Multi-section continuous tea baking machine and control method thereof

A technology for roasting machines and tea leaves, which is applied in the direction of program control, general control system, electrical program control, etc., can solve the problems of low roasting efficiency, poor roasting effect, weak penetration ability, etc., and achieves improved conveying efficiency and uniform roasting of tea leaves. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

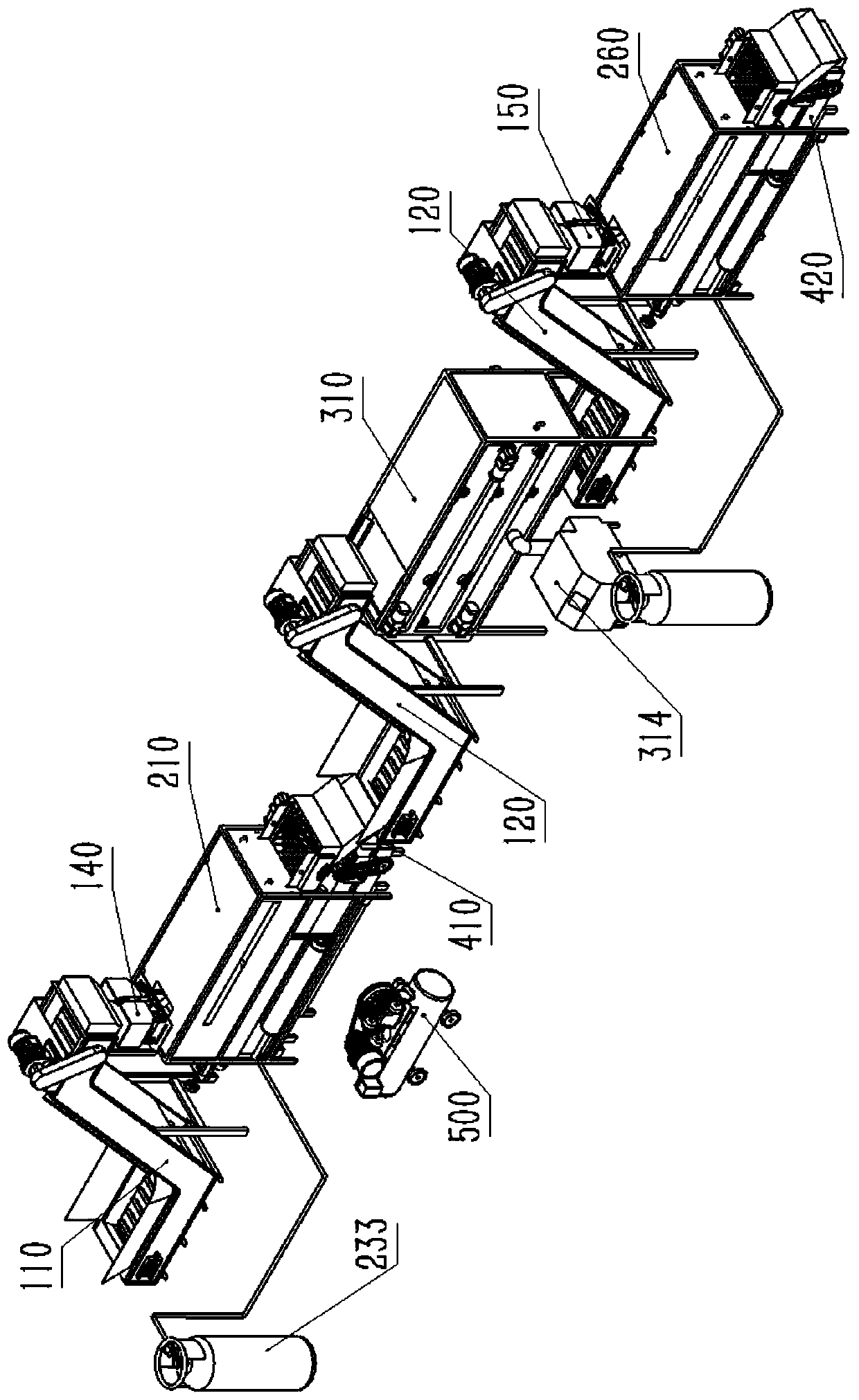

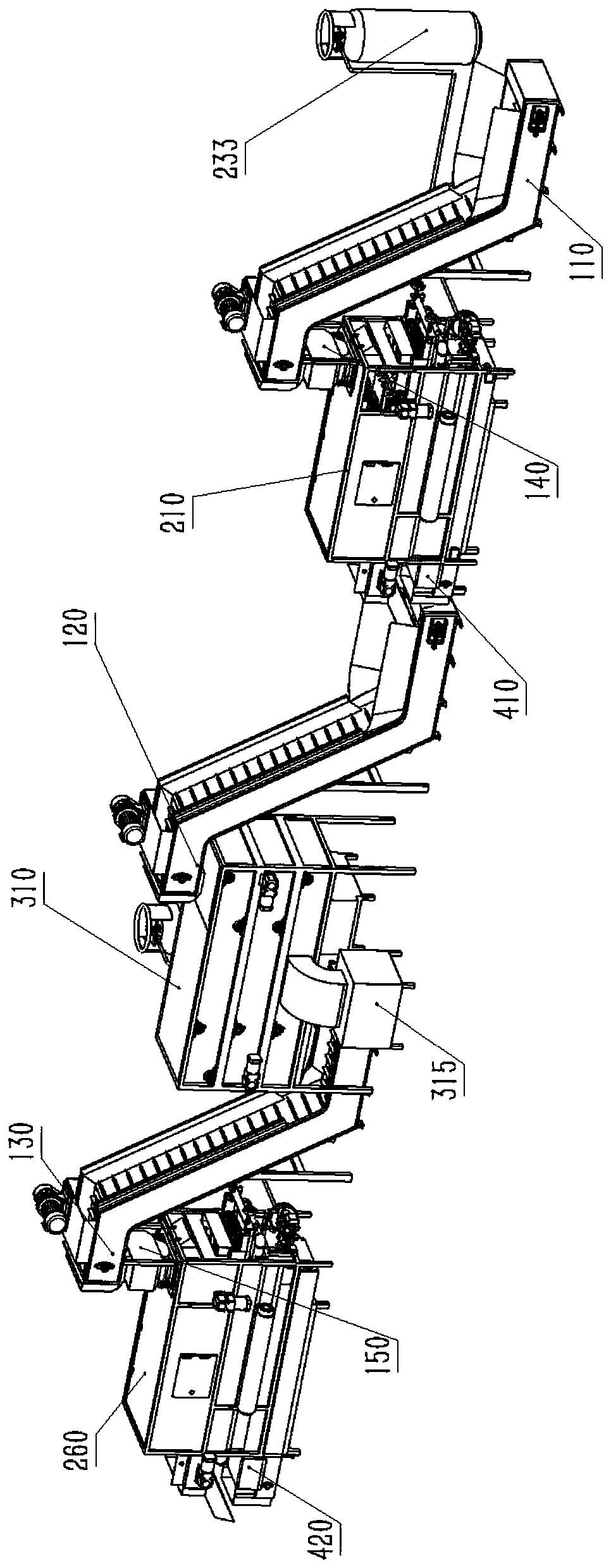

[0067] Such as figure 1 , 2 Shown: the multi-stage continuous tea roasting machine and its control method, including a PLC control unit and an initial drying feeding unit, an initial drying unit, a cooling feeding unit, a cooling unit, Re-drying feeding unit, re-drying unit;

