Preparation method capable of controlling polyamide powder melt flow index

A melt flow index, polyamide powder technology, applied in the field of additive manufacturing, can solve the problems of low melt flow index of polyamide powder, reduced powder melt flow index, insufficient flow, etc., so as to improve mechanical properties and surface quality, improve the melt flow index, reduce the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

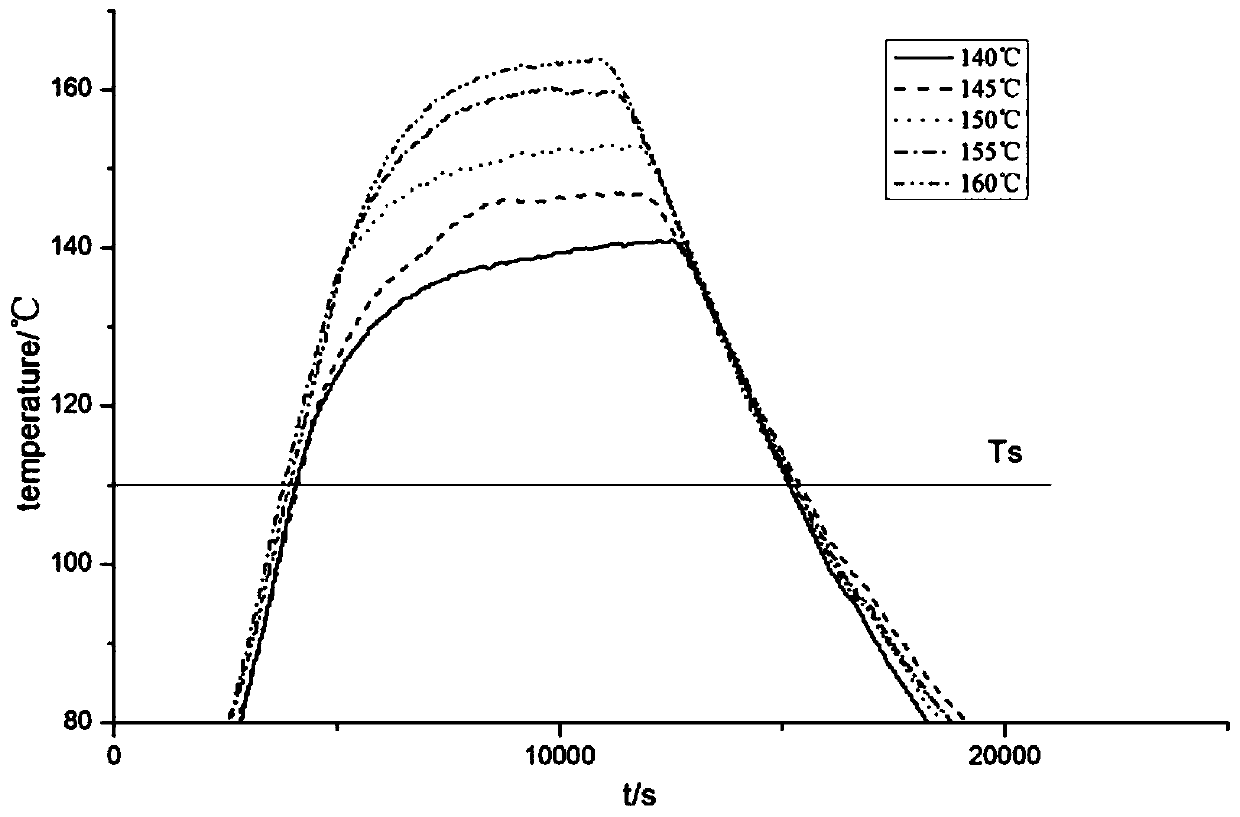

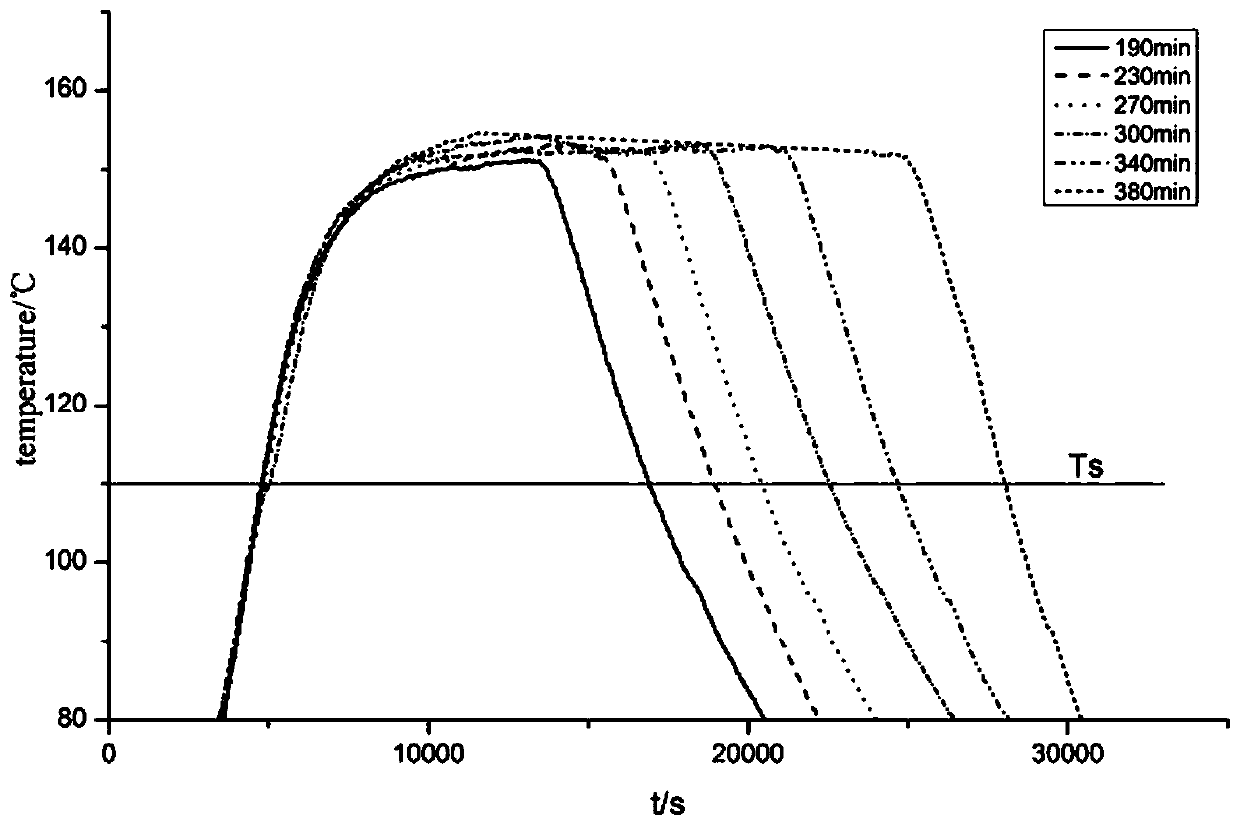

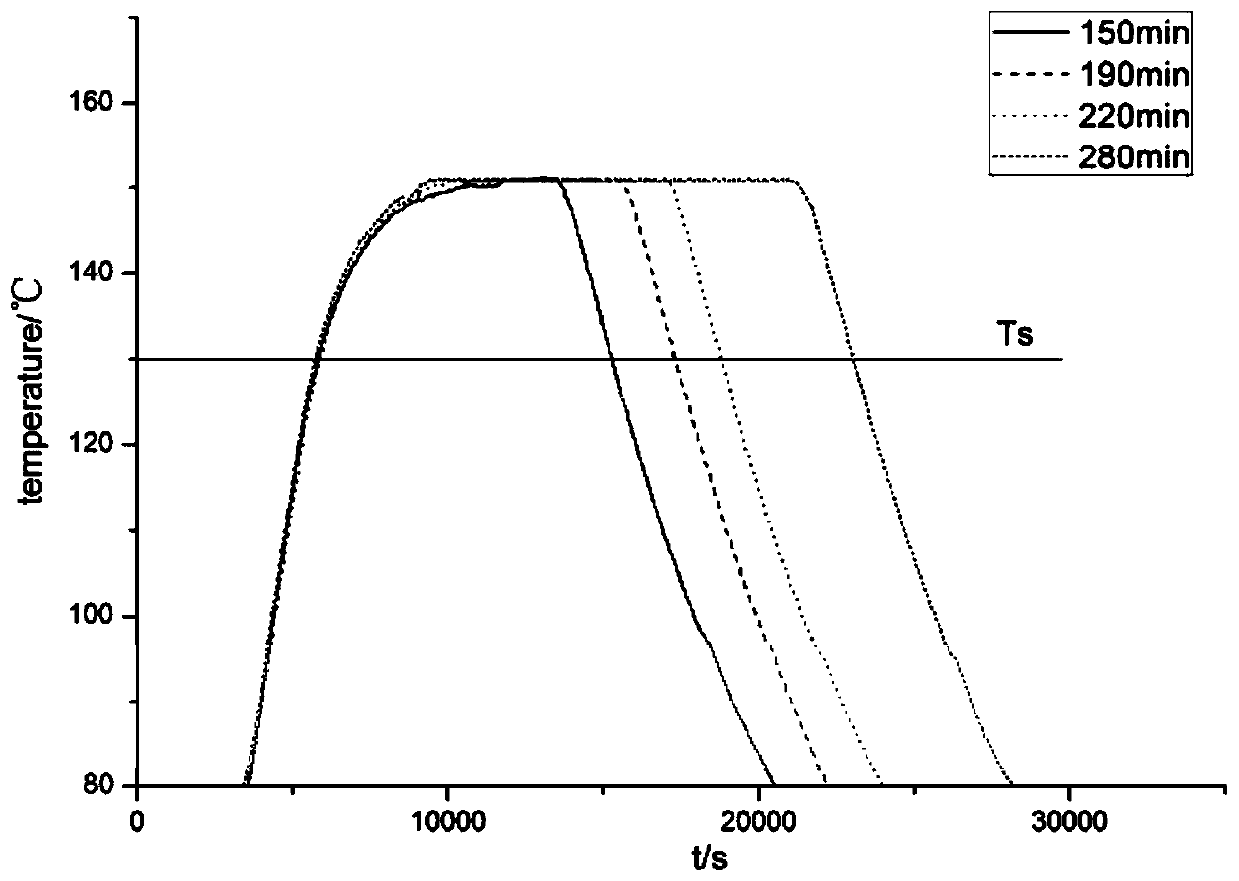

[0027] Put 4Kg of PA1212 resin and 32Kg of ethanol into a 40L reactor, feed high-purity nitrogen to a pressure of 0.3MPa, continue stirring and heat up to 110°C, at this time PA1212 resin is completely dissolved in ethanol, and then continue to heat up to a reaction temperature of 140°C ℃ and keep it warm for a certain period of time, then use cooling water to lower the temperature, so that the temperature in the kettle drops to 80℃ at an average cooling rate of 0.8℃ / min, increase the flow of cooling water to lower the temperature in the kettle to room temperature, take out the material, centrifuge and dry The PA1212 powder sample