Integrated processing technology of landfill leachate

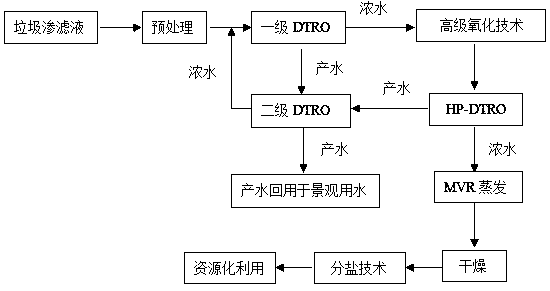

A landfill leachate and treatment process technology, which is applied in the field of landfill leachate integrated treatment process, can solve problems such as high salt content and complex components of DTRO concentrate, and achieve the effect of zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A domestic waste leachate, the main quality index PH=7.78, conductivity 18,000 μS / cm, CODcr: 6800 mg / L. The process is as follows:

[0022] Add acid to adjust the pH of the landfill leachate stock solution, and enter the quartz sand filter with a filtration accuracy of 50 um. The sand filtered water is added with scale inhibitor and then enters the security filter with a filtration accuracy of 10 um. The effluent enters the first-stage DTRO for filtration and concentration, and the concentration factor is about 5 times. The concentrated solution enters the electrolytic catalytic oxidation equipment for electrolysis, and the COD removal rate is 75%. The effluent from electrolytic catalytic oxidation enters 12 MPa HP-DTRO for filtration and concentration, with a removal rate of 99% and a recovery rate of about 40%. The high-concentration concentrated liquid is recompressed by mechanical steam to evaporate 80% of the water, and then dried to obtain miscellaneous salts. ...

Embodiment 2

[0024] For the leachate of a landfill, the water quality indicators are: PH=8.24, conductivity 42,000 μS / cm, CODcr: 5360mg / L. The process is as follows:

[0025] Add acid to adjust the pH of the landfill leachate stock solution, and enter the sand filter and security filter for treatment. The filtration accuracy of the sand filter is 100 um. The sand filtered water is added with scale inhibitor and then enters the security filter with a filtration accuracy of 10 um. The effluent enters the first-stage DTRO for filtration and concentration, and the concentration factor is about 4 times. The concentrated liquid enters the three-dimensional electrolytic catalytic oxidation equipment equipped with detrital activated carbon filler for electrolysis, and the COD removal rate is 82%. The effluent from electrolytic catalytic oxidation enters 12 MPa HP-DTRO for filtration and concentration, with a removal rate of 99.9%. The high-concentration concentrated solution is recompressed by m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com