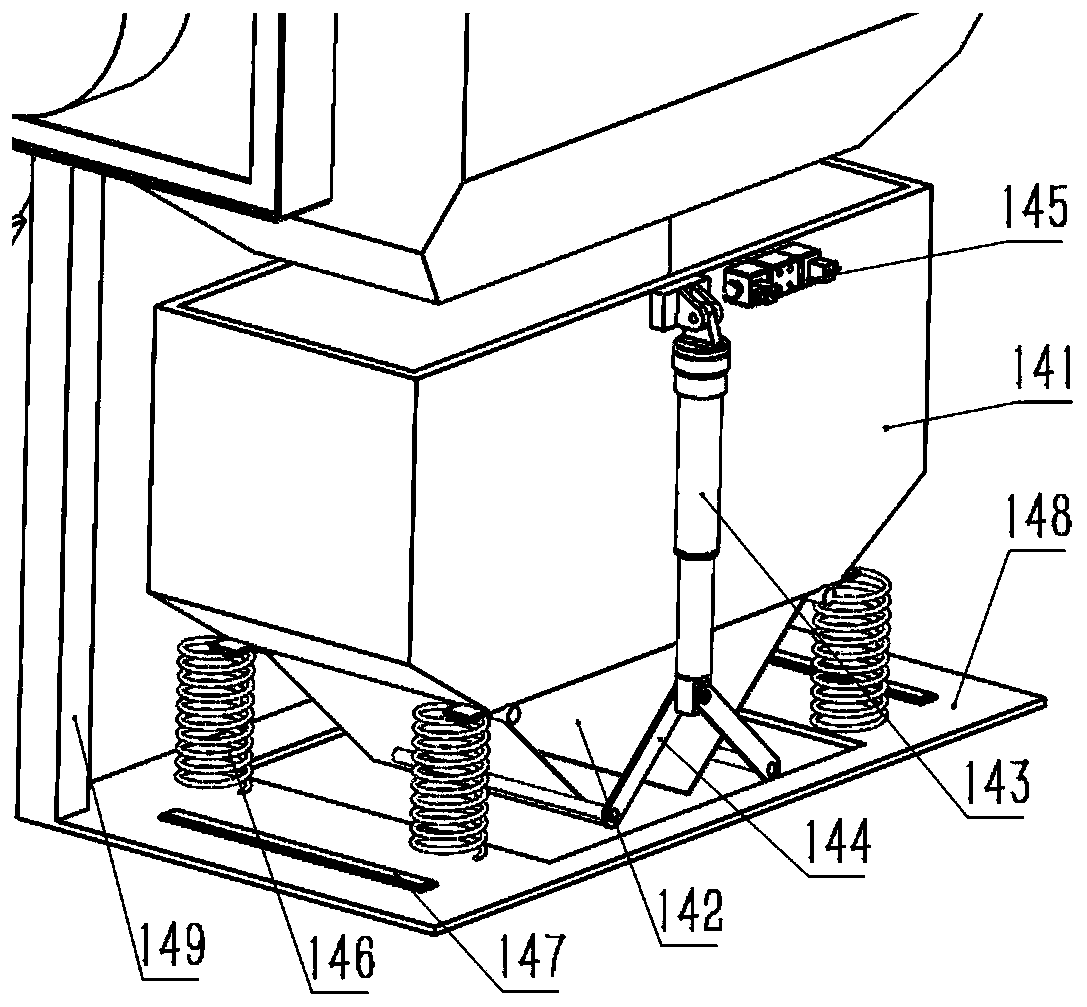

[0068] The initial drying feeding unit includes a first vertical elevator 110 and a first weighing mechanism 140 arranged in sequence for transporting tea; the initial drying unit includes a first tea roaster 210;

[0069] The cooling feeding unit includes a second vertical elevator 120; the cooling unit includes a tea cooling machine 310;

[0070] The re-drying feeding unit includes a third vertical elevator 130 and a second weighing mechanism 150 arranged in sequence for transporting tea; the re-drying unit includes a second tea roaster 260;

[0071] The top of the tea conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com