Sulfide solid electrolyte and preparation method thereof, and all-solid-state battery

A technology of sulfide electrolyte and solid electrolyte, applied in electrolytes, secondary batteries, circuits, etc., can solve the problems of poor ionic conductivity, weak performance of high-voltage-resistant positive electrode materials, and insignificant effects, and achieve excellent electrical performance, high Good ionic conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

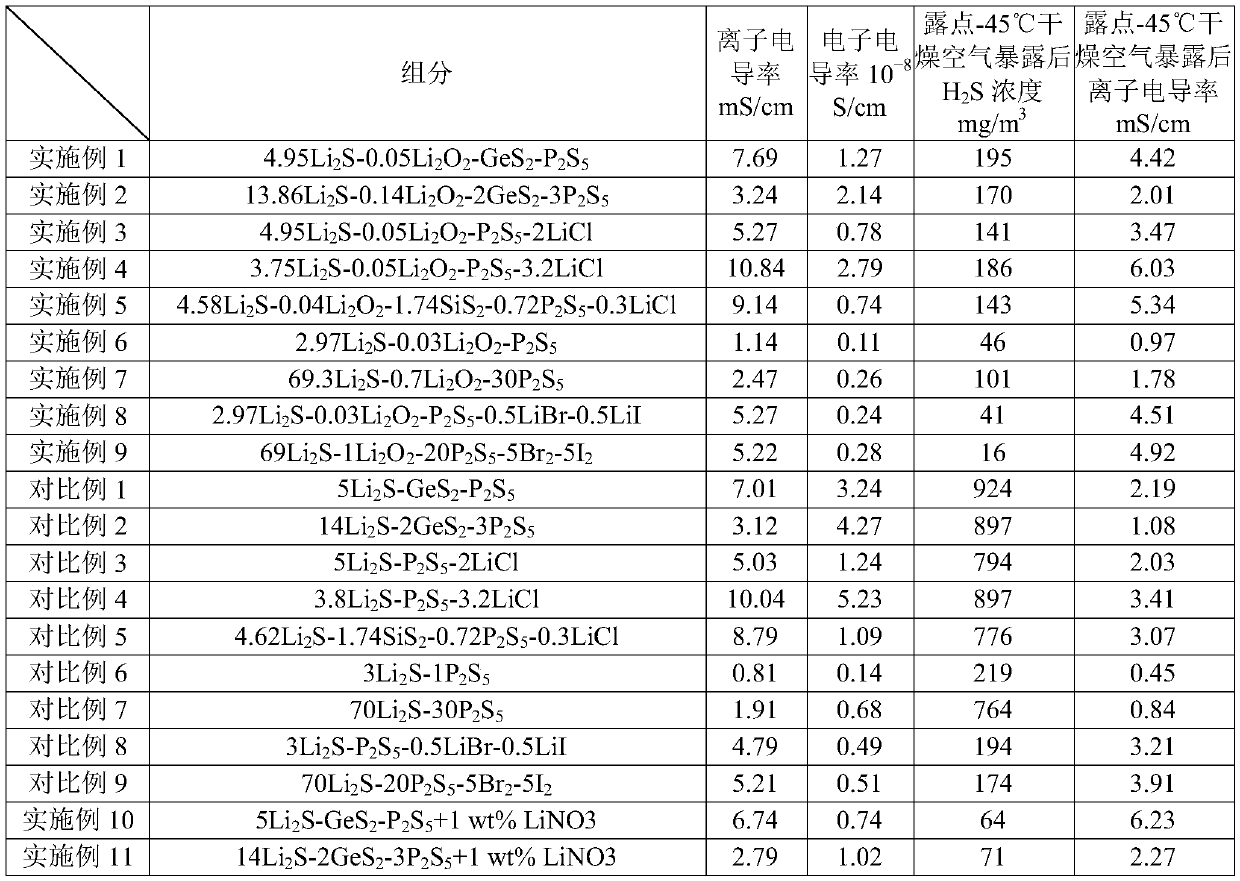

Embodiment 1

[0046] A kind of sulfide solid electrolyte, the component is 4.95Li 2 S-0.05Li 2 o 2 -GeS 2 -P 2 S 5 (i.e. Li 2 o 2 Incorporate Li 10 GeP 2 S 12 Replace part of Li 2 S), its preparation method comprises the following steps:

[0047] 19.3145g of Li 2 S, 0.1948g of Li 2 o 2 , 11.6148g of GeS 2 , 18.8759g of P 2 S 5 The raw materials were mixed, placed in a 500 mL roller mill jar, 400 g of 10 mm yttrium stabilized zirconia grinding beads were added, and ground at 150 rpm for 24 hours until uniformly mixed to obtain a precursor. Take 2g of the precursor and press it into tablets, put ten pieces into a quartz tube with an inner diameter of 25mm and a length of 300mm, seal it, and calcinate it at 680°C for 20min, and grind the calcined block into powder to obtain a sulfide solid electrolyte powder.

Embodiment 2

[0049] A kind of sulfide solid electrolyte, the component is 13.86Li 2 S-0.14Li 2 o 2 -2 GeS 2 -3P 2 S 5 (i.e. Li 2 o 2 Incorporate Li 3.25 Ge 0.25 P 0.75 S 4 replace part L i 2S), its preparation method comprises the following steps:

[0050] 20.1068g of Li 2 S, 0.2028g of Li 2 o 2 , 8.6366g GeS 2 , 21.0538g of P 2 S 5The raw materials were mixed, placed in a 500 mL roller mill jar, 400 g of 10 mm yttrium stabilized zirconia grinding beads were added, and ground at 150 rpm for 24 hours until uniformly mixed to obtain a precursor. Take 2g of the precursor and press it into tablets, put ten pieces in a quartz tube with an inner diameter of 25mm and a length of 300mm, seal it, and calcinate at 520°C for 4h, and grind the calcined block into powder to obtain a sulfide solid electrolyte powder.

Embodiment 3

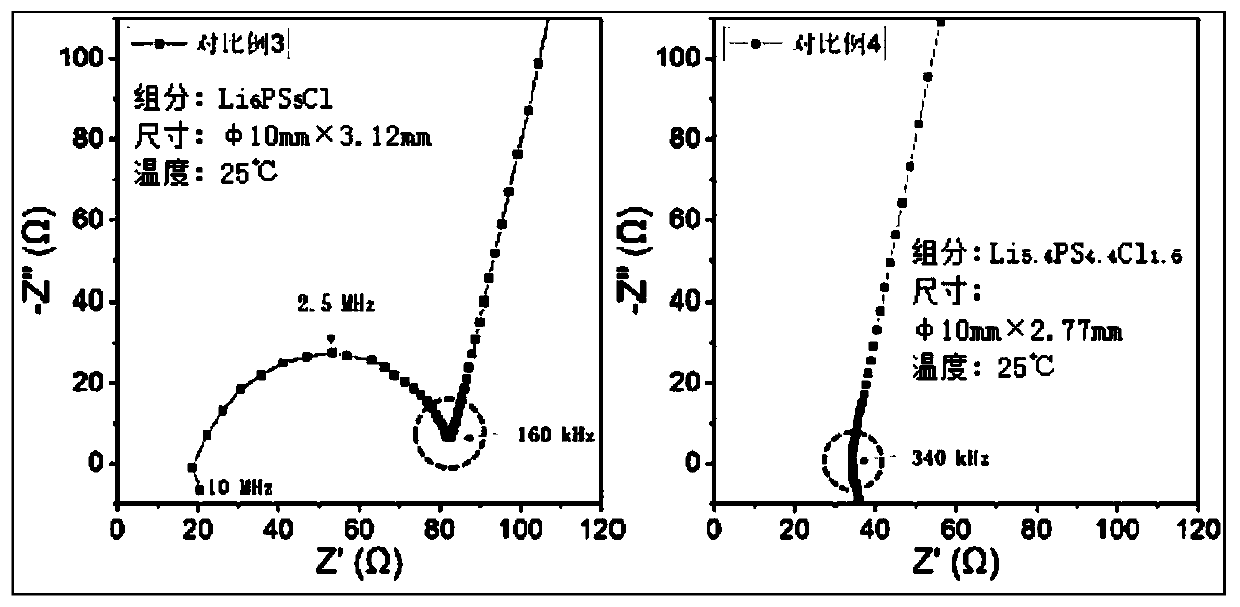

[0052] A kind of sulfide solid electrolyte, the component is 4.95Li 2 S-0.05Li 2 o 2 -P 2 S 5 -2LiCl (ie Li 2 o 2 Incorporate Li 6 P.S. 5 Cl replaces part of Li 2 S), its preparation method comprises the following steps:

[0053] 21.1849g of Li 2 S, 0.2137g of Li 2 o 2 , 7.8976g of LiCl, 20.7038g of P 2 S 5 The raw materials were mixed, placed in a 500 mL roller mill jar, 400 g of 10 mm yttrium stabilized zirconia grinding beads were added, and ground at 150 rpm for 24 hours until uniformly mixed to obtain a precursor. Take 2g of the precursor and press it into tablets, put ten pieces in a quartz tube with an inner diameter of 25mm and a length of 300mm, seal it, and calcinate at 550°C for 4h, and grind the calcined block into powder to obtain a sulfide solid electrolyte powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com