Experimental device and method for evaluating dynamic formation of hydrates in oil and gas drilling

A technology of oil and gas drilling and experimental equipment, which is applied in the direction of measuring equipment, fuel oil testing, material inspection products, etc., can solve the problems of not considering the influence of drill pipe hydrate formation and accumulation, inability to perform comprehensive simulation, and limited simulation conditions, etc., to achieve Easy installation, stable temperature control, and the effect of reducing experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

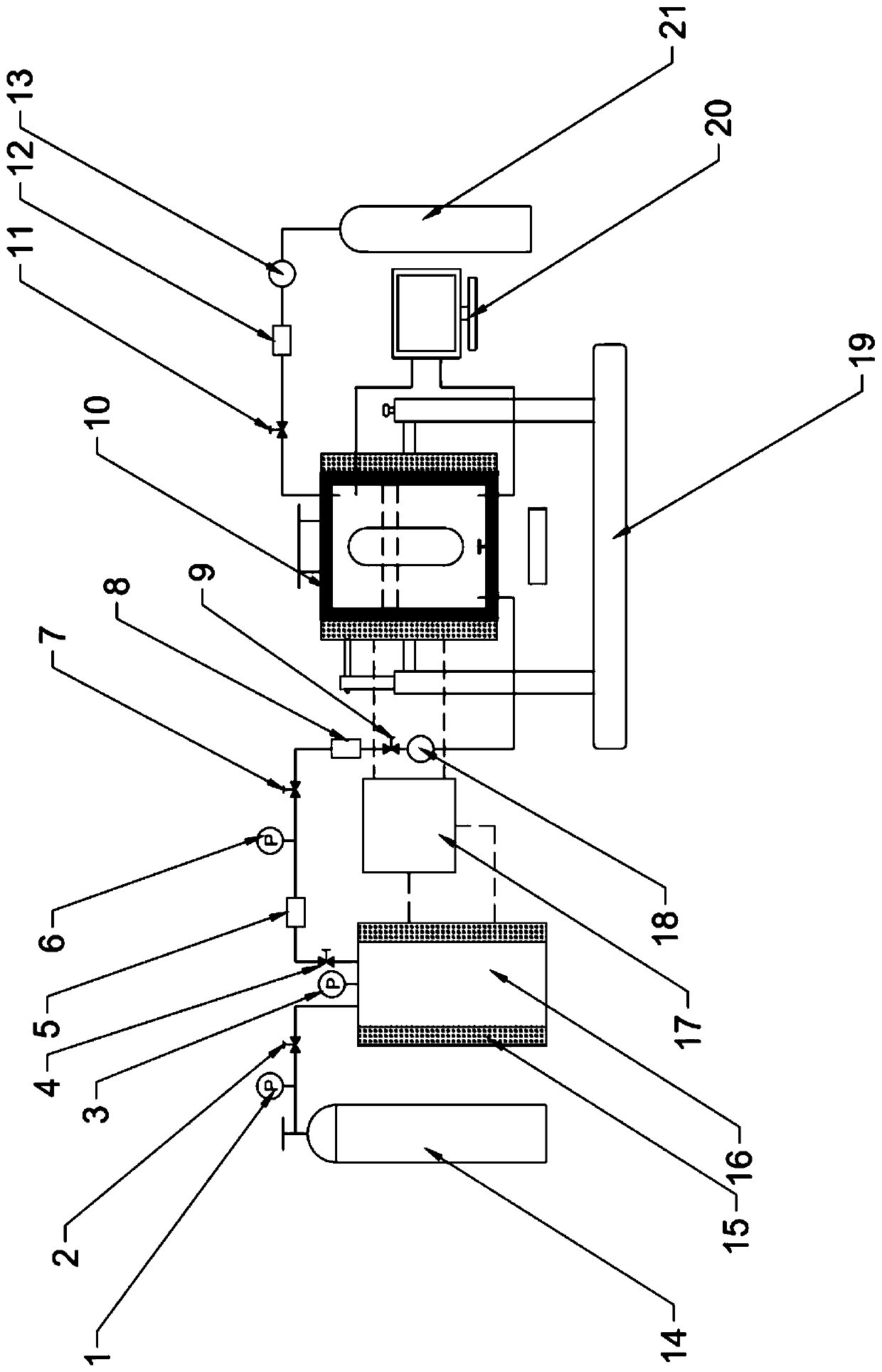

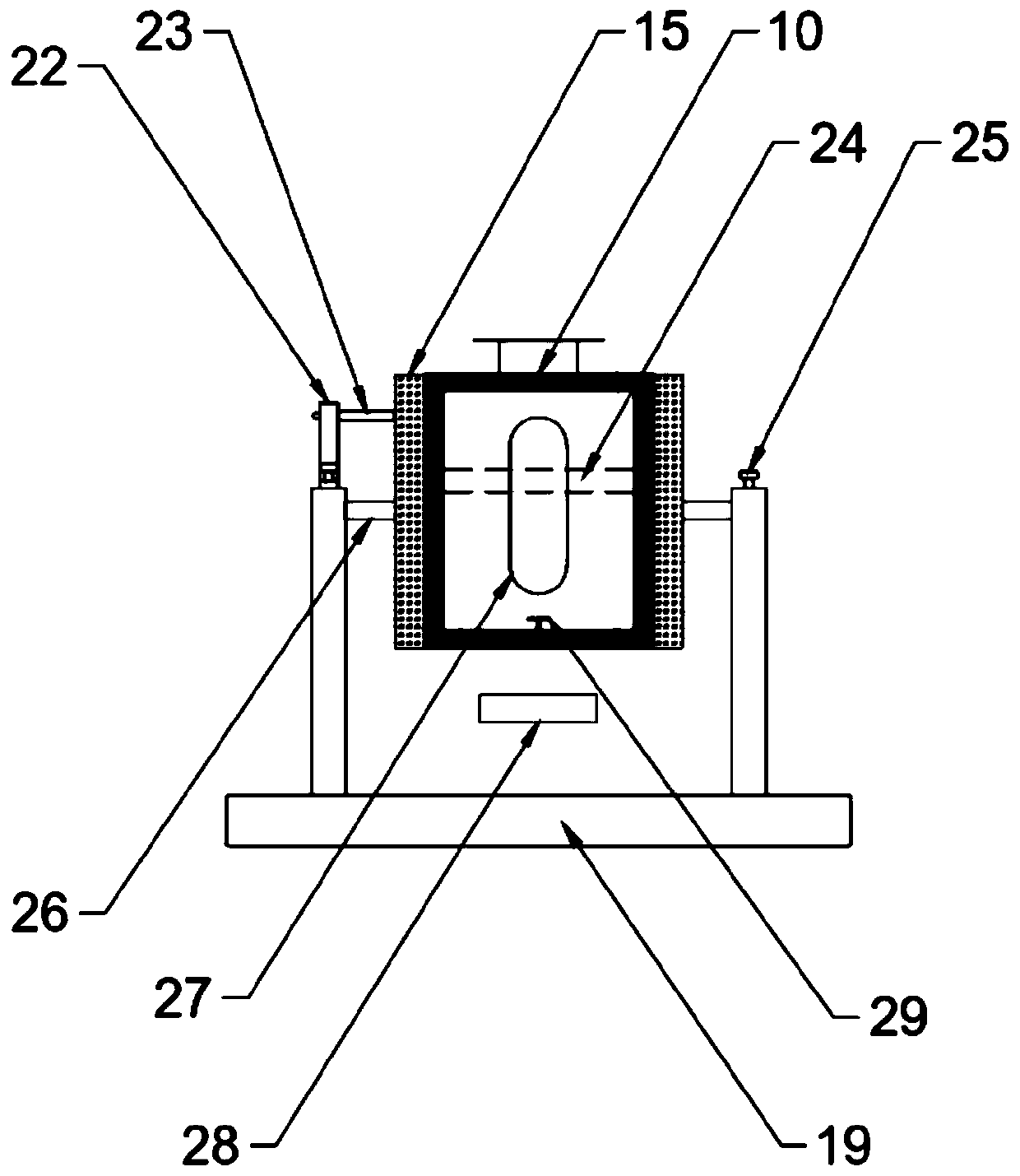

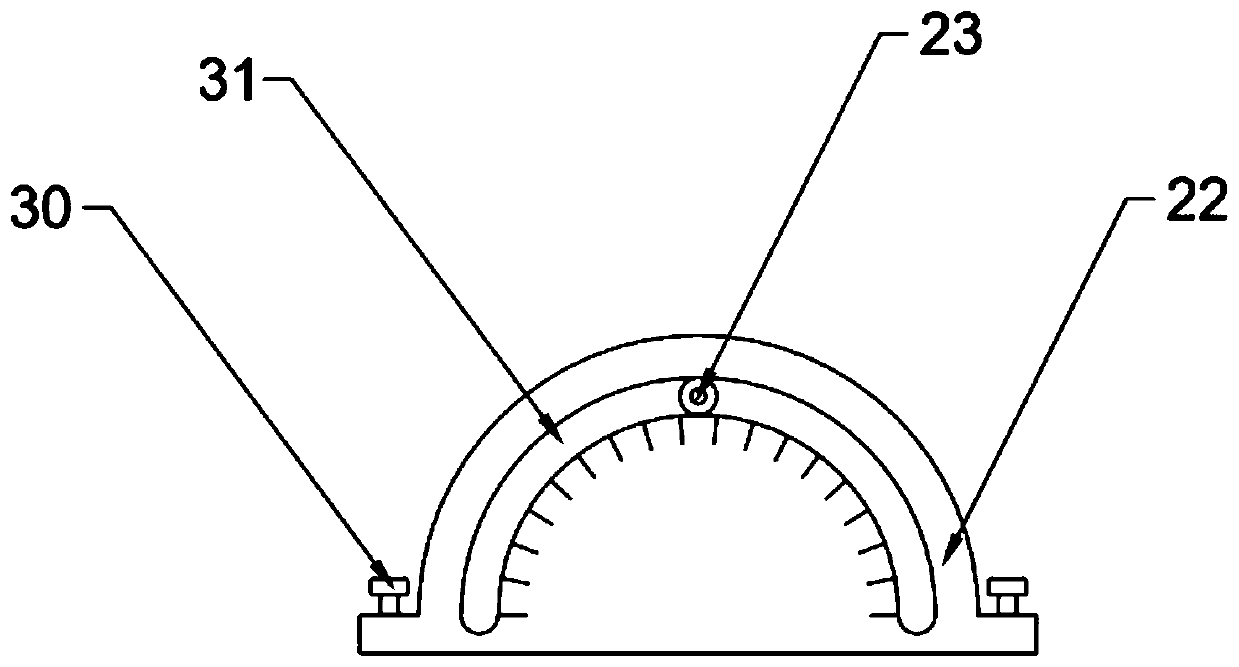

[0044] see Figure 1-3 As shown, an experimental device for evaluating the dynamic formation of hydrates in oil and gas drilling includes a high-pressure reactor 10, pressure control equipment, temperature control equipment, and data acquisition equipment. The central part of the high-pressure reactor 10 is provided with a visualization window 27, and sealing gaskets are arranged on both sides of the visualization window 27. Through the visualization window 27, the experimental situation in the high-temperature reactor 10 can be observed in real time. Block 24; the said spacer block 24 is installed and adjusted in height by a push rod, and the push rod is fixed in the high-pressure reactor 10, and the push rod is a telescopic rod, and the length of the push rod is changed to adjust the spacer block 24 to be in the high-pressure reactor 10 The height of the spacer block 24 is set with a sealing ring on the side wall, and the spacer block 24 is sealed with the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com