A rotating electromechanical experimental device with variable system parameters

A technology of system parameters and experimental devices, applied in teaching models, instruments, educational appliances, etc., can solve the problems of single model, fixed, unable to change the structural parameters of the experimental bench, etc., to facilitate construction, ensure transmission ratio, and facilitate observation and understanding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

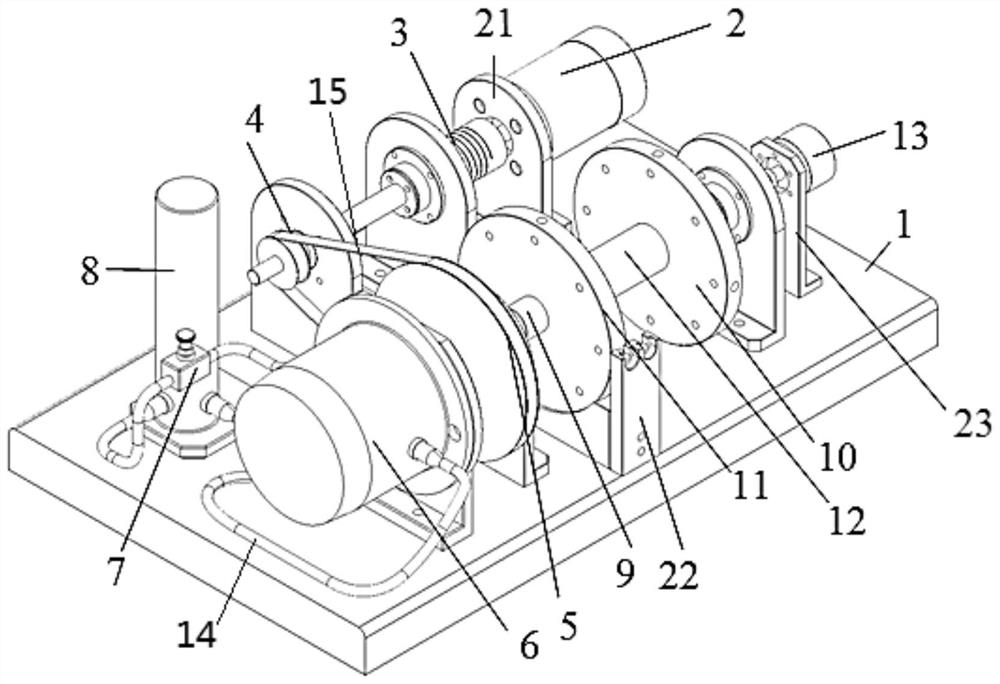

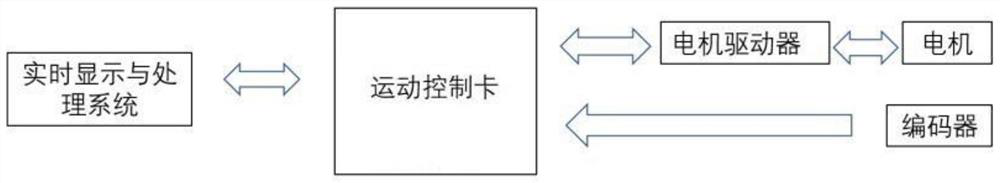

[0032] Such as figure 1 A rotary electromechanical experimental device with variable system parameters is shown, including a base 1 and a motor 2 installed on the base 1, a drive shaft 3, a deceleration system, and a rotating shaft 12; the deceleration system includes a driving wheel 4, Driven wheel 5 and driving belt 15. The motor 2 is connected with the motor driver, the motor driver is connected with the motion control card, and the motion control card is connected with the computer and the encoder 13.

[0033] The axes of the drive shaft system 3 and the rotation shaft system 12 are all parallel to the base 1, the motor 2 is installed on the motor mount 21 fixedly connected to the base 1, and is connected with one end of the drive shaft system 3, the preferred direct drive motor of the motor 2, The other end of the drive shaft 3 series is equipped with a driving wheel 4, which can be provided with some bearings on the driving shaft system 3 according to actual needs, and ...

Embodiment 2

[0035] The reduction system adopts a synchronous belt drive, the driving wheel 4 and the driven wheel 5 adopt transmission gears, and the transmission belt 15 adopts a synchronous belt. The central aperture of the free turntable 11 is larger than the shaft diameter of the rotating shaft system 12, and can move freely within a certain length range. The end face of the free turntable 11 is provided with a number of through holes. The free turntable 11 adopts a two-lobed structure. After the splicing sleeve is set on the rotating shaft system 12, the free turntable 11 and the fixed turntable 10 are connected into a whole through connecting parts such as screws, bolts and nuts, so that the free turntable 11 can be fixed with the fixed turntable 10 and rotate together with the drive shaft 3; When not in use, the free rotating disc 11 of the two-lobed formula is pulled down. All the other components and connections are the same as in Embodiment 1.

Embodiment 3

[0037] The reduction system adopts a gearbox, the output end of the driving shaft system 3 is connected to the input end of the gearbox, and the input end of the rotating shaft system 12 is connected to the output end of the gearbox. Different reduction ratios can be realized by selecting gearboxes with different reduction ratios. . All the other components and connections are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com