Cabin structure of aircraft, aircraft and flying car

A technology of flying cars and aircraft, applied in the field of aircraft, can solve the problems of complex structure of the aircraft cabin, large space and heavy weight of the aircraft, and achieve the effects of weight saving, reasonable space layout, and convenient disassembly and maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

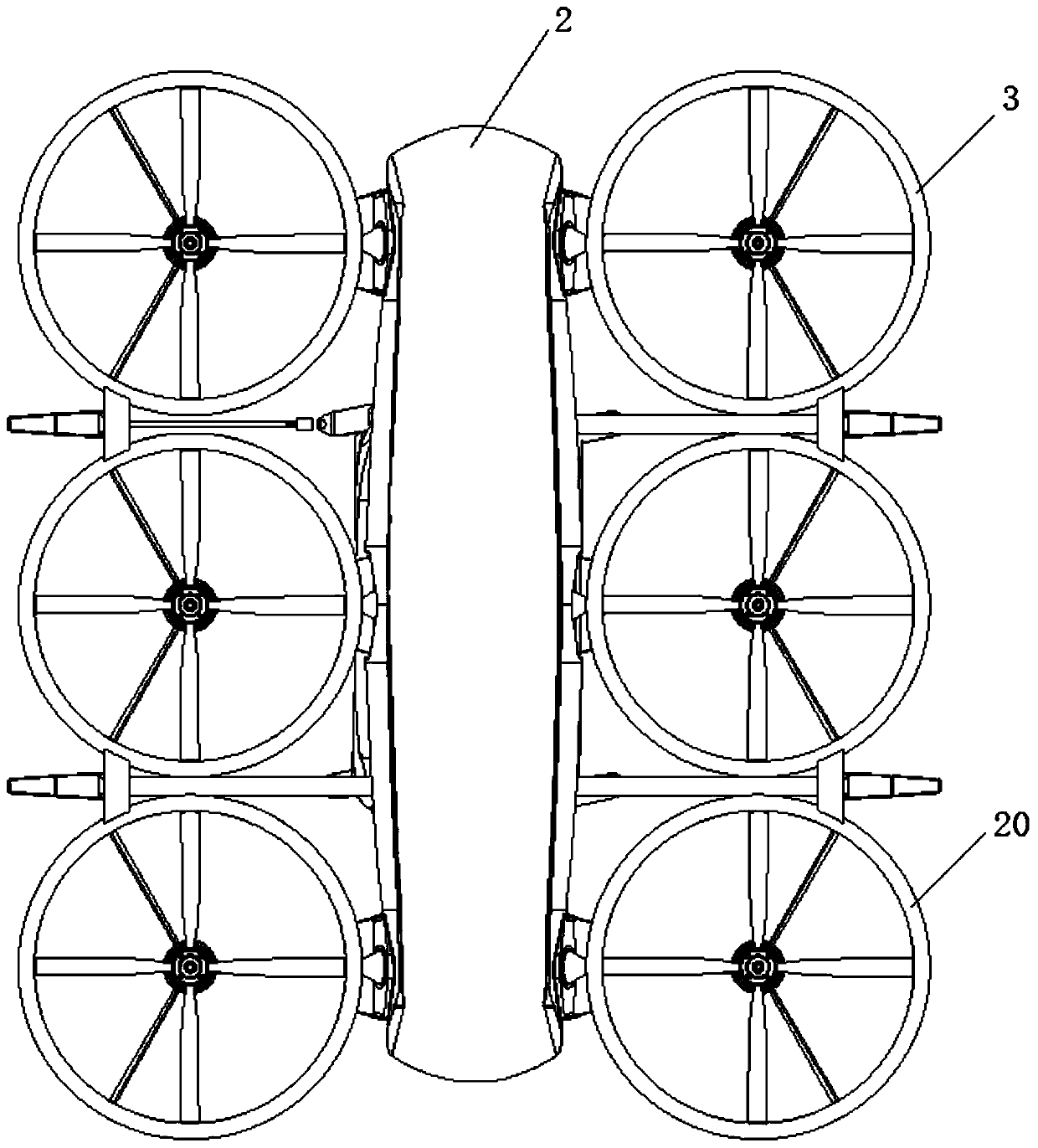

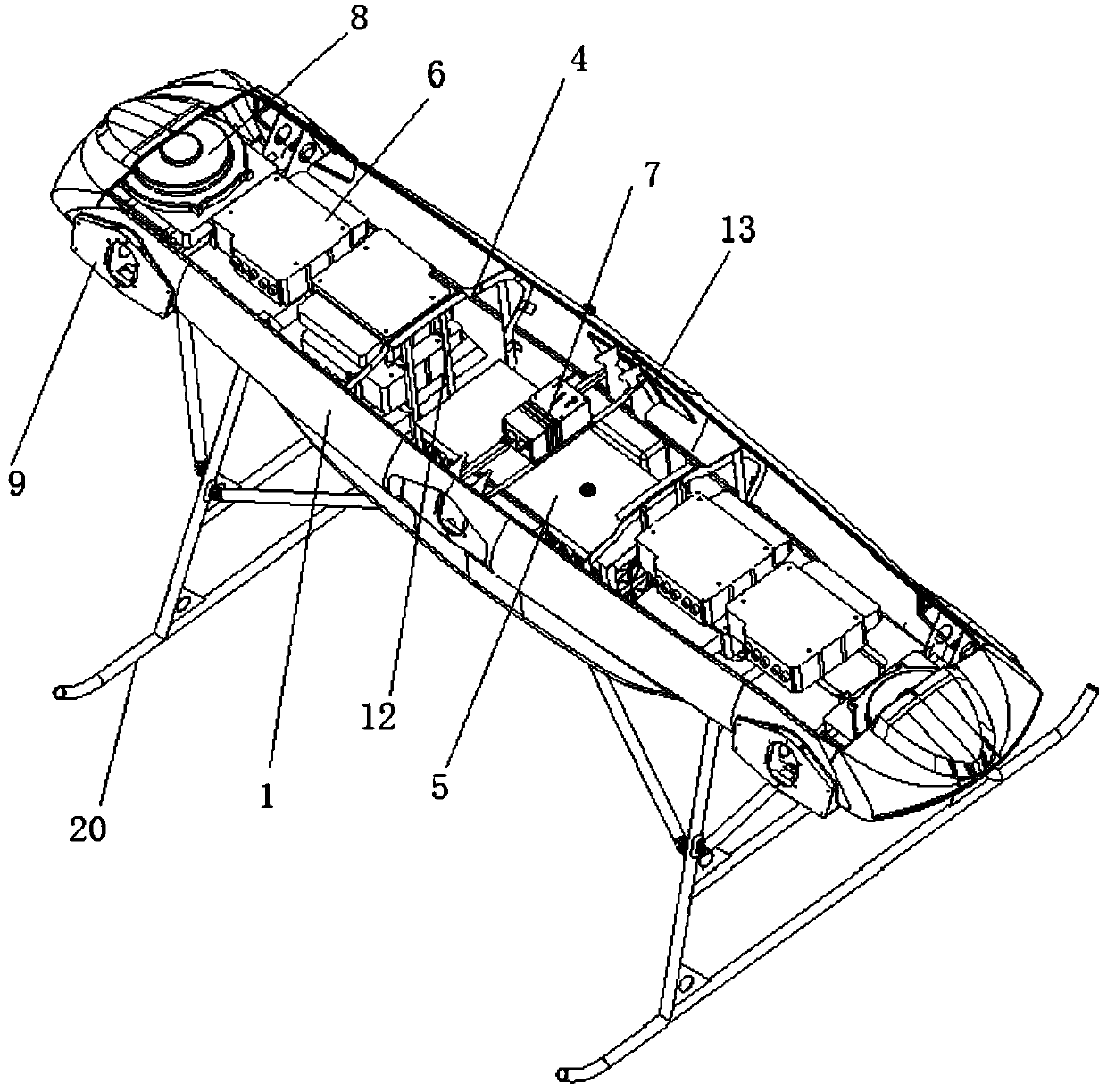

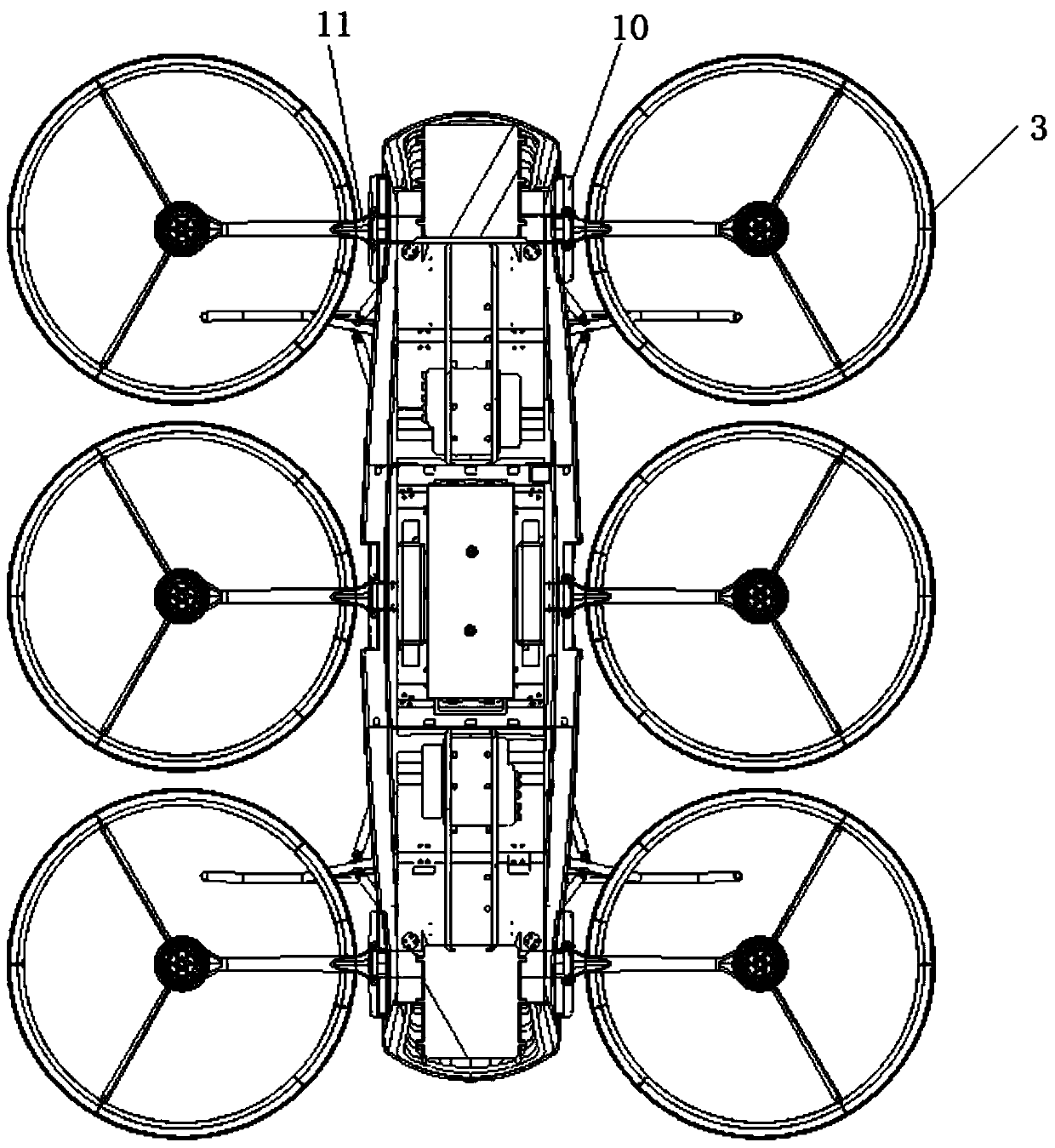

[0034] Embodiment 1, see attached figure 1 , 2 , a cabin structure of an aircraft, which comprises: a cabin shell 1, a hatch cover 2, a power unit 3 symmetrically arranged on both sides of the cabin shell 1, a partition frame 4, a battery pack 5 are arranged in the cabin shell 1 , motor controller 6, flight control device 7 and cooling device 8.

[0035] The nacelle shell 1 is a horizontally and vertically symmetrical structure, preferably elongated, with a streamlined aerodynamic shape; the top of the nacelle shell 1 is provided with a large-span hatch; the hatch cover 2 is arranged at the hatch; The bottom also can be provided with landing gear 20.

