Water-based paint for interior walls and preparation method thereof

A water-based, interior wall technology, applied in coatings and other directions, can solve the problems of increased splash performance of coatings, low viscosity of water-based coatings, and reduced water resistance of coatings, and achieve the effects of complete film formation, increased hiding power, and enhanced hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

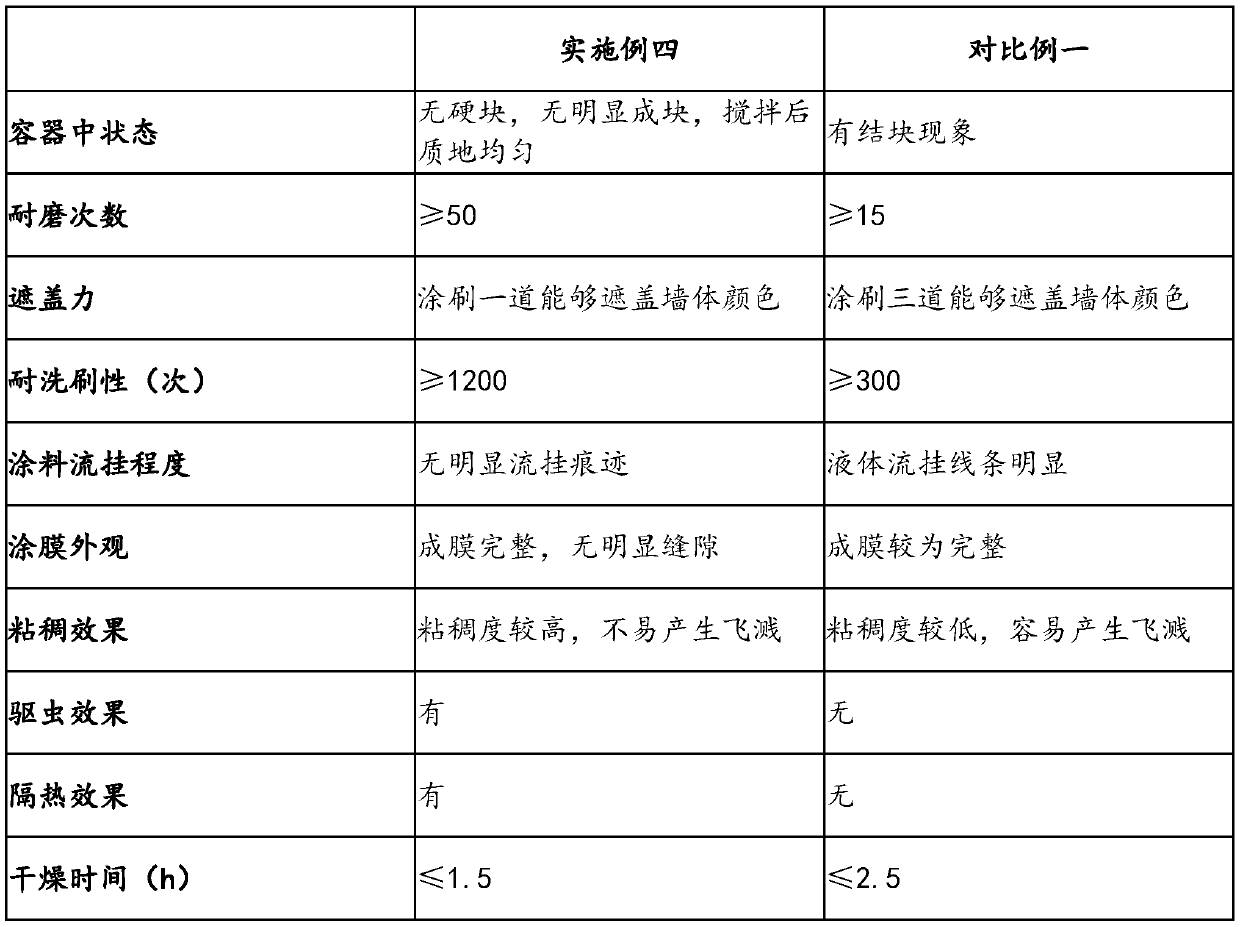

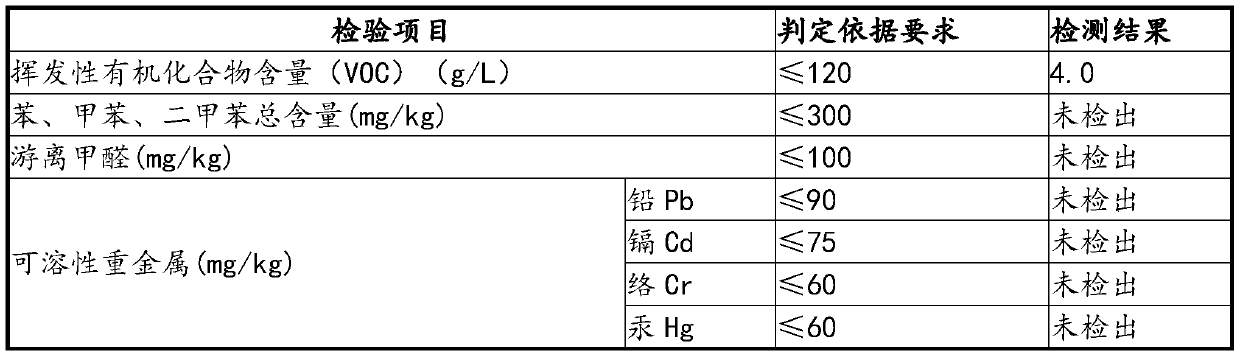

Examples

Embodiment 1

[0022] This embodiment specifically provides a water-based coating for interior walls, which includes 260-380 kg of okra mucus, 20-50 kg of hollow microspheres, 12-17 kg of dispersant, 0.5-2 kg of wetting agent, and 0.5 kg of defoamer according to the weight in kg. -2kg, shell powder 40-140kg, heavy calcium 90-120kg, calcium hydroxide 285-360kg, water-based acrylic emulsion 60-80kg, insect repellent powder 3-5kg.

[0023] Among them, the dispersant is Disperbyk-190, the defoamer is at least one of byk-024, byk-022 and surfynol DF-40, and the insect repellent powder is made by mixing mugwort powder and lavender powder at a ratio of 1:1.

Embodiment 2

[0025] This embodiment provides a kind of preparation technology of interior wall water-based paint:

[0026] Choose fresh and disease-free okra, cut it into 1cm-long pieces, soak the okra in deionized water according to the ratio of material to liquid 5:3, let it stand for 5 minutes, then knead it while stirring, repeat 3 times, when finished Filter with a 100-mesh filter to remove impurities, and obtain the treated okra mucus, which is sealed and stored at a low temperature of 3°C; 260kg of okra mucus, 12kg of dispersant, 0.5kg of wetting agent, 0.5kg of defoamer, and 40kg of shell powder , 90kg of heavy calcium, 285kg of calcium hydroxide and 3kg of insect repellent powder were put into the ball mill in sequence according to the proportion and ground evenly, the grinding time was 30min, and finally filtered through 1200 mesh screen to obtain the mixed solution; Sequentially add to the container to disperse and stir evenly, then add 20kg of hollow microspheres and mix to com...

Embodiment 3

[0028] Choose fresh and disease-free okra, cut it into 1cm long pieces, soak the okra in deionized water according to the ratio of material to liquid 3:1, let it stand for 6 minutes, then knead it while stirring, repeat 3 times, when finished Filter with a 100-mesh filter screen to remove impurities, and obtain the treated okra mucus, which is sealed and preserved at a low temperature of 5°C; 327kg okra mucus, 15kg dispersant, 1kg wetting agent, 1kg defoamer, shell powder 96kg, weight Calcium 98kg, calcium hydroxide 319kg and insect repellent powder 4kg were put into the ball mill according to the proportion and grinded evenly, the grinding time was 45min, and finally filtered through 1200 mesh gauze to obtain the mixed solution; the mixed solution and 66kg water-based acrylic emulsion were added in turn Disperse and stir evenly in the container, then add 39kg of hollow microspheres and mix to complete the production of water-based paint for interior walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com