can then be obtained. During the heating and cooling process in this embodiment, the entire reaction process is kept above 110° C. for 180 minutes. Test the PA1212 powder MFR, and print the parts on the ST252 equipment of Hunan Farsoon Hi-Tech, and test the mechanical properties and surface roughness. The results are shown in Table 1, and the reaction...

Embodiment 2

[0029] Put 4Kg of PA1212 resin and 32Kg of ethanol into the 40L reaction kettle, pass high-purity nitrogen gas to the pressure of 0.3MPa, continue to stir and heat up to 110°C, at this time the PA1212 resin is completely dissolved in ethanol, and then continue to heat up to the reaction temperature of 145 ℃ and keep it warm for a certain period of time, then use cooling water to lower the temperature, so that the temperature in the kettle drops to 80℃ at an average cooling rate of 0.8℃ / min, increase the flow of cooling water to lower the temperature in the kettle to room temperature, take out the material, centrifuge and dry The PA1212 powder sample can then be obtained. During the heating and cooling process in this embodiment, the entire reaction process is kept above 110° C. for 180 minutes. Test the PA1212 powder MFR, and print the parts on the ST252 equipment of Hunan Farsoon Hi-Tech, and test the mechanical properties and surface roughness. The results are shown in Table ...

Embodiment 3

[0031] Put 4Kg of PA1212 resin and 32Kg of ethanol into a 40L reactor, feed high-purity nitrogen to a pressure of 0.3MPa, continue stirring and heat up to 110°C, at this time PA1212 resin is completely dissolved in ethanol, and then continue to heat up to a reaction temperature of 150°C ℃ and keep it warm for a certain period of time, then use cooling water to lower the temperature, so that the temperature in the kettle drops to 80℃ at an average cooling rate of 0.8℃ / min, increase the flow of cooling water to lower the temperature in the kettle to room temperature, take out the material, centrifuge and dry The PA1212 powder sample can then be obtained. During the heating and cooling process in this embodiment, the entire reaction process is kept above 110° C. for 180 minutes. Test the PA1212 powder MFR, and print the parts on the ST252 equipment of Hunan Farsoon Hi-Tech, and test the mechanical properties and surface roughness. The results are shown in Table 1, and the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com