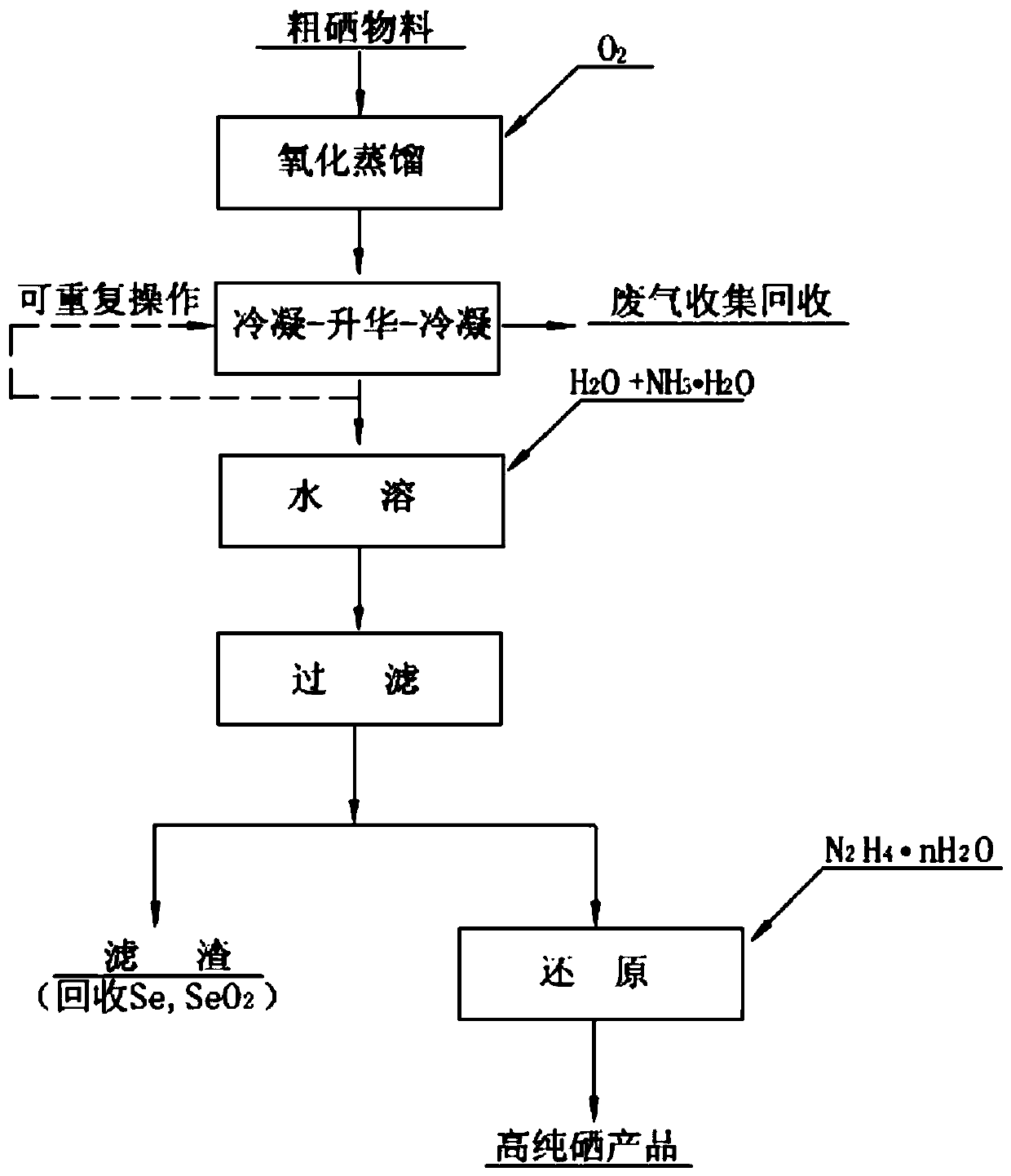

Method for preparing high-purity selenium from crude selenium product

A technology of high-purity selenium and crude selenium, applied in the direction of element selenium/tellurium, etc., can solve the problems of large reagent consumption, high production cost, and long process flow, and achieve simple and practical process, good selenium purification effect, and good environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A. Take 1Kg of crude selenium material from a smelter, its main components (mass percentage) are: Se 97.36%, Te1.28%, Cu 0.028%, Pb 0.014%. The material is crushed to a particle size below 3mm, dried and placed in a quartz tube furnace. Start the furnace to raise the temperature to 550°C, and at the same time turn on industrial high-purity dry oxygen, and the oxygen flow rate is controlled at 1L / min. When the furnace temperature reaches 550°C, keep it warm for 10 minutes, turn off the oxygen, and turn off the furnace to cool naturally;

[0026] B. arrange and collect the condensed selenium dioxide crystals, remove the slag in the furnace, and continue to heat up to 500°C in the quartz tube furnace for sublimation. When the furnace temperature reaches 500°C, keep the temperature for 15 minutes. Then lower the furnace temperature control to 200°C for natural condensation. When the furnace temperature reaches 200°C, keep the temperature for 10 minutes and then open the fu...

Embodiment 2

[0031] A. Get 2Kg of crude selenium material from a smelter, its main components (mass percentage) are: Se 98.32%, Te1.26%, Cu 0.023%, Pb 0.012%. The material is crushed to a particle size below 3mm, dried and placed in a quartz tube furnace. Start the furnace to raise the temperature to 575°C, and at the same time turn on industrial high-purity dry oxygen, and the oxygen flow rate is controlled at 1.2L / min. When the furnace temperature reaches 575°C, keep it warm for 10 minutes, turn off the oxygen, and turn off the furnace to cool naturally;

[0032] B. arrange and collect the condensed selenium dioxide crystals, remove the slag in the furnace, and continue to heat up to 550°C in the quartz tube furnace for sublimation. When the furnace temperature reaches 550°C, keep the temperature for 15 minutes. Then lower the furnace temperature control to 205°C for natural condensation. When the furnace temperature reaches 205°C, keep the temperature for 10 minutes and then open the f...

Embodiment 3

[0037] A. Get 3Kg of crude selenium material from a smelter, its main components (mass percentage) are: Se 98.97%, Te1.24%, Cu 0.022%, Pb 0.012%. The material is crushed to a particle size below 3mm, dried and placed in a quartz tube furnace. Start the furnace to raise the temperature to 600°C, and at the same time turn on industrial high-purity dry oxygen, and the oxygen flow rate is controlled at 1.4L / min. When the furnace temperature reaches 600°C, keep it warm for 10 minutes, turn off the oxygen, and turn off the furnace to cool naturally;

[0038] B. arrange and collect the condensed selenium dioxide crystals, remove the slag in the furnace, and continue to heat up to 600°C in the quartz tube furnace for sublimation. When the furnace temperature reaches 600°C, keep the temperature for 15 minutes. Then lower the furnace temperature control to 210°C for natural condensation. When the furnace temperature reaches 210°C, keep warm for 10 minutes and then open the furnace exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com