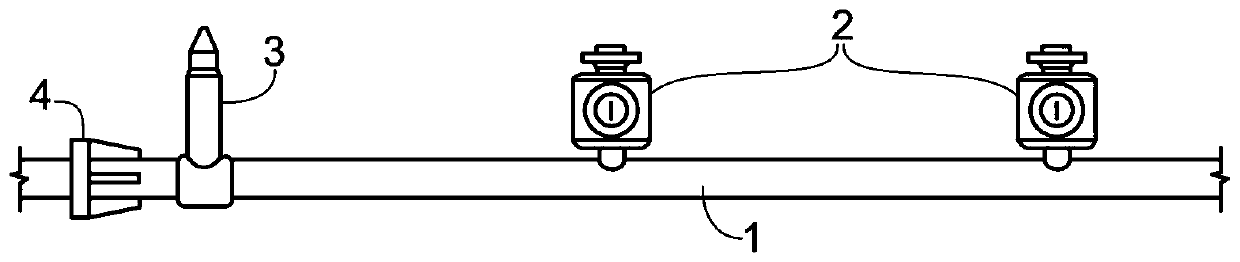

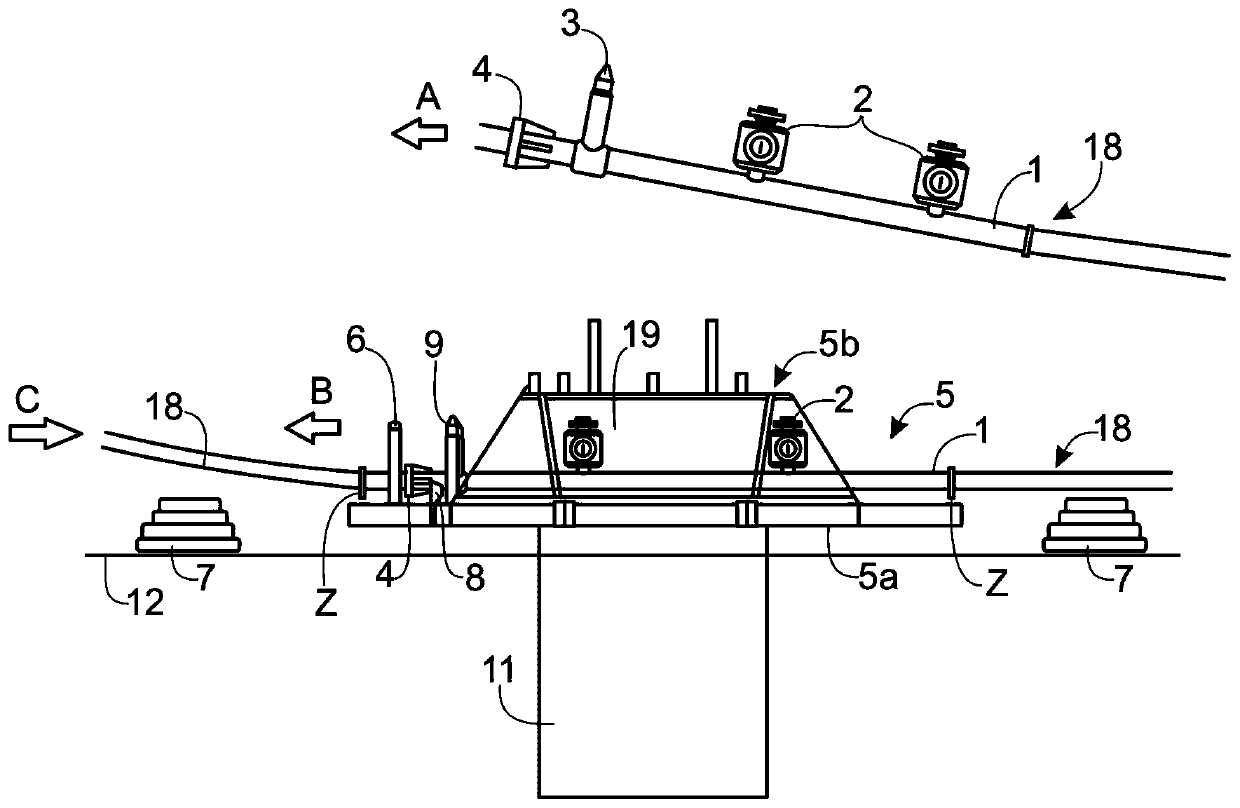

Tie-in of subsea pipeline

A technology for pipelines and underwater structures, applied in the field of underwater systems, underwater components, installation of manifolds and underwater devices, installation of main pipe joints, can solve problems such as high costs, and achieve cost reduction, less hydraulic power and communication connections , Improve the effect of ship operation planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

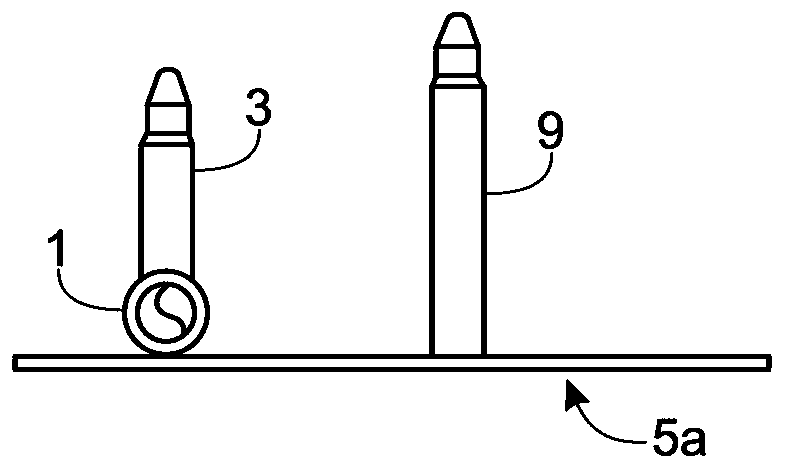

[0177] For ease of understanding, like reference numerals are used to identify like structural features in various embodiments.

[0178] Where reference is made to "pipe" in the embodiments described below, it means pipes known to those skilled in the art as "rigid pipes". Figure 24 An example of such a rigid conduit 70 is illustrated in . Such rigid piping 70 typically includes an outer insulating jacket 72 with a corrosion resistant coating 71 surrounding the finished piping 73 . Finished piping 73 is generally metal piping, usually stainless steel or carbon steel. Such rigid piping is typically manufactured in 12m sections (pipe lengths) which are welded together. Although such conduits are considered rigid conduits, it will be well understood by the skilled artisan that they need not be perfectly rigid. They generally have a small amount of elastic compliance so that they can be bent a small amount, but if the tube is pushed beyond that small amount of bend then the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com