A new type of automatic stroke unloading valve assembly

A technology of automatic stroke and unloading valve, which is applied in the direction of fluid pressure actuator, servo motor assembly, fluid steering mechanism, etc. It can solve the problems of inability to accurately guarantee the coaxiality of both ends, troublesome maintenance of unloading mechanism, and high maintenance cost. problems, to achieve the effect of promoting reliability, reducing maintenance costs, and reducing maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

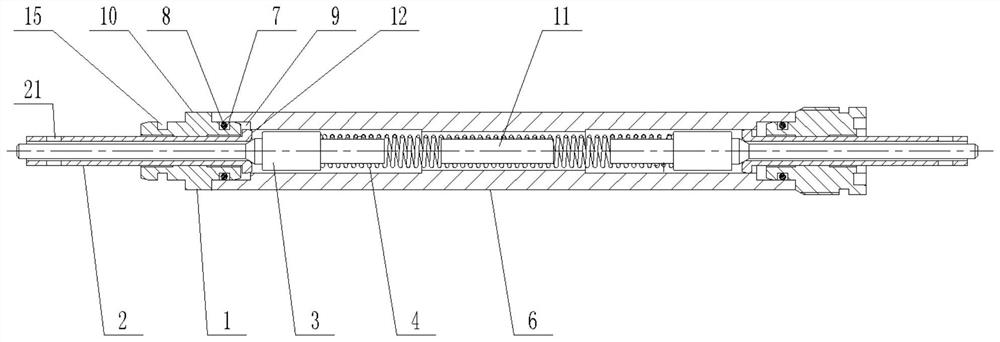

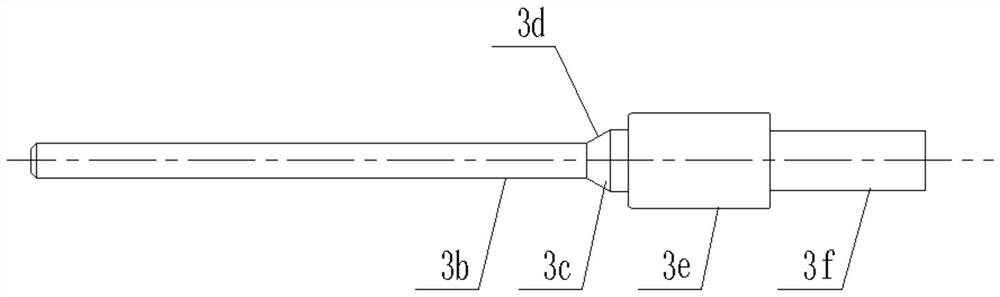

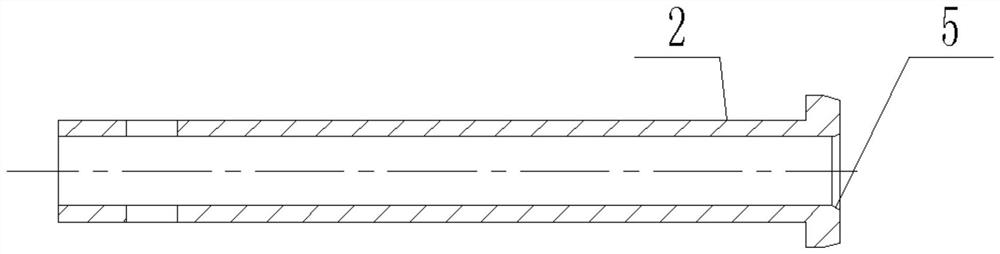

[0035] Such as Figure 1-Figure 3 As shown, a new type of automatic stroke unloading valve assembly of the present invention includes a valve tube 6 coaxial with each other, a pressure spring 4 and an unloading valve mechanism, and the unloading valve mechanism includes a sleeve seat 1 coaxial with each other, The limit sleeve 2 and the valve stem 3, wherein the sleeve seat 1 is fixed on one end of the valve tube 6, and the sleeve seat 1 is sleeved on the limit sleeve 2 and has an interference fit with the limit sleeve 2 ; One end of the limit sleeve 2 away from the center point of the valve tube 6 passes through the center hole of the sleeve seat 1, and a tapered hole is provided on the center hole of the limit sleeve 2 near the center point of the valve tube 6 5; the valve stem 3 includes a coaxial long rod 3b and a matching shaft 3c which are sequentially connected and coaxial. The matching shaft 3c is in the shape of a truncated cone, and its small-diameter end is connecte...

Embodiment 2

[0042] This embodiment is based on Embodiment 1, and further implements the description of the structure of the valve stem 3 .

[0043] Such as figure 2 As shown, in the present invention, a limiting shaft 3e is provided at the large diameter end of the matching shaft 3c, the axis of the limiting shaft 3e is collinear with the axis of the matching shaft 3c, and one end thereof is connected to the matching shaft 3c, and The limit shaft 3e is in interference fit with the center hole of the limit sleeve 2;

[0044] Both ends of the pressure spring 4 are respectively in contact with the end faces of a limiting shaft 3e.

[0045] Since the connection between the inside of the installation hole and the oil chamber where the rack piston is located is controlled by whether the conical surface on the unloading valve stem contacts the conical surface on the limit spring sleeve, and the long rod on the unloading valve stem There is a clearance fit between the position and the limit sp...

Embodiment 3

[0050] This embodiment is based on the embodiment 1, and is further described for the cooperation structure between the valve tube 6 and the sleeve seat 1 .

[0051] Such as Figure 1-Figure 3 As shown, in the present invention, an annular groove A7 is provided on the side wall of the sleeve seat 1 close to the valve tube 6, and the axis of the annular groove A7 coincides with the axis of the sleeve seat 1. The sealing ring A8 is set in A7, and the end close to the valve tube 6 on the side wall of the limit sleeve 2 is inserted into the central hole of the valve tube 6, and the inner and outer rings of the sealing ring A8 are connected with the groove of the annular groove A7 respectively. The bottom and the central hole of the valve pipe 6 are interference fit.

[0052] The annular groove A7 is preferably a rectangular groove, and the sealing ring A8 is preferably an O-shaped rubber sealing ring.

[0053] Further, both ends of the center hole of the valve tube 6 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com