Medium-temperature water-soluble PVA composition for melting, casting and film forming, particles and preparation method thereof

A technology of casting film forming and composition, which is applied in the field of medium temperature water-soluble PVA composition and its particles and preparation, can solve the problems of difficult melt casting film forming, poor melt fluidity, high processing cost, etc., and achieve the benefit of melting Film formation by casting method, high melt flow rate and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Second aspect, the present invention provides a kind of preparation method of the medium-temperature water-soluble PVA particle that melt casting film forms, and this method comprises:

[0050] The above steps of mixing and granulating the medium-temperature water-soluble PVA composition formed by melting and casting into a film.

[0051] In the method of the present invention, there is no particular limitation on the preparation method of the above-mentioned medium-temperature water-soluble PVA particles formed by melt casting into a film, which can be various preparation methods conventionally adopted by those skilled in the art, and will not be described again. In a specific embodiment of the present invention, it is prepared according to the following steps:

[0052] (1) Stir all the compositions described in a high-speed mixer at room temperature for 5-20 minutes;

[0053] (2) Use parallel twin-screw granulator to extrude and granulate to obtain medium-temperature...

Embodiment 1

[0064] A medium-temperature water-soluble PVA composition formed by melt casting into a film, comprising:

[0065] 100 parts by weight of PVA1788, 25 parts by weight of sorbitol, 2 parts by weight of organic tin heat stabilizer, 2 parts by weight of aluminum distearate, 10102 parts by weight of antioxidant, 1 part by weight of DSTP, 2 parts by weight of polyethylene wax, SHP-601 Parts by weight, 1 part by weight of cocamidopropyl hydroxysultaine.

Embodiment 2

[0067] A medium-temperature water-soluble PVA composition formed by melt casting into a film, comprising:

[0068] 100 parts by weight of PVA2088, 15 parts by weight of ethylene glycol, 20 parts by weight of glycerin, 2 parts by weight of rare earth heat stabilizer, 3 parts by weight of barium stearate, 6973 parts by weight of antioxidant, 1680.5 parts by weight, 2 parts by weight of pentaerythritol stearate 1.5 parts by weight of SHP-50, 1.5 parts by weight of cocamidopropyl betaine.

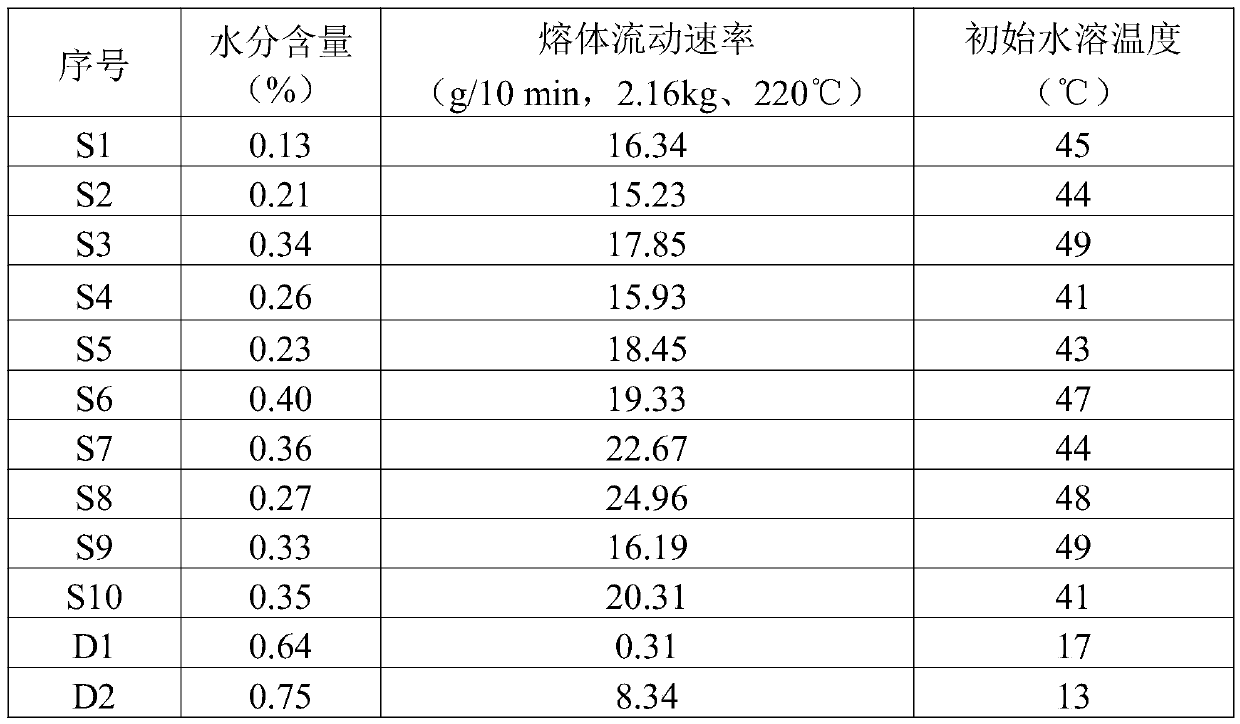

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com