[0036] The power plant 3 includes at least two ducts or rotors distributed on the outer periphery of the nacelle shell 1; the number of ducts or rotors is an even number, which can be symmetrically distributed on the left and right sides of the elongated nacelle shell 1, usually four Duct or rotor can meet the requirements of...

Embodiment 2

[0042] Embodiment 2, on the basis of Embodiment 1, the cabin shell 1 is further limited:

[0043] The cabin is a semi-monocoque structure. The semi-monocoque structure includes a partial skeleton and a cabin shell 1 capable of bearing force. The strength of the semi-monocoque structure meets the requirements of use, and the quality is not too heavy, which reduces energy consumption. . The cabin shell 1 adopts a honeycomb sandwich structure, that is, a honeycomb core material is provided between the inner and outer skins, and the skin and the honeycomb core material are connected by curing; the honeycomb core material can be made of paper or aluminum. In this example, the honeycomb core material is preferably paper, the thickness of the honeycomb core material is 4-15 mm, and the thickness of the skin is 0.4-1 mm. According to the rigidity and strength requirements of different positions, honeycomb core materials with different thickness specifications can be used in different...

Embodiment 3

[0046] Embodiment 3, on the basis of embodiment 1 or 2, the described bulkhead 4 is further limited:

[0047] See attached figure 2 , in this example, the bulkhead 4 is an inverted U-shaped structure, and is arranged at the hatch position, and is close to the front and rear ends of the hatch respectively, forming reinforcement at the hatch, which makes up for the gap caused by the opening of the hatch on the cabin shell 1. Strength weakening and structural deformation. Furthermore, in this example, four bracket columns 12 are symmetrically arranged in each bulkhead 4; one end of the bracket column 12 is fixedly connected with the bottom plate of the cabin shell 1, and the other end is fixedly connected with the bulkhead 4; The frame column 12 strengthens the frame 4, supports each other through the frame 4 and the frame column 12 to form a support frame, increases the stability of the frame 4 and the rigidity of the engine room, and meets the support requirements for each eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com