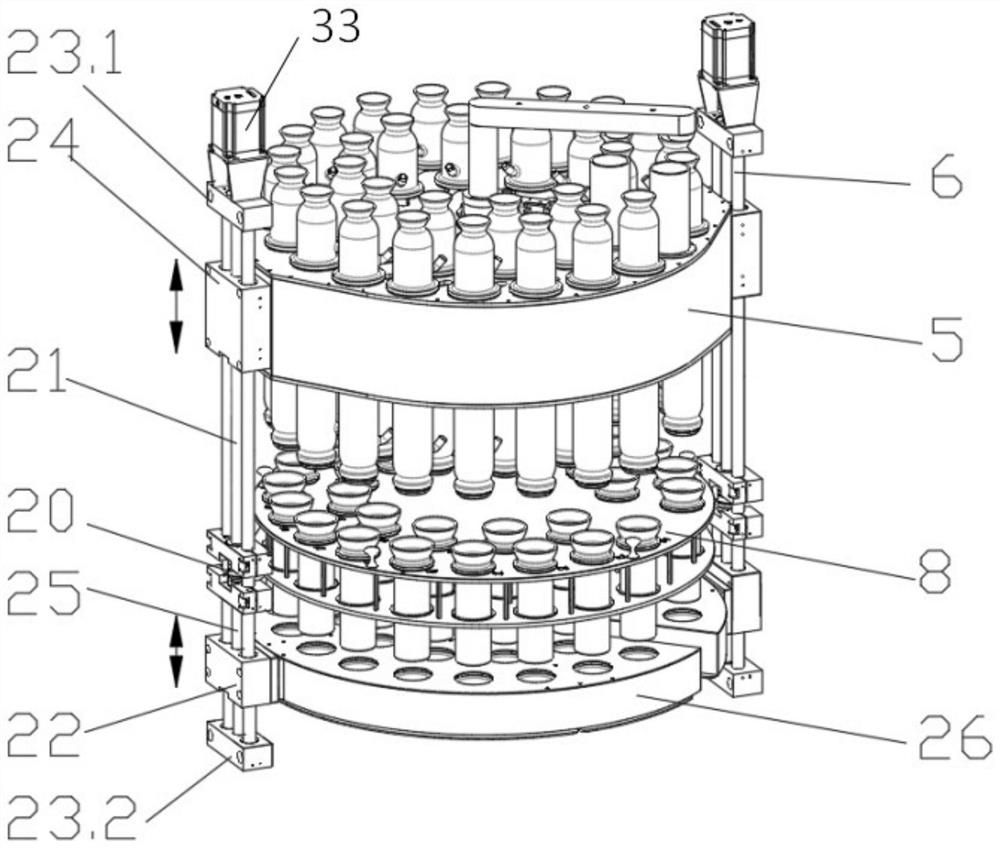

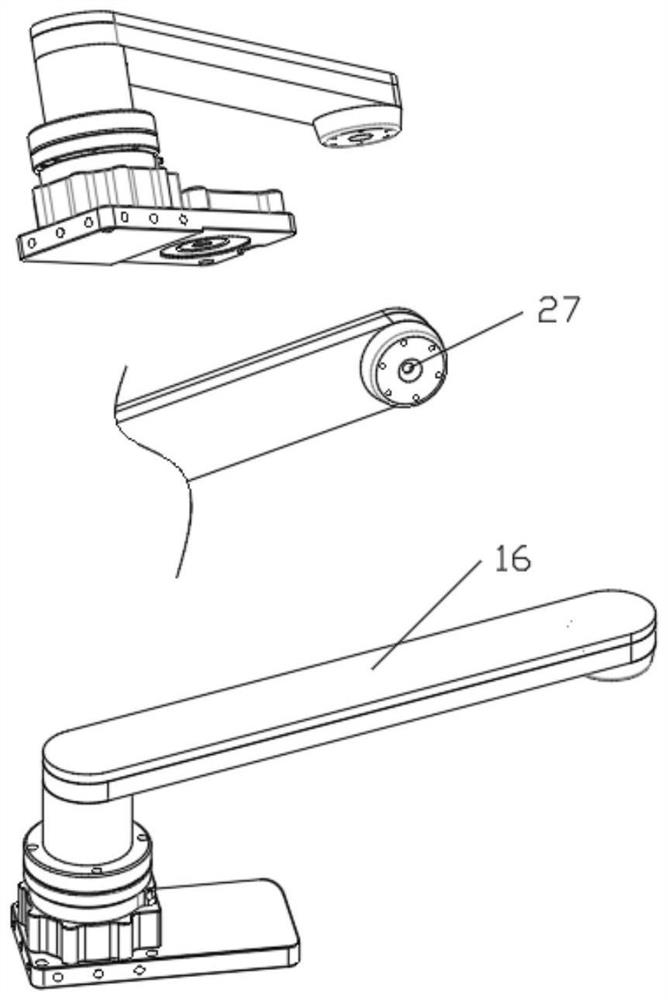

[0070] Such as Figure 1-2 A device for digestion and titration of sample tubes for COD determination as shown, comprising a condensation module (5), a heating module (26), a sample tube module, a stepper motor (33), and a linear module (6), wherein :

[0071] The condensing module (5) includes a condensing tube disc, a condensed water pipeline (not shown), and a cold water container (not shown), wherein the surface of the condensing tube disc is provided with two or more condensing tube (4) jacks; the condensing tube ( 4) The upper end is provided with a water inlet, and the lower end is provided with a water outlet, which are respectively connected to the chiller (12) through condensed water pipelines, thereby forming a cooling circuit (not shown);

[0072] The sample t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com