Combined fermentation process of edible fungus polysaccharide Pu'er tea

A technology of combining fermentation and edible fungi, applied in the fields of fermentation industry and food industry, can solve the problems of difficulty in realizing pure-bred fermentation of tea, difficulty in avoiding the harm of miscellaneous bacteria, and difficulty in realizing artificial inoculation of Pu-erh tea in solid-state fermentation, and achieves obvious practicality and efficiency. Economical, easy to mass-produce, and easy to control the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

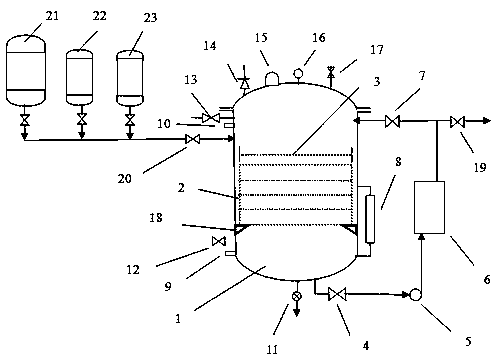

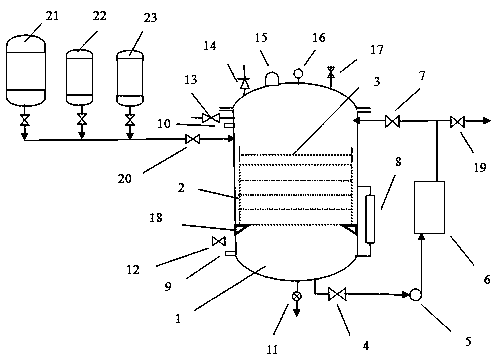

[0037] Such as figure 1 The shown Pu'er tea combined fermentation device specifically includes a main fermentation tank 1, a flower basket 2, a material liquid distribution screen 3, an intermediate valve 4, a circulating pump 5, a plate heat exchanger 6, a liquid addition valve 7, and a liquid level gauge 8. , Connect the temperature detector interface 9, connect the gas detector interface 10, exhaust valve 11, steam valve 12, intake valve 13, safety valve 14, breathing mask 15, pressure gauge 16, exhaust valve 17, support ear 18. Discharge valve 19, feed valve 20, sterile water tank 21, edible fungus fermentation tank 22, Pu'er tea strain fermentation tank 23, connecting pipes and instruments. The sealing and locking type of the tank cover of the main fermentation tank 1 and the tank body adopts a self-locking wedge engagement method, which is convenient to open. One or several loading flower baskets can be placed inside the main fermentation tank. The loading flower baskets ...

Embodiment 2

[0045] According to Example 1 fermentation device.

[0046] The specific process operation steps are different from Example 1:

[0047] Step 3: Continue to inject steam through the steam valve 12 until the temperature in the tank reaches 80°C, keep it warm for 15 minutes for pasteurization, and turn off the steam;

[0048] Step 4: Cooling and circulating to the temperature required for fermentation of 26°C, by adjusting the temperature of the hot and cold water entering the heat exchanger to keep the circulating feed liquid at the temperature required for fermentation, and keep the feed liquid circulating;

[0049] Step 5: Open the air inlet valve 13 and introduce oxygen to make the oxygen content of the gas in the tank reach 45%, ferment for 4 days, and then input sterile air through the air inlet valve 13 to replace the gas in the tank, so that the gas composition in the tank remains the same as the air composition Same, 4 days of fermentation. The above process controls the ferment...

Embodiment 3

[0051] According to the fermentation device of Example 1. The specific process operation steps are as follows different from Example 1.

[0052] Step 3: Continue to inject steam through the steam valve 12 until the temperature in the tank reaches 85°C, keep it for 15 minutes for pasteurization, and turn off the steam;

[0053] Step 4: Cooling and circulating to the temperature required for fermentation of 32°C, by adjusting the temperature of the hot and cold water entering the heat exchanger to keep the circulating feed liquid at the temperature required for fermentation, and keep the feed liquid circulating;

[0054] Step 5: Open the intake valve 13 and introduce oxygen to make the oxygen content of the gas in the tank reach 40%, and ferment for 2 days, and then input sterile air through the intake valve to replace the gas in the tank to keep the gas composition in the tank consistent with the air composition , Fermentation for another 6 days, the above process controls